Hearing the word “sandwich”, only one thing comes to mind - a closed sandwich with a filling. And suddenly a “sandwich chimney”. Why is that? And it's simple: the chimney sandwich is made on the principle of “bread-filling-bread”, but instead of bread, pipes of different diameters, and instead of filling, a layer of fire-resistant insulation. This design helps to reduce the temperature of the outer layer of the chimney and to reduce the formation of condensation inside the chimney. Sandwich chimneys are used to remove combustion products from the room. It can be a stove, fireplace, bathhouse or system individual heating gas boiler.

In contact with

Advantages of the chimney sandwich:

- appearance - a sandwich chimney made of of stainless steelsmooth and shiny;

- condensation is reduced due to temperature differences;

- extended service life - pipes are made of durable stainless steel;

- the ability to independently install a chimney without the help of specialists.

Chimney sandwich pipes come in different diameters

Trade marking usually consists of two numbers - inner diameter and outer. For example, 110/180 or 120/180. The first digit is the working diameter, which is directly used to connect to the thermal unit, the second digit is the outer diameter of the pipe. How to calculate the required pipe diameter? The diameter of the pipe must be selected based on the power of the thermal unit: the more powerful the device, the larger the cross section must be chosen. Typically, the diameter of the pipe is indicated in the data sheet of the device. The main thing is that the pipe should not be in close contact with the ceiling, otherwise the air flow for natural cooling will be disrupted.

Pipe length calculation

The length of the pipe must be at least 5 meters. The horizontal part of the pipe should not exceed 1 meter in length. Depending on which angle you want to make, bends are used at an angle of 15 to 90 °. Best of all, if it is an angle of 90 ° - then the wind will not blow out the heating unit. The outer part of the pipe must be at least 50 cm above the roof ridge if it is located at a distance of up to 1.5 m from the ridge. If the chimney pipe recedes from the ridge by 1.5 - 3 meters, then it can be flush with it. In the case of a flat roof, the chimney pipe should be located 50 cm above its level.

Choosing a chimney sandwich pipe

The main thing to pay attention to:

- steel thickness - the thicker, the stronger and more durable your chimney will be;

- check the connecting elements - they should not be defective, especially poorly welded seams and damage to the shell;

- the pipe must not be deformed and wrinkled, the shape of the pipe and elbows must be clear and even, otherwise the tightness will be broken, and the smoke will calmly enter the room

- you can ask the seller to connect the pipe to a knee or tee - the connection must be strong, should not hang out;

- do not chase cheap pipes - you need to put quality ahead of other properties.

Preparation for installation

The most important thing is to buy all the necessary material. No special fixtures are required. The heating unit on which the chimney sandwich is installed must be fully operational. After the installation of the chimney, the unit can no longer be moved from its place, so check its operability and installation strength in advance. The unit must be fixed, firmly fixed to the floor. If the unit has already been operated, you need to remove the old chimney and thoroughly clean the soot outlet.

Getting to work

The chimney starts from the heating unit. However, the first element of the chimney should not be made of a sandwich pipe, since directly at the outlet there is a very high temperature of the gases. Sometimes the height of the flame can reach the chimney. Therefore, the first bend of the chimney is made of ordinary stainless steel.

Very often, an improperly arranged chimney creates a fire hazard in a residential building. The combustion products of the fuel are not completely removed from the premises and cause carbon monoxide poisoning of the body. Sometimes, due to neglect of the technological features of the work, smoke occurs and reverse thrust is obtained.

Steel chimneys and their properties

There are many varieties of materials for the installation of the chimney in private homes. Pipes are divided according to purpose and functionality.

Chimney Sandwich

Insulated double-layer pipes they allow the inside to heat up as quickly as possible and contribute to the effective removal of smoke from the combustion zone. They are arranged outside the building in cases where it is not possible to perform the internal wiring of the chimney.

The installation of a chimney sandwich can be ordered by specialized builders, but if you understand all the intricacies of the technology, you can install the chimney yourself.

Positive characteristics of the stovepipe sandwich

How to choose a chimney sandwich

When buying smoke exhaust elements is required factory certificate with a description of its characteristics, which include the name of the categories of boilers for possible connection, the warranty period and types of fuel. In the absence of a certificate, use the right to purchase elsewhere.

When buying smoke exhaust elements is required factory certificate with a description of its characteristics, which include the name of the categories of boilers for possible connection, the warranty period and types of fuel. In the absence of a certificate, use the right to purchase elsewhere.

For craftsmen who want to create a smoke exhaust with their own hands, there should be detailed instructions.

Pay attention to the stainless steel of which the sandwich is made. The quality of this material affects the service life and resistance to high temperatures.

The heat insulator inside the cavity must withstand up to 650º without deformation.

For solid fuel boilers, products with joint joining by laser welding and stainless steel inner pipe. For boilers using gas fuel it is allowed to connect the elements using the skating method and the cavity inside each of the galvanization.

External elements can be made of galvanized steel, polyester, brass, stainless metal.

Stainless Steel Sandwich Sizes

When buying pipes, it is necessary to take into account the diameter of the outlet pipe from the boiler. The corresponding indicator of the pipe should not be less than it. Sandwich pipe should be worn on the pin.

Features of the installation of chimneys

Double-walled sandwiches solve the problem of condensation on the walls of the chimney in the cold due to the insulation included in the design. Such isolation prevents soot formation on the inner surface and increase the service life.

To facilitate the assembly of the prefabricated structure, shaped parts are produced for connecting, turning the channel and other functions.

Varieties of elements for assembly

- The main length of the chimney is carried out in segments of 1 and 0.5 m.

- Horizontal sections (beds) are connected using revision tees to eliminate clogging of the pipe.

- A tee for collecting condensate and cleaning the internal cavity is installed at the beginning of the vertical section of the channel. Often this happens immediately after the chimney exits to the outside of the building. One of the exits of the tee is made opening on the thread to remove condensation moisture.

- Corners for a 90º chimney swivel device are made of pipe materials and insulated with an insulator layer.

- Compensator for a smooth change in the linear dimensions of the sandwich with changing temperatures. In high-rise buildings, it is installed on each floor, and in single-story buildings above the floor.

- The design of the adjoining to the roof is designed as one unit and serves to design the exit of the chimney channel to the roof.

- A node to eliminate leakage in the outlet of the roof. Installation is carried out around the chimney.

- Tip to protect channel openings from debris, snow and dust.

How to assemble a chimney

Outdoor assembly. The first step is a horizontal pipe section from the boiler. A steel sandwich is attached to the chimney pipe using prefabricated fittings that are attached to each other with clamps and crimped. In the middle of the distance of the horizontal section, a tee is inserted for revision.

Outdoor assembly. The first step is a horizontal pipe section from the boiler. A steel sandwich is attached to the chimney pipe using prefabricated fittings that are attached to each other with clamps and crimped. In the middle of the distance of the horizontal section, a tee is inserted for revision.

The connection of the subsequent pipe is done by putting on the previous one. You cannot change the orderotherwise the smoke will enter the room.

The horizontal part of the pipe is lowered from the boiler by 3-5 cm so that condensate does not enter the boiler.

In the sandwich passage through the wall, insulation is made of non-combustible materials. If the pipe passes through a wooden wall, then it is additionally wrapped with a layer of asbestos. In brick, concrete and clay walls, it is enough to isolate the lumen with polyurethane foam for outdoor use.

Sandwich pipes cannot be connected at the exit point through the wall. If you accidentally hit this place, it becomes pipe trimming before the passage, then a whole section of the sandwich is embedded in the wall.

After the chimney exits the wall, a tee is immediately placed on the street to collect condensate, then the pipe is turned upward. The sandwich is mounted on the wall by attaching to a supporting truss that is mounted dowels or anchors.

The chimney is assembled to a height above the roof of at least 0.5 m. The pipe is fixed every couple of meters, but sometimes to prevent curvature and sagging of the chimney, fastening is performed more often.

The rise of the pipe above the roof depends on the proximity of the ridge to the exit of the chimney to the surface. If the pipe rises more than 2 m, then done additional mount it to the roof with a metal cable to give structural strength.

The device of the internal smoke channel

All connections are made similarly to the external assembly, only special attention needs to be paid to the passage of the chimney through the roof.

Sometimes, to equip the passage, a change in the design of the roof lathing is required. Interfering bars are cut out and transferred to another place. If we talk about interfering beams and rafters, then violating them is not recommended. In this case, the place of exit of the pipe is shifted. This applies to the option when the chimney is already in the finished building. In new buildings, such problems should not arise.

From below, a pipe is substituted for the prepared passageway, and is put on top of it special element of a branch pipe, which is fixed to the roofing using self-tapping screws. The junction with the roof is treated with mastic.

The element, in turn, serves as a support for putting on the outer pipe. Along the perimeter, this whole structure is crowned with a special stainless steel skirt. Assembly is being downloaded installation of the chimney head. After that, traction is checked.

When installing a chimney from a sandwich pipe, you need to take into account all the little things, so that then you do not endure troubles from smoke or carbon monoxide. Special attention should be paid for thorough sealing of joints and matching pipes in diameter.

When all installation rules are followed, the chimney will serve faithfully for a long time.

Sandwich Pipe Elements

Glad to see you again, dear reader!

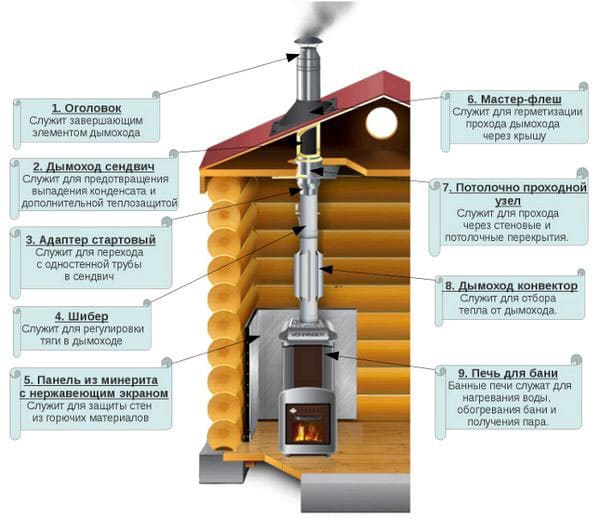

Any heating device, whether it is a fireplace, boiler or stove in a bath, requires installation. Much depends on how well this element is made. This is safety and good reliable traction in any weather and practicality with a beautiful appearance.

To date, the most optimal and advanced solution for the removal of combustion products will be a pipe sandwich for the chimney. But what the pipe sandwich is made of and how the installation of chimneys of this type is carried out, we will consider in more detail ...

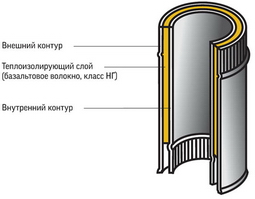

Installation of a chimney from a sandwich pipe

From the name itself, it is clear that “fashionable” chimneys consist of several layers, like a sandwich cake. Here is the inner diameter of the pipe and the outer. Between them is mineral fiber. As a rule, this is basalt wool or other non-combustible.

External and internal pipe sleeves are made of stainless or galvanized steel. The thickness of the metal can be 0.5 or 1 mm. This, of course, affects the price of the pipe and its durability. In all its characteristics, stainless steel is significantly superior to galvanizing, so draw your own conclusions.

Recently enameled sandwich chimneys have become popular. Special enamel not only gives a certain aesthetic appearance, but also perfectly protects the metal from high temperature, condensate and soot.

Modern design solutions can be very exclusive. Today we are moving away from those stereotypes that have been around for centuries. You can now position and remove the chimney almost as you wish: vertically, horizontally, under a slope.

Various elements of a chimney sandwich One of the options for installing a sandwich pipe

For ease of installation of such systems, a set of sandwich pipes may include the following components: umbrellas, headbands, support consoles, wall mounts, various clamps, rings and ties, angles and turns, gates (latches) and tees, ceiling and roof cuts, starting adapters and plugs. You can list for a long time, in a word - this is a "designer for adults" ...

Depending on the capacity of the installed boiler or furnace, the dimensions of the sandwich pipes are different. Here we can distinguish the following standard diameters of the inner and outer pipes, respectively: 110/200, 115/200, 120/200, 130/200, 140/220, 150/220, 160/230, 180/250, 200/280, 250 / 310, 300/380. All sizes, naturally in millimeters. The usual length of one pipe element is 1 meter.

Advantages and disadvantages of a chimney sandwich

Like any design, sandwich pipes have their own advantages and disadvantages. Of course, there are much more pluses and this is due to the original and practical device. As they say, all ingenious is simple. Here are some advantages of a sandwich pipe:- Due to its design features, sandwich chimneys have high fire safety

- Lightweight and compact design of the entire chimney. This does not require the organization of an additional foundation and as a result of unnecessary financial costs.

- Universal mounting options: really make any bold design decisions. Turns, bends, rounds of various obstacles, here is a common thing

- Possibility to remove the chimney through the ceiling or through the wall

- Due to the double circuit and insulation, little condensation is formed in the pipe. The absence of moisture inside the chimney contributes to not significant deposits of soot on the inner walls of the pipe

- Due to the smooth metal surface, good traction is formed in the sandwich pipe

- Simple and easy installation of chimneys

- Sandwich chimneys are virtually maintenance free. They are not susceptible to corrosion, have good smoke impermeability and excellent resistance to high temperatures, aggressive environments, etc.

Now about the shortcomings that still exist:

- Relatively high cost. A chimney of this type, especially with various "bells and whistles", will fly out in a tidy amount

- Relatively short service life: 10-15 years. Compared to masonry, the sandwich pipe serves much less

- Over time, temperature expansions and contractions can cause a slight leak in the flue duct

Sandwich Pipe Installation: Highlights

All work on installing a chimney sandwich begins with the marking and sawing of all the necessary technological holes. This implies a ceiling or wall, as well as the roof itself. It should be borne in mind that the distance from the pipe to unprotected wooden structures should not be less than 40-45 cm. For fire safety, let it be more than less. Otherwise, the use of protective screens is a must!

Options for a sandwich pipe for a bath

Installation of "designer chimney" begin to lead from the bottom up. First of all, a single-circuit pipe is installed on the furnace. Due to the lack of insulation, heat transfer is significantly increased. For example, a single-circuit sandwich tube for a bath can be equipped with mounted. It is possible to use a cylinder-shaped metal mesh for stones, which greatly increases the efficiency of the stove. The use of special economizer-convectors in the first segment of the chimney also enhances the heat transfer coefficient.

On the installed "single-circuit sleeve", the so-called starting adapter is mounted. It is needed in order to reliably and beautifully connect a single-stage pipe with a sandwich. Then a gate is mounted to adjust the draft level or a double-circuit chimney is immediately put on.

It is necessary to clarify this nuance: the assembly of a sandwich pipe can be carried out in two ways ("by smoke" and "by condensate"). "By smoke" is when the upper pipe is mounted on the lower. The smoke does not meet any obstacles. “Condensate” is the opposite: the upper segment is inserted into the lower. For optimal results, we dress the inner pipe sleeves “by smoke” and the outer ones by “condensation”. For the best sealing effect, it is advisable to use a special heat-resistant sealant and crimp clamps.

Calculate the height of the chimney to the ceiling in such a way as to exclude the joint of the segments in the area of \u200b\u200boverlap. This will increase the degree. And now the most important point. Many people consider the chimney sandwich to be the absolute standard of safety and do not install a passage duct in the ceiling passage, relying only on the thermal insulation of the pipes themselves.

The result is often very deplorable. The passage ceiling box is mandatory. It will protect wooden structures from heat and fire. It can be covered with expanded clay, but not sand. It is possible to use the same mineral wool as a heat insulator.

Passing the chimney through the roof, it is wise to use an element such as flash master. This is a special sealant of roof passages, which is called “flash drive” in common people. The element is necessary and practical, you can not do without it. A metal roof element is also used here, which ensures a reliable and stable position of the chimney.

Chimney support console

Chimney support console ![]() Remote enameled sandwich

Remote enameled sandwich  Ceiling Cut

Ceiling Cut

Depending on the design of the chimney, a “revision” is sometimes installed at the bottom. This element of the sandwich pipe is usually installed on an attached chimney, which has a horizontal section. There is a small door for. Very convenient and right time.

Spark arresters, diffuser umbrellas are installed on the top of the chimney. Purpose: to extinguish sparks and protect the pipe from precipitation and debris.

When installing a pipe sandwich for a chimney, it is necessary to exclude their touching various communications (electrical wiring, gas pipeline, water and sewer pipesventilation ducts). Following the manufacturer's instructions for assembling such a "designer", you can easily make the installation of a chimney from a sandwich pipe yourself. It will not be difficult, although you still have to “move your brains” and work with your hands.

Quote of wisdom: Who does not need someone else's, but lives independently, is richer than everyone.

The chimney pipe sandwich removes the products of combustion in a fireplace, stove or boiler, creates traction and ensures fire safety. Its installation does not take too much time and is made taking into account the characteristics of the room.

Two pipes embedded one into the other and having a heat-insulating layer in the middle are called a sandwich pipe. A special place is occupied by pipes made of heat-resistant stainless steel, they are less prone to clogging, easier to maintain. The heat insulator inside prevents condensation. Non-combustible materials are used in the form of insulation: basalt fiber or mineral wool. They are obtained from molten rocks, low thermal conductivity of the material is achieved due to the high air content in the mineral fibers.

Sandwich chimney

Advantages and disadvantages

Among the main advantages of sandwich pipes for the chimney are the following:

- light weight;

- speed of installation;

- the presence of smooth inner walls (improves traction and reduces soot formation);

- the ability to bypass the rafter system.

The main disadvantage: after 15-20 years, the insulating layer wears out, and the boiler loses its original performance. Moreover, the more often the equipment is turned off, the faster the chimney from the sandwich pipes fails.

Top mounted on the pipe head - protection against precipitation

Loss of tightness is a serious reason to replace the pipe. To prevent this from happening, purchase a quality product and trust the installation to professionals.

Device

The chimney is part of a looped system. It is through it that smoke is removed, due to which rarefaction occurs in the stove or in the fireplace and a portion of air is sucked in. Next, the cycle repeats again and again.

A brick chimney can only be built vertically, but sometimes there are situations when, due to the characteristics of the room, it is not possible to build a strictly perpendicular structure. In this case, the modular system will become best solution: with the help of transitions, knees, tees, you can get around an inconvenient place for cutting.

The inner diameter of the sandwich pipe is made of stainless steel, and the outer one is either galvanized iron or stainless steel acid-resistant grades. Therefore, the service life of the product is long.

Chimney device

When arranging a chimney sandwich, consider the following.

- The temperature of the incoming gases depends on the type of fuel used and the type of boiler. The higher it is, the more intensively the pipe heats up.

- You can lead the discharge pipe from the stove, fireplace or boiler through the walls of the room. This option is used when the chimney system is being erected in an already constructed building. For each heat generating device, it is better to build your own smoke channel.

- If necessary, it is allowed to mount no more than two deviations from the vertical plane with an inclination angle of not more than 30 °.

- The horizontal section has a limit of 1 m.

- The total height of the chimney to the top of the pipe should be 5 m. This creates the necessary draft and provides a vacuum.

- The distance between the wood (or other combustible surface) and the stove should be at least 50 cm.

- Unfair assembly may result in a fire.

Sandwich Pipe Size Chart

If the pipe passes through a wooden ceiling, a distance of 38 cm must be maintained from the inner pipe of the “sandwich” to the wooden element. All the space between them must be filled with fireproof material - galvanized sheet. The chimney pipe must pass through the entire ceiling, without joints. The chimney itself is mounted through the passage - metal box.

The options for placing and connecting chimneys are different. It depends on the conditions of the room in which you want to install. You can install a flue system during the construction of the house and after completion of construction work. Choose a place for the chimney so that when it is installed, the integrity of the house structure (logs, rafter system) is not violated.

System Installation Rules

The device is assembled according to the principle of the designer. The pipe must be inserted into the pipe to a length equal to at least half its diameter. The size of the chimney sandwich pipe determines its throughput.

Video: installation of the chimney

Types of connection

There are 2 ways to connect pipes: “through smoke” and “condensate”.

- "By the smoke"

The lower bend pipe enters the inside of the upper bend of the sandwich. In this case, the smoke freely moves up.

- "Condensate"

The inner top pipe is inserted into the bottom. And the opposite is true for the outer pipe: the lower one is placed in the upper one. Condensate moves down freely. This option is usually used in modern gas-fired boilers. In metal, cast-iron smoke temperature is about 300 °. Steam begins to condense at temperatures below 100 °. During the kindling, steam turns into drops of water, which rolls down into condensate collectors.

The second “condensate” assembly method is more acceptable. The passage through the roof is done in the same way as the passage through the ceiling. The gap between the rafters and the pipe must be maintained at least 150 mm.

Roof cutting makes the pipe outlet leakproof

Fire safety

In compliance with SNiP standards, you can be sure of the safety of the constructed structure.

- If the chimney is installed in a wooden house, butchering is used - fencing elements made of non-combustible materials. The dimensions of the cuts are as follows: 38 cm - to parts protected from fire, and 50 cm - to not protected.

- The building is protected with a layer of plaster of 25 mm on a metal sheet or mesh with fireproof materials (silica mats, basalt wool).

- An interval of 50 cm (if the beam is not insulated) and 38 cm (if the beam is protected by thermal insulation) must be maintained between the wooden beams and the chimneys located with them in the same wall.

- The chimney should protrude 50 cm or more above the top of the roof.

- The scheme of the chimney from the sandwich pipes is still at the design stage of the house.

Reverse draft and fire are the consequences of a rash choice of smoke exhaust system. But a modern chimney is not only durable and safe. It must withstand acid condensate and withstand the high temperature of the flue gas. Only in this case, the design will last a long time.

The term "sandwich" appeared in 1762. So called closed sandwiches in honor of Count John Sandwich. Nowadays, this term is used in structural materials as a designation of multilayer composite structures. The advantages of a composite of several layers are well known, it is increased structural strength, the ability to use soft or fragile material such as insulation, for example, as a core. The use of sandwich structures in construction is diverse. It is worth considering another application of a multilayer device - a sandwich pipe for chimneys. More details are in our material.

The chimney is a necessary element of the heating system operating by burning fuel, it provides the conclusion of fuel combustion waste: carbon monoxide and smoke. Working conditions can hardly be called light. Due to the fact that the height of the chimney reaches large sizes, the material must withstand high vertical loads, work when exposed to an open flame and high temperatures also makes its demands. In addition, the material must withstand constant temperature fluctuations outside the pipe surface and inside it.

The surface inside the chimney must be smooth and allow the chimney to be cleaned, since during combustion, in addition to gaseous products, soot and soot are also formed, which settle on the inner surface of the chimney, making it difficult to chimney and risk of fire and subsequent fire.

All requirements for chimneys correspond to a pipe sandwich for a chimney device. These pipes consist of an internal channel made of stainless, heat-resistant steel, coated with a layer of mineral insulation. On top of the insulation a protective shell is installed, made of stainless or galvanized steel or sheet metal coated with a powder protective coating.

The joint seam of the outer shell can be welded by automatic welding or fastened with a seam seam.

For the manufacture of the inner pipe, stainless alloy steels of the following grades are used:

- AISI430, relatively inexpensive stainless steel, normally withstands temperature fluctuations. Fastening is most often done with a seam weld, as this metal does not weld well;

- AISI439, titanium alloyed steel, which allowed to achieve increased heat resistance, has good anti-corrosion characteristics;

- AISI316, nickel-molybdenum alloy steel of high heat resistance, recommended for liquid fuel boilers and gas heaters;

- AISI304, a close inexpensive analogue of 416;

- AISI321, the most popular heat-resistant alloy steel, characterized by excellent anti-corrosion and heat-resistant characteristics;

- AISI106S, a relatively rare heat-resistant alloy, extremely high thermal stability characteristics, practically does not lend itself to corrosion. It is used for expensive products operating at high thermal loads.

It should be noted that for the outer shell they are used as galvanized carbon steeland inexpensive alloyed ones, the second option is more resistant to external factors, but at the same time, the cost of products with its use is quite high.

Mineral, non-combustible heaters such as mineral wool or basalt are usually used as insulation for sandwich pipes.

To connect the pipe modules to each other, one end of the pipe or reinforcement has a bell, on the other hand there is a corrugated narrowed region that serves to wedge in the socket and create a reliable connection that is impermeable to gas and smoke.

Chimney pipe sandwich - a luxury or a panacea?

The traditional materials for the chimney were brickwork, metal, ceramic and modern sandwich pipes for the furnace. The disadvantages of such chimneys are known, but it is worth comparing the advantages and disadvantages of various chimney systems:

- Brick chimney. The reliability and functionality of such a design depends entirely on its weight. Therefore, you need a reinforced foundation for the furnace. Brick chimney has a large weight, which affects its foundation, in addition, requires large investments in construction and maintenance. The construction of a brick pipe is a laborious and complex process. Bricks from the effects of temperature changes crumble and deform; over time, brickwork requires repair. Maintenance of such a pipe is also complicated, due to irregularities on the inner surface of the chimney, soot and soot begins to accumulate there, which must be periodically cleaned;

- Steel pipe, as a chimney. Again, due to the high temperature loads on the wall, its sufficient thickness is required, and the thicker the wall, the heavier the product itself. Moreover, steel, under the influence of temperature, can burn out, and condensate on its surface can lead to corrosion of the metal, and the subsequent failure of the pipe. The installation of such a chimney is also complicated, requiring either the use of an integral product, or the use of special connection methods, such as welding. The advantage of such a chimney device is its price;

- Ceramic pipes, clay mix productswhich has undergone heat treatment, has high heat-resistant characteristics, is quite well mounted. Durable The disadvantage is high weight and comparatively with metal, low strength characteristics.

- Chimney pipe sandwich. Lightweight construction consisting of separate, easy-to-connect modules. Installation does not require special equipment and experience. The design can be displayed in any direction, including in a horizontal or inclined position. It should be noted and the simplicity of the device: fasteners and individual modules. A chimney sandwich pipe consists of three layers: an internal channel of heat-resistant steel, a layer of insulation and an external protective pipe. The chimney itself is quite light, so fixing it will not cause any special problems. The inner surface of the pipe is smooth, made of heat-resistant alloy steel, which greatly facilitates its cleaning. Insulation will protect steel from condensation and corrosion. The outer, protective sheath serves to protect the insulation from environmental influences.

It is clear that the chimneys and chimneys of the sandwich construction are slightly more expensive than ordinary steel ones, but during the service life (which is 25 years), all expenses for the composite will pay off, because unlike steel, these chimneys do not burn out and do not rust.

Reviews about the sandwich pipes for the chimney are also sustained in a positive way. Users appreciated the ease of installation of the structure, its durability and appearance.

Related article:

From this review you will learn: varieties, average prices and design choices; rules, work requirements and features of the installation of the chimney, recommendations of specialists.

Dimensions of Sandwich Pipe Modules

A pipe sandwich for chimneys with a diameter of 115-120 mm is considered the main for a small country house or cottages. The heating system in such houses rarely exceeds 3.5 kW. For systems of higher power (from 5 kW), pipes with diameters of 180 mm are used, for heating systems with a capacity of more than 7 kW use pipes with a diameter of 220 mm. The range of sizes of the pipe sandwich for chimneys is wide and it is possible to quickly and easily select the required diameter according to SNiP standards.

When calculating the diameter of the sandwich, one should not forget about other elements of the chimney: fasteners, clamps, start sandwich, gate valve module, transitions through floors or walls.

But, not only the diameter of the pipe sandwich for the chimney matters, the module height is no less important. It is necessary to calculate the length of the chimney, taking into account the exit of the pipe above the ridge of the house to a height of up to 1.5 meters, the outlet height of the pipe depends on a number of factors and it must be selected individually, but on average the outlet length is 0.5-1 meter above the ridge of the roof. Sandwich pipe modules are available in several versions, distributed: 0.25, 0.5 and 1 meter high.