Ventilation systems are designed to supply a fresh stream of air to the house and to remove the exhaust naturally through leaks, gaps and openings, or forced-ventilation devices. The system complex includes a set of pipes specifically for ventilating the room. In case of their absence, there is an equivalent alternative - do-it-yourself ventilation from sewer pipes.

The value of pipes for the ventilation system

In the process of air exchange, about 30 cubic meters of fresh air should be supplied to each citizen living in a given living space. Provide it is required ventilation system. Pipes are the arteries of a complex ventilation mechanism. According to them, vapors, gases, odors are removed from the premises most susceptible to pollution (toilet, kitchen, bathroom, workshop, etc.). In the "safe" rooms (bedroom, living room, etc.) - served.

When organizing natural ventilation in areas with the formation of pollution for air movement, vertical channels are mounted with a roof outlet. According to them, stale air flow enters the atmosphere at a considerable height: the higher the pipe, the more efficient the draft. Log houses and frame buildings, as well as buildings where ventilation was not provided at the design stage, are equipped with plastic pipes.

With mechanical air exchange, the use of pipes is simply necessary. The system of pipes and shafts is supplemented by ventilation units for supply and exhaust. The forced system consists of a special pipe wiring of rectangular or circular cross-section. The supply is carried out to each room, producing air exchange in it.

Along with metal sleeves, plastic pipes are increasingly being installed. It can be both polyurethane and polyvinyl chloride. Type of pipe - medium and hard. The temperature of the passing air should not exceed + 70 ° C, otherwise the strength of the material is broken. This applies, in particular, to the hood from the kitchen. The recommended list of rooms where you can use pipes for sewage as ventilation:

- one-story residential buildings of a small area;

- production sites of small enterprises;

- garages;

- change houses;

- warehouses;

- corridors.

As you can see, these are objects where increased requirements are not imposed on ventilation, but it is needed, and the traditional air exchange system is too expensive.

Attention! If the installation of pipes is done by yourself, it is better if it will be sewer pipes for ventilation made of plastic with a cross section of 150 mm. It is such a diameter that can pass an air stream with a capacity of 30 cubic meters per hour through a 3 m high duct. If the pipe is lower, this will weaken the draft or even make ventilation ineffective.

Plastic pipes for ventilation: why you should choose

The air exhaust design can be made of polypropylene, polyethylene, polyurethane or polyvinyl chloride pipes. PVC pipe ventilation is the most popular of these types. It is mounted quickly, does not require special skills. Plastic pipes have many valuable characteristics:

- lightweight;

- silent during operation;

- do not react with chemical reagents;

- not subject to corrosion;

- strong and at the same time plastic;

- fire resistant;

- not exposed to UV radiation;

- dielectrics;

- with a long period of operation;

- there is the possibility of reuse.

- cost savings: plastic sewer pipes are significantly inferior in price to ventilation pipes.

The pipe composition is easily assembled using connecting parts (fittings). Their diversity makes it possible to arrange an air duct of any shape. Moreover, its sagging does not exceed 4%. You can always choose the desired section size from the standard series (mm): 100, 125 or 150, 200. But there are still non-standard (atypical) sizes. The inner surface of the pipes with a minimum degree of roughness does not allow to settle pollutants discharged with air onto the walls in the form of deposits.

Attention! The sensitivity of plastic to the effects of high and low temperatures can trigger pipe deformation and loss of stiffness.

DIY pipe system installation

- If sewer pipes are chosen for the arrangement of air exchange, then the entire duct must be assembled only from them. This will prevent the formation of a stepped structure inside the duct, which disrupts the movement of air.

- The future system is preliminarily schematically displayed.

- According to the scheme, markings are made on the spot.

- Be sure to put the dimensions for each section and the position of the fittings.

- The section of pipes is being specified. Standard sizes: round section 120 mm or square 150x150 mm.

- The diameter of the duct is calculated (you can use the online program).

- Purchased equipment, fasteners, pipes. When buying, you should be careful and consider that the documents give the size of the outer circle, not the inner one.

- The presence of all connecting and other elements is checked. For complete compatibility of the system parts and tightness of the joints, it is better to purchase from one manufacturer.

- Fasteners for future communications are fixed along the entire marked track.

- The pipelines prepared for installation are checked for defects on the outside as well as inside the pipes. They should be smooth with an antistatic coating applied.

- A riser is assembled from elements of a larger cross section.

- Air ducts are assembled and installed.

- Between themselves sections (branches) can be attached with one-piece or collapsible joints. The second method is preferable, because you can always disassemble the system for prevention.

- It will not be superfluous to seal all joints.

- Elements for connecting individual pipe parts are selected with unsharp transitions and without sharp corners.

- Ventilation sleeves are attached to the ceiling with clamps.

- They are interconnected using fittings of the required diameters.

- All pipe sleeves converge in one place at the highest point.

- With mechanical air exchange, fans, valves, etc. are installed.

- The common pipe is carried to the roof higher above the roof.

- The whole system is checked in operation.

Attention! Doubts - whether it is possible to make ventilation from sewer pipes - can only be when buying a product of dubious origin without certificates of conformity to quality. In all other cases, sewer manufacturers plastic pipes guarantee their complete safety for humans and the environment.

Plastic fan ventilation - a popular engineering solution for air exchange in the drainage system

In the case of using PVC pipes without warranty certificates in order to avoid the dangerous effects of substances released from them on people, it is best to make an exhaust sleeve out of them. This will exclude even accidental ingress of toxins into the room.

The decision to install ventilation using sewer pipes in a private house is economically justified. In addition, their operational characteristics do not cause complaints from users, even despite the fact that the auxiliary parts for collecting and fixing the system will need much more than with traditional ventilation “classics”.

In fact, the sewage system so that an unpleasant odor does not accumulate inside the house. Keep in mind that when you flush sewage into the sewer, a vacuum is created inside, due to which water is drawn through pipes and from accumulative siphons, which are present in every plumbing device in the house. Accordingly, due to the fact that the sewage system is not a priori hermetic, stench over time begins to seep inside the house and this creates inconvenience for living people. And the smell is so unpleasant that people get annoyed and start trying to find a source in order to clean it soon.

Installation of ventilation of the sewerage - the most important component of any private houseFirst, you need to make sure that the system is equipped with more than one siphon, because in fact these simple sumps are hydraulic locks that prevent odors from spreading while maintaining a vacuum inside. It is advisable that a siphon be placed in the drain after drainage - this is more reliable. There is another important reason, which also lies in the terrible smell emitted by the sewer. If there are several bathrooms in the house and one of them has not been used for a long time, the water in the mounted siphons has dried up for a long time and the vacuum is broken, since the valve does not work.

Therefore, it is important that the system is purged, otherwise the smell will quickly spread throughout the apartment. At the same time, standard classical ventilation, even with a forced fan, is unlikely to save people living inside. In this case, only a background pipe will help, which can supply heated air under pressure. It will tend upward and the smell will go out through it immediately into the atmosphere. Therefore, we will tell you what methods to build ventilation and which are better to use materials for this, we will pay attention to the main nuances of this difficult matter.

Technically Important Rules

As it has become clear to us that ventilation in the sewage system is mandatory, otherwise over time there will be problems that are not so easy to handle. Therefore, we highlight the rules that must be followed in order to understand what the device of this system looks like:

- The riser from the ventilation should go to the roof and rise above it to a level exceeding one meter;

- During installation, make sure that the exit from ventilation of this kind is located no closer than 5 meters from the nearest window;

- Plastic ventilation diameter should match the one laid in the house;

- In no case can you combine fan ventilation with the one that is laid in the house, otherwise half of the house will suffer from smells;

- Some masters recommend installing baffles at the end of the pipe, but this is not worth doing in this climate - it will freeze and become a problem for free air movement.

If you take into account these banal rules and do everything right, then the ventilation of the sewer risers can work correctly and prevent harmful odors from entering the rooms. We will talk further about what this technology is.

We select pipes and design a system

To make a hood you need to purchase pipes in advance, and it is better if you buy plastic pipes. Plastic pipes for ventilation are caused by several advantages:

- Light weight;

- Ease of installation;

- The ability to buy many additional elements at once - tees, corners, fasteners and brackets.

An important advantage that is observed here - they are put in place even by an untrained person using improvised means. While metal pipes ventilation requires not only skills, but also the mass of equipment that is unlikely to be found in every home. But with a plastic one, a man who knows how to hold a drill in his hands and imagines which end of the pipes are inserted into each other. Note that for a one-story house, pipes with a diameter of 50 millimeters are enough, while a two-story house will require 100 mm.

Installation of sewage ventilation from plastic pipes is easier than from metalInstallation of vacuum valves

According to the rules, the ventilation valve should not be placed in the sewer ventilation, but people decide not to spend money on pipes and installation and put these devices on. This happens due to a lack of funds for full-fledged ventilation ducts or due to the fact that it is too lazy to carry out, but the fact remains that it works, although it will not replace a full-fledged shaped pipe, but such a ventilation hole has a certain effect.

This kind of valve works surprisingly simple: when a vacuum forms inside the pipes, the valve opens and air is drawn in from the atmosphere. Then, when this happened, it turns out that instead of minus pressure, a pressure equal to atmospheric is obtained and the liquid does not flow out of the hydraulic locks, it closes and the smell does not come out - water does not. But at the same time, take into account an important rule, the valve is placed only at the end of the drain, closer to the exit to the central pipe. In this case, ventilation of a private house with your own hands will turn out adequate and efficient.

Cons of valve operation

Despite the fact that the system using such valves works quite simply and is considered to be a replacement for shaped ventilation, but there is one important minus. If the ventilation is made of plastic and the siphon has dried up in an idle room, the valve will not save you from such a development of events, you will have to put up with the terrible stench.

It turns out that if a private house suggests the presence of hydraulic locks and there is no water in them, there is no utility. And the supply ventilation valve can freeze in winter or plastic melt in summer, and it will stick to the hole. It can also rot from time and harmful chemistry with which it contacts in the process of work. Therefore, the installation of ventilation systems with similar valves is a double-edged sword, as if I did not want to save time and money - it would not work to completely replace the shaped pipe.

We make the valve from improvised means

It also happens that polypropylene ventilation is already in place and there is no time to install pipes and buy valves, it remains only to make the valve yourself. For this we need the following materials:

- Ballpoint pen spring;

- A pair of 45 mm screws;

- Plastic 5 by 5 centimeters, thin;

- Foam rubber the same size;

- Awl;

- Plastic tee that is used in sewers.

So, now we need to improve the exhaust device in a private house with a valve. First, make the valve body from the selected plastic, cut the circle. Now we take the foam rubber in our hands and cut out a dense disk from it. The first design is carefully glued to another, and as a result, a circle is obtained from which the foam edge peeps out. In order for the hood in a private house to work normally in the middle, we make a hole so that the selected bolt moves, it will act as a movable rod. Next in line is a plastic tee, we make holes in it in a circle, plastic ducts for ventilation in this case are better.

It is better if the diameter of the hole is no more than 5 millimeters, and in the center with an awl we make a small hole through which we carefully screw the self-tapping screw. The ventilation plastic pipe for the hood suggests that a spring with a piece of foam is put on the screw. Then we screw the lid into the tee and collect the prepared parts in such a queue: on the other side of the lid we screw the self-tapping screw. You need to twist until it rests against the valve and presses the valve to the drilled holes. After that, we screw the lid back and, when discharged, it turns out natural ventilation in a private house, air can get inside. And the valve will close when the pressure inside the system is equal to atmospheric - the spring will press the valve cover into place and close it.

How to ventilate a septic tank

If you have already laid pipes for ventilation in a private house, then you can not ignore the consideration of such a device as a septic tank. It also needs regular ventilation, so under certain conditions a fermentation reaction is created in it and the smell starts to squeeze out into the pipes under pressure. Therefore, exhaust ventilation through the wall to the street is needed to get rid of this effect. But at the same time, the septic tank also works on the fermentation reaction, so oxygen must necessarily get inside, otherwise such proper ventilation in a private house will not be able to function normally. If you omit the details of the operation of this device, ventilation is an important component that is necessary for proper operation.

In order to provide an adequate flow of air, a shaped pipe is suitable, which is placed as a continuation of the riser. At the same time, another ventilation system of a private house is needed so that there is a pressure differential between the atmosphere and the level of the septic tank. If there is a septic tank in the house, which includes only one chamber, then side devices are not needed, not enough densities of the lid that allow air to pass through. If the device is more complicated, it requires the installation of a fan pipe, it is desirable that it be bought plastic. The fact is that they are quite light and durable, moisture and dampness do no harm, and they are resistant to aggressive substances. In addition, it is much easier to install such pipes than to weld steel or cast iron, even an unprepared person can handle it. Keep in mind that the normal operation of the sewage system is the key to a comfortable stay in the house, so try to make this system adequate.

WATCH THE VIDEO

To summarize

So, we examined the nuances of building sewer ventilation in the house, now let's say a couple of tips that will help to cope with this task easier:

- In apartments, it is better to ventilate the sewer through the risers, the exhaust pipe should go half a meter from the roof so that the wind carries away harmful odors away;

- In the layout, consider that the diameter of the drain is equal to the diameter of the sewer. Also, for convenience and at will, it is allowed to connect several risers into a single hood;

- It is forbidden to connect the fan pipe with a chimney or ventilation of the house;

- It is better to abandon the deflector even if you recommend using this device. It causes condensation in the pipes;

- If the fan pipe comes out under the roof from below, then keep in mind that the pipe will easily break in the winter with snow, so make sure that the snow does not move out;

- Take the pipe away from the windows and balconies of other people, otherwise in the future they will come to you with complaints.

Now you are ready, after reading the article, get down to business and make the sewer better.

There is an opinion that sewage ventilation in a private house, the scheme of which is developed at the stage of building design, is necessary only for large cottages with several floors and a large number of plumbing installations. In fact, it is necessary to ensure the flow of air and the removal of gases generated for any sewage system, although the design may have significant differences depending on individual conditions. The presence of ventilation, in the first place, allows for a balance of pressures in the sewage system. Due to this, unpleasant odors and the appearance of unpleasant sounds of water absorption during the formation of low pressure zones can be avoided.

Do-it-yourself ventilation of a sewage system in a private house can be performed regardless of the number of storeys of the house and the number of drain points, it is only important to develop the scheme correctly. There are two possible options - using fan pipes and using vacuum valves. Before making a choice, you should know that the current building codes list the conditions under which it is necessary to install fan pipes.

These include:

- the presence of several floors in the house with the placement of drain points above the level of 1 floor,

- diameter of risers more than 0.5 m.

In other cases, the homeowner has the right to confine himself to a simpler scheme, but experts emphasize a marked decrease in the efficiency of sewage systems when using only valve devices. Whether the ventilation of the sewerage is necessary in a private house using fan pipes, if its presence is not necessary according to the rules, the homeowner decides, but he must take into account that the valves are not a complete replacement and are not able to guarantee the prevention of smell or extraneous noise.

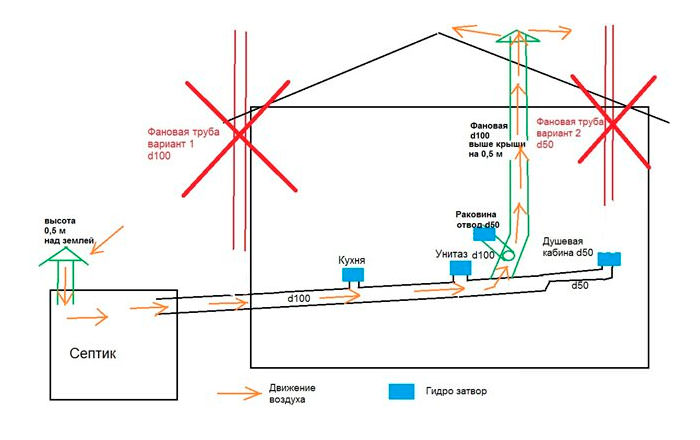

In the photo there is a diagram of the sewage hood in a private house with a ventilation pipe when using a septic tank as a treatment plant

Exhaust ventilation

In addition to the advantages listed above, ventilation systems with fan pipes ensure the correct operation of the sewage system, for which in this case drying out the siphons becomes less dangerous. If you have not used plumbing for several days and the siphon (water lock) has dried, if there is a ventilation pipe in the system, warm air from the sewer will rise and exit up the pipe. Since dry siphons cannot fulfill their functions as a hydro-barrier between the sewer and the room, in the absence of a fan pipe, odors will enter the house.

Installation Rules

The ventilation pipe may be of the same material as the sewer. This makes it easy to seal joints. Due to the low weight, which is important during the installation and operation of vertical structures, plastic products are often chosen for these purposes. When choosing, you should also consider that the diameter of the ventilation outlet must not be less than the diameter of the largest riser.

Following certain rules, it is not difficult to understand how to make sewage ventilation in a private house.

- Risers and fan outputs are connected into a single system. At long distance it is advisable to install several fan pipes horizontally between the individual risers.

- It is advisable to carry out installation of the sewage system at the construction stage. This will reduce the complexity of the work and make the system more convenient.

- When erecting a building for the installation of a ventilation pipe, a special channel and hatches are organized. If the sewage system and its ventilation are arranged in an already built house, the line can be laid not through the floors (this option can reduce the strength and reliability of structures), but through the wall.

- When sewer ventilation is developed in a private house, the scheme should provide for observing the distance from the outer pipe sections to the balconies and windows horizontally, at least 4 m, otherwise it cannot be guaranteed that unpleasant odors will not penetrate the house.

- The height of the outlet of the exhaust pipe to the roof depends on the design of the roof and varies from 0.2 to 3.0 meters. In particular, for flat roofs, it is enough that the upper part of the pipe is 300 mm higher than the roof level, and for a pitched structure, the height should be no less than 500 mm. And if the roof is used - 3 meters.

- If on the roof are displayed ventilation pipes from living quarters or chimneys, the sewer exhaust pipe must be higher than all the others to prevent unpleasant odors from the sewer into the house.

- Installing a deflector on the pipe does not increase the efficiency of the ventilation of the sewer system, but can cause the formation of ice from frozen condensate in the cold season.

Using Vacuum Valves

The installation of vacuum valves can become an alternative to sewage drains, however, professionals recommend choosing this option only if the installation of the sewer pipes is technically impossible or economically impractical.

Operating principle

The valve flap is connected to a spring having a small resistance, and a hermetic seal eliminates the passage of air if the device is in a closed state. If a vacuum occurs in the system after the valve (often it is caused by the discharge of water under pressure - flushing the toilet bowl or draining water from the washing machine using a pump), the valve automatically opens and passes air from the house into the sewer system, restoring balance. When the pressure equilibrium is reached before and after the vacuum valve, the sash closes again hermetically. Unpleasant odors cannot get into the room through a closed vacuum valve, and at the moment the sash opens, the air flow in the opposite direction prevents them from entering.

When installing equipment of this type, you should be aware of some of the nuances of operating such systems.

- The presence of valves cannot exclude the penetration of odors from the sewer system into the house if the siphons are dry.

- Vacuum valves are usually mounted on risers, however, if this installation method is difficult for any reason, you can install them on any of the horizontal sections of the sewage system.

Note: The installation of hydraulic locks in any case will increase the efficiency of the system, regardless of whether it uses a ventilation pipe or a vacuum valve.

You will find more information about in another article on the site.

We also have a separate, more detailed material about.

To avoid unpleasant odors, you definitely need to use a siphon. how to choose and install it in the kitchen.

Custom ventilation solutions for sewer systems

Non-standard solutions, which at the same time do not contradict the safety rules and sanitary requirements, can be an option if the hood for sewage in a private house is installed after the building itself is built. Under such conditions, the implementation of the classical scheme can cause certain difficulties.

Installation on the external wall of the house

If the ventilation pipe is led out along the external wall of the building, from the side it will resemble an ordinary drain and will not spoil the view of the house. The only difference will be the height of the upper part, which in any case will be above the roof level. The diameter of the pipe for such fan sewage ventilation is chosen as the most common - 110 mm. When choosing the installation location, the requirements regarding the permissible distances between the fan terminal and the windows (balconies, loggias) specified above should be observed.

Fence Mounting

The installation of the fan pipe with its fixation on the fence actually has no differences from the installation on the external wall. The only feature is a greater distance of the ventilation outlet from the building. When choosing this option, it is important to take into account the location of the house and outbuildings on the adjacent plot. Do not give neighbors the inconvenience of smell from your sewer.

Ventilation to a septic tank

A sewage ventilation system in a private house, led to a septic tank, in some cases may be considered the best option. Cleaning devices and drives, according to the rules, must be installed at a certain distance from the house (depending on individual conditions - from 5 to 20 meters). This allows guaranteed elimination of the likelihood of unpleasant odors getting into the house. In addition, a similar conclusion is easy to arrange and the field of construction of the house, when repairing and improving living conditions.

Before choosing the most suitable ventilation scheme for the sewerage of a private house, it is necessary to carefully study all the existing conditions and nuances of operating the existing sewer system.

0

Using a well-maintained toilet in a country private house is always more convenient than "amenities in the yard."

However, in order for the smell from the pipes and the septic tank not to penetrate into the rooms, you will have to take care of the ventilation system of the sewer system.

Ventilation of sewer risers is provided by a system of plumbing devices that allow liquids and air from the bathroom to the sewer and block the return flow of gases and air into the room.

Why do we need sewage ventilation?

Imagine that the sewer system of the house is equipped in the simplest way: all toilets, sinks, bathtubs and bidets are connected to the septic tank by pipes through a common riser. How does such a system work?

When flushing from the toilet, feces enter the riser, and then into the septic tank. The septic tank is not tight, so the air displaced by feces is released into the atmosphere on the street, and unpleasantly smelling gases are reliably cut off by water in the hydraulic lock.

When flushing from the toilet, feces enter the riser, and then into the septic tank. The septic tank is not tight, so the air displaced by feces is released into the atmosphere on the street, and unpleasantly smelling gases are reliably cut off by water in the hydraulic lock.

However, this only happens if the volume of the washed liquid is small and does not fill the entire lumen of the riser.

If the volume of the liquid is large (for example, when water is discharged from the baths at the same time on two or three floors), a piston will form in the riser from the liquid, which drops down.

As in any piston pump, this will cause rarefaction of air above the piston and the suction of water from all the hydraulic locks of plumbing fixtures to the riser and then to the septic tank.

After such a discharge, polluted air with an unpleasant odor freely penetrates through all plumbing fixtures into all bathrooms at once.

This effect is most pronounced with the rapid pumping of the contents of the septic tank into the sewage machine.

Unpleasant smell in the house is not limited to. During the decomposition of feces in a septic tank, gases hazardous to humans are formed: hydrogen sulfide and methane.

Thus, the ventilation of the sewer risers must constantly remove gases from the system into the atmosphere and reliably block their penetration into the room when draining and pumping the contents of the septic tank.

Elements of the ventilation system

The ventilation system of the sewage system includes three elements:

- water seal;

- air valve;

- fan pipe.

- this is a device in the form of a U-shaped pipe or channel, constantly filled with water and blocking access to gases from the sewer system into the premises.

- this is a device in the form of a U-shaped pipe or channel, constantly filled with water and blocking access to gases from the sewer system into the premises.

The siphon works according to the principle of communicating vessels: when the liquid is drained through one vessel, the second vessel overflows, and the drain to the riser occurs.

After the discharge, the siphon remains filled with liquid and reliably blocks access to gases from the septic tank.

A water trap prevents the appearance of an unpleasant odor in the rooms under the following conditions:

- constant filling with liquid;

- the absence of decaying organic residues in the plumbing fixture and in the siphon itself;

- the gas pressure in the riser should be equal to the air pressure in the rooms.

To comply with the first two conditions, it is enough to keep all sewage receivers clean and periodically fill their siphons with clean water if they are not used for a long time. Equal pressures are provided by other elements of the system.

- This is a device that allows air to enter the sewer riser and blocks the flow of gases from the riser into the premises.

- This is a device that allows air to enter the sewer riser and blocks the flow of gases from the riser into the premises.

In small one- or two-story private houses with bathrooms on the ground floor, the discharge of a large number of drains into a septic tank is rare. In these cases, aeration valve is quite capable of preventing the ingress of gases into the premises.

Install it on the upper end of each riser (usually in the attic). In this case, the ventilation pipe must be installed on a septic tank, which is simpler and cheaper.

The valve system cannot replace siphons on plumbing fixtures; it only supplements them. If the water dries in the siphons, an unpleasant odor still appears.

This is a ventilation duct connected to the upper part of the sewer riser and brought to the roof.

This is a ventilation duct connected to the upper part of the sewer riser and brought to the roof.

This element allows you to eliminate unpleasant odor from the sewer in the most radical way.

A fan pipe in a private house performs two functions:

- equalizes the pressure in the riser with atmospheric pressure when a large amount of effluent is discharged;

- constantly removes gases generated in the sewer system, preventing their accumulation and getting into the premises.

A properly designed and installed on the roof fan pipe for sewage almost completely eliminates the possibility of accumulation and penetration of sewer gases into the house.

Only in the case of drying out the siphons does an unpleasant odor still appear, but it is much weaker due to constant ventilation. It is best to use modern plastic pipes that are not subject to corrosion for the installation of the ventilation duct.

How to install

There are two prerequisites for installing a ventilation pipe in the sewage system of a private house:

- diameter of risers does not exceed 50 mm;

- the house has two or more floors and plumbing fixtures are installed on all these floors.

Since the installation of plumbing on floors is planned in advance in the project of the house, a ventilation duct for sewage should be provided in the same project.

The parameters and installation of the fan pipe are regulated by the Building Norms and Rules (SNiP 2.04.01-85 * “Internal water supply and sewerage of buildings”).

The rules for installing a fan riser are simple.

The height at which the exhaust part of the riser is discharged depends on the roof structure. She is:

- if the roof is not flat, 0.3 m;

- if the roof is pitched - 0.5 m;

- if the roof is operated (structures are located on it) - 3 m;

- if the channel is placed in a prefabricated ventilation shaft - 0.1 m from its edge.

The minimum distance from the exhaust part to windows and balconies is also limited. Horizontal it should be at least 4 m.

Flycars are not installed above the exhaust part of the risers (paragraph 17.18 SNiP), since in winter a large amount of frost from condensate is deposited on them, as a result of which the channel is blocked.

The deflector can only be installed if the house is built in an area with a warm climate.

Sewer ventilation is displayed on the roof separately from any other. The channel can be laid inside the prefabricated ventilation shaft, but it should not intersect with room ventilation or a chimney (paragraph 17.19 of SNiP).

The diameter of the fan pipe should be the same as the diameter of the riser. As a rule, the exhaust part and the riser consist of the same elements.

If there are several risers, they can be brought into one common exhaust part of the same diameter. In this case, the pipelines connecting the exhaust part must be installed with a slope of 0.01 (1 cm lowering per 1 m of length) towards the sewer risers (paragraph 17.20 of SNiP).

Any conscientious architect, when developing a house project, provides for the correct withdrawal of a fan pipe. However, many owners rebuild private houses after construction, changing the layout. In this case, problems may arise with the correct withdrawal of sewer ventilation.

If the roof is pitched, it is most reasonable to remove the exhaust part in the upper part of the slope as it does with a chimney. However, the toilet after redevelopment may be in a completely different place. Is it possible to transfer the sewer hood along with it?

The conclusion of the fan pipe at the bottom of the roof slope or even under the overhang of the roof does not make sense: in winter, snow falling from the roof can damage it. In this case, the ventilation pipe of the sewage system is led out under the roof to its upper part and only then the fan pipe is installed.

At the same time, the entire ventilation duct must be insulated so that condensate does not freeze in it.

If the exhaust part is slightly offset from the riser, they can be connected with a corrugated plastic sleeve. In extreme cases, the withdrawal of ventilation sewer risers can be done in the upper part of a blank wall in the backyard.

In this case, the pipe must be led out through an opening in the wall to a distance of 30–40 cm. If it is taken out into an opening closed by a decorative grill, condensate will precipitate over the hole in the cold season and damage the plaster.

Summary

It’s easy to mount the ventilation of the sewer networks of the low-rise private house system yourself, subject to certain rules.

When installing plumbing fixtures only on the ground floor, there is no need to mount a separate ventilation pipe for sewage. In this case, the effect of the water piston can be eliminated using an air valve mounted on the upper end of the riser.

If the plumbing fixtures in the house are installed on all floors, the uninterrupted functioning of the plumbing is ensured by a correctly installed fan pipe. Subject to the rules of SNiP, there are no problems with the operation of the sewer system.

There is serious debate about whether ventilation can be made from sewer pipes. Thematic forums are filled with various kinds of theorists and practitioners who give well-founded and not very good reasons in favor of one or another solution. There is no exact information both on the Internet and in the literature. To break through this information vacuum, this article will address the main differences between the ventilation and sewer plastic piping, its advantages and disadvantages. At the end of the article, a conclusion will be drawn that will make it possible to issue a certain verdict with a high degree of probability.

Material used

To create a high-quality ventilation system, manufacturers offer a ventilation pipe made of the following materials:

- PVC or PVC pipes.

- Polyurethane

- Polypropylene

- Polyethylene.

Regardless of the material, all products presented on the modern construction market have strength, integrity and environmental safety for humans. The shape and light weight, as well as the abundance of shaped products, make it easy to create ventilation networks of any complexity. The plastic used for their production is absolutely not susceptible to corrosion and aggressive gas environments. More often than others, PVC pipes are used to create ventilation systems. They are round and rectangular. Rectangular, mainly used to save space.

Regardless of the material, all products presented on the modern construction market have strength, integrity and environmental safety for humans. The shape and light weight, as well as the abundance of shaped products, make it easy to create ventilation networks of any complexity. The plastic used for their production is absolutely not susceptible to corrosion and aggressive gas environments. More often than others, PVC pipes are used to create ventilation systems. They are round and rectangular. Rectangular, mainly used to save space.

Bottom line: plastic ventilation pipes have a lot of advantages. It would seem, why use sewer pipes to ventilate your own home?

The following materials are used for the production of plastic sewer pipes:

- Polyvinyl chloride or PVC.

- Polyethylene.

- Polypropylene.

PVC products have a small wall thickness, which makes them quite light. For ease of installation, the product has a bell with a rubber seal. All sewer plastic elements, including fittings, have absolute resistance to aggressive environments. The smooth inner surface, the abundance of connecting and fastening fittings, makes such products by operational characteristics similar to ventilation ones. So is it possible or not to make ventilation from sewer plastic pipes? For this, it is worth considering the shortcomings of both “applicants”.

PVC products have a small wall thickness, which makes them quite light. For ease of installation, the product has a bell with a rubber seal. All sewer plastic elements, including fittings, have absolute resistance to aggressive environments. The smooth inner surface, the abundance of connecting and fastening fittings, makes such products by operational characteristics similar to ventilation ones. So is it possible or not to make ventilation from sewer plastic pipes? For this, it is worth considering the shortcomings of both “applicants”.

Disadvantages of PVC ventilation and sewer pipes

Plastic ventilation ducts have two drawbacks - low melting point and high cost. That is why in rooms with high air temperature, such pipes are not recommended to be installed. At 80 ° C, PVC ducts lose their stiffness and shape.

PVC sewer pipes also have drawbacks, despite the difference in price with ventilation pipes, which is from 2 to 5 times, depending on the manufacturer and the region.

- The low fire resistance of the pipes also does not allow their use for arranging ventilation in rooms with air temperatures above 60 ° C.

- They do not differ in special strength. The manufacturer tried to save as much as possible on the material, which gave a significant gain in weight and increased fragility of the product.

The polyethylene pipeline is devoid of these disadvantages due to the elasticity of the material. Although it is the elasticity of the material that makes the structure assembled from plastic parts not rigid enough. In the earth, special rigidity is not needed, but as a ventilation system, structural rigidity is an important indicator. As a result, we get that ventilation from sewer pipes will have almost all the same disadvantages as plastic ducts.

Sizes of sewer and ventilation pipes

Standard diameters of plastic ducts, ventilation equipment (diffuser fans, etc.), as well as connecting and fastening fittings are: 100; 125; 150; 200 mm. Next are less running, to create a ventilation system, dimensions.

Standard diameters of PVC sewer pipes and fittings are: 110; 160; 200;

Based on the above parameters, it is clear that they do not coincide with the standard diameters of the ducts. If you assemble a natural ventilation system using fan components of an appropriate size, then, in general, there should be no problems. But, if you have to dock with an existing ventilation duct, then there is a discrepancy. Such adapters do not exist in nature, and to make them artisanal methods is quite difficult and long.

Difficulties can be encountered when selecting fans and other equipment when creating a forced supply and exhaust ventilation system. Like air ducts, such equipment has standard “ventilation” dimensions, which means it will not fit in diameter.

Speculation and rumor

Rumor: According to the network, the opinion is actively spread that fan pipes used in the ventilation system will poison the air, as they are made of plastic containing poisonous substances. That is why they can not be used to equip the ventilation system.

All manufacturers of fan pipes unanimously declare that their products are absolutely environmentally friendly. It is impossible to confirm or refute this information, since the nuances of production are a commercial secret. But most manufacturers are ready to provide a certificate of quality for their products. So what - draw conclusions.

Rumor: Managers of many companies selling plastic ducts claim that sewer pipes are electrified, causing dust and dirt to stick to their internal surfaces.

When the air stream moves, a static electric charge may actually appear on the inner surface of the pipe. It is strange that this is said only about fan-made products. The thing is that they are electrified the same way, only they are processed in different ways. Many manufacturers of plastic ducts initially treat their products with antistatic, and some recommend doing this before installation. If the fan pipes are treated with antistatic, they will also cease to be electrified.

Conclusion: Ventilation in a private house from sewer pipes has a right to exist, since the advantages and disadvantages of fan products and air ducts practically coincide, and the main operational characteristics are confirmation of this. But they cannot be considered a full-fledged replacement anyway, due to difficulties with joining fan pipes with ventilation equipment. Do not forget about the dimensions. All fan connecting and mounting fittings, turns and bends are almost twice as many as their ventilation competitors. Decorative qualities, again, not up to par. The conclusion is made, and you decide what is more important appearance and compactness or final cost product.

Before you start arranging the ventilation system with fan pipes, think carefully, because the difficulties that you may encounter when installing fans, grilles or diffusers can cross out all the advantages of using this material.