When fuel is burned, carbon monoxide is produced in stoves and fireplaces. They are removed through the chimney. Despite the apparent simplicity, this design is complex. The chimneys are arranged in order to provide the necessary traction, so they should be correctly brought to the roof, determine the height and dock with the roofing. Properly made insulation for chimneys is also important.

Reasons for Insulating Chimneys

The furnace gases leaving the furnace to the outside have a high temperature. When they rush up the chimney channel, condensation forms on its inner walls. This leads to the following problems:

- if moisture is absorbed into the chimney material, then it collapses over time;

- sometimes droplets of water settle on the surface of the outlet channels, due to which their permeability decreases and smoke seeps into the room;

- in the event that condensate constantly drains down the walls of the chimney, smudges, hanging drops and an unpleasant odor appear.

Thermal insulation of the chimney helps to avoid these troubles and extends its service life.

Note! Chimney insulation is done in order to prevent its rapid cooling. If you make it illiterate, then you can’t count on a positive result.

Chimney heat insulation provides good traction

Methods of insulation of furnace channels

How to isolate the kiln channel depends on the material from which it was made. You can make insulation with:

- chipped bricks;

- slag;

- expanded clay;

- basalt or mineral wool;

- kaolin and others

After the containment device, the smoke exhaust structure is faced. For this purpose it is used:

- brick;

- slag concrete and reinforced concrete slabs;

- galvanized metal casings;

- wooden shields;

- profiled sheet, etc.

On a note! The easiest way is to buy a ready-made insulated sandwich pipe and install it at the stage when the chimney is made.

The method of insulation depends on the material of construction

We will get acquainted with some insulation options separately.

Basalt wool insulation

This method of protecting chimneys is attractive because it is used more often than others. Basalt cotton wool has a thickness of 20-100 mm and can withstand temperatures up to 750 degrees. This fire-resistant material is wrapped in several layers around the pipe and fixed with a wire. A layer of plaster is applied on top.

Facing the chimney with sheets of of stainless steel done in the following order:

- measure the perimeter of the pipe, including insulation;

- cut a piece of sheet steel up to one meter long and a width equal to the size of the structure perimeter plus an allowance for fastening;

- round the sheet and treat the edges with a roller;

- put the resulting form on the chimney, pull it and fasten it with metal screws;

- in the same way, install several more metal covers on top of each other (make sure that the seams run apart at an angle of 120 °).

On a note! If you do not use steel cases, the insulation will not last long, and you will have to replace it. Even if you insulate the chimney with foil or film, they will not be able to protect against penetration of moisture into the basalt cotton wool.

When insulating steel chimneys, a finished metal case is used

The use of kaolin

Another method of thermal protection of chimneys is the use of kaolin. The material is characterized as:

- not combustible;

- lasting;

- flexible;

- frost resistant;

- non-toxic.

Work on the installation of non-combustible thermal insulation for chimneys is carried out in the following order:

- first plaster the stove channel;

- then glue kaolin sheets to wet plaster;

- sew the chimney flue at the end with the facing material.

Kaolin for chimney insulation

Mineral wool insulation

Thermal insulation using mineral wool is done as follows.

- Build a metal profile crate around the chimney. The profile size is selected depending on the thickness of the insulation, and the step of the crate depends on the width of the insulating sheets.

- Attach mineral wool to the profile in several layers (do not forget to make a run of seams).

- Wrap the finished structure with vapor barrier film and glue the joints with tape.

Note! Sheets of metal corrugated board can be used as a finish. They are fixed to the crate using special screws with rubber gaskets.

Insulation of a steel chimney with mineral wool

How to isolate the chimney also depends on the material from which it was made.

Chimneys - the nuances of insulation

Thermal insulation of steel pipes

A chimney made of a round steel pipe is insulated with a finished metal case. In this quality, a galvanized pipe of large diameter is suitable. The difference in the diameters of the chimney and insulation is 16-20 cm. Thermal insulation is mounted in this way.

- Put the cover on the steel chimney.

- Pour expanded clay, broken brick or slag into the space formed between the elements. You can also tamp between mineral pipes, basalt cotton wool or fiberglass.

- Top fill the open area with cement mortar, waterproof it and install a protective cover on top.

On a note! Profile steel pipe sheathed with wooden panels or metal sheets (corrugated board). The distance between the components of the structure is 8-10 cm. The space is filled with insulation and reliably sealed from above.

DIY chimney insulation

Brick chimney insulation

In this case, preference is given to mineral wool, which is attached as follows:

- cut pieces from the heater, the size of which corresponds to the area of \u200b\u200bthe side walls of the pipe;

- attach the blanks to the brick using plastic dowels with round heads, or use adhesive tape (this option is light but not reliable);

- clad the attached material with asbestos-cement slabs, corrugated board or brick.

Important! To reduce heat loss, plaster the brick on the outside of the channel, and then cover it with a frost-resistant composition.

Brick chimney insulated with mineral wool

Thermal protection of asbestos-cement pipes

The isolation of chimneys from asbestos cement is done like this.

- First clean the outside of the chimney from dust and dirt.

- Make a folding metal casing, consisting of two halves. When assembled, its diameter should be 12-16 cm greater than the diameter of the pipe. The height of the case can vary within one meter.

- Put the lower galvanized cover on the chimney.

- Fill or tamper the protective material into the resulting space.

- Install the next case and put the insulation back on.

- Cut the upper casing together with an asbestos-cement pipe at a slight angle.

- Cover the insulation with a thin layer of cement mortar.

On a note! If you do not install a metal case, the mineral wool will get wet, become heavy, crumple or fray in the wind. The insulation is also taken away by birds, rodents or cats.

Asbestos-cement pipes are protected by galvanized casings

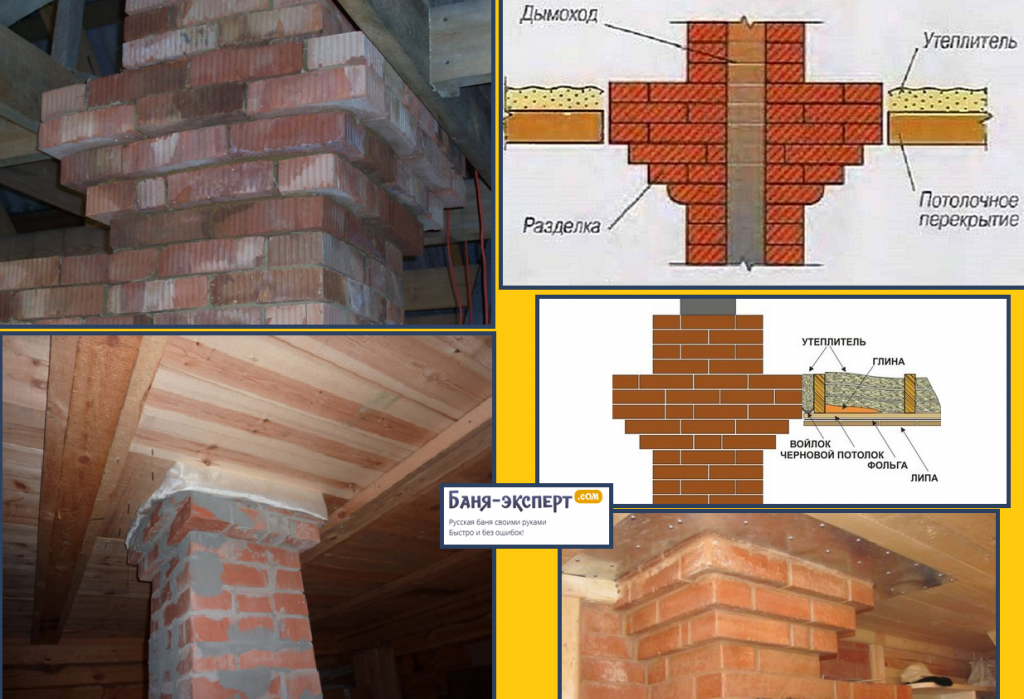

Chimney insulation in the ceiling

When a metal chimney passes through a wooden floor, the distance between them should be at least 30 cm. If the chimney is bricked, this value decreases to 10 cm. The opening is laid with basalt wool, and is closed with a metal sheet from above and below. Ensure that the chimney is firmly fixed to the ceiling.

Video instruction for chimney insulation

These are just some of the options for warming chimneys. Each stove-maker uses his own method. Let your chimney work smoothly!

One of the most important stages in the construction of a bath is the installation of a chimney. And insulation of the chimney of the bathhouse is an obligatory process during its construction, which pursues two goals: fire safety and corrosion protection.

If you do not make insulation, then under the influence of temperature drops condensation will form, gradually flowing inward and contributing to the destruction of the structure itself.

Insulated smoke ducts warm up faster, so the sauna stove works much more efficiently.

Depending on what the chimney of the bath is made of, various materials are used for its thermal insulation.

There are several varieties of already insulated chimneys for a bath stove, the most common of which are stainless steel sandwich pipes.

There are also ceramic sections that are already installed in expanded clay concrete modules.

And now about everything in more detail.

During operation of the sauna stove, its chimney is heated, and its inevitable proximity to combustible materials can lead to a fire.

The second, no less important problem is the appearance of condensation in the chimney. Condensate is the main enemy of all smoke exhaust systems.

This is not easy moisture formed on the walls of the chimney, and an aqueous solution of sulfuric acid, which can destroy any almost any material. It appears as a result of the passage of heated air through a still chimney.

As a result of the action of condensate on an uninsulated brick chimney, the masonry is destroyed, since it has the ability to penetrate into the microcracks of the brick, and when it freezes, it can expand. Metal chimneys are also very affected by condensation.

The metal of ordinary grades is not resistant to acids, therefore, it becomes unusable very quickly from exposure to condensate.

The only way to combat the occurrence of condensate is to isolate the smoke paths, in which the pipe will cool less and the sauna stove will quickly reach the operating mode of combustion.

Materials for insulation

Chimneys can be insulated using various methods, using non-combustible materials.

The most common are:

- Thermal insulation of the chimney with basalt wool and glass wool. Insulation materials used both for large surfaces of brick chimneys and pipes of a relatively small diameter. Available as a filler, in rolls or in the form of mats. For its use, the manufacture of an additional casing is recommended.

- The method of filling the space around the chimney with insulating material: expanded clay, slag, brick fight, special heat-insulating granules. This method involves the manufacture of an additional chimney casing.

- Plastering. This is the most common, until recently, method of insulation of brick chimneys. For this, a slag-lime solution was applied, applied with a layer of 5-7 cm on a reinforcing mesh. After drying, a sand-cement mortar of the same thickness was applied to it. But when heating and cooling the smoke removal system, such a heater cracked and required annual repair, so this method is considered unjustified from the point of view of labor costs and efficiency.

- Chimney insulation with modern foam polyethylene materials. "Teploizol" or "Folgoizol" is produced in rolls, has a low weight and good elasticity, is well cut, which makes it accessible to even non-professionals to work with it. This is the most simple and inexpensive way to insulate chimneys, widely used today.

The choice of insulation for the chimney

The choice of insulation, to isolate the chimney with your own hands, you need to approach carefully and seriously.

You should not buy the cheapest one, because it must have good thermal insulation properties, be convenient in operation, not require additional reinforcement of the load-bearing roof structures and ceilings, be non-toxic and non-combustible.

Stone or basalt wool is a wonderful thermal insulation made from basalt rock.

This insulation can withstand prolonged exposure to sufficiently high temperatures and does not burn, even when in contact with an open flame. In addition, it does not emit any toxic or unpleasant odors when heated. Such a heater can safely be called environmentally friendly material.

Glass wool is a type of mineral wool insulation made on the basis of waste from the glass industry. Between its fibers contains a large number of voids, so it retains heat well.

Glass wool does not burn and does not absorb moisture, and, in addition, is not subject to rot and rodents. It is not expensive and easy to use. Most often produced in plates and rolls.

Thermal insulation or foil isol are multifunctional types of insulation made of foamed polyethylene and coated with a sheet of aluminum foil. It is available in rolls and has a thickness of 2 to 10 mm. They can remarkably isolate the chimney of the bath, as these heaters withstand heat up to 150 ° -170 °.

We do insulation with our own hands

Chimney insulation using mineral, basalt or glass wool can be performed in two ways: insulation under the casing or insulation of the chimney without the casing.

In order to isolate the chimney using mineral wool mats, it is necessary to cut several pieces of slab from them that will correspond to the sides of the pipe from the outside.

Then, with the help of wire firmware, fix them in the chimney.

Important! There should not be voids between the insulation layer, otherwise the insulation will lose its effectiveness.

To isolate a metal pipe, you need to wrap it with basalt cotton wool and secure it with wire around the entire perimeter. After that, put on the chimney a second pipe of a larger diameter to get a kind of sandwich.

This method of thermal insulation of chimneys is the most effective and simple, but it allows to reduce heat loss by more than two times, as well as significantly reduce the fire hazard and the formation of condensate in smoke removal systems and protect them from destruction.

Thus, thermal insulation contributes to an increase in thermal efficiency and the safe use of furnaces. At the same time, it gives the building and the structure itself a more aesthetic appearance.

Having your vacation home, you need to take care of warming up the rooms in the cold season. A stove or other heating system needs a chimney flue. Smoke exhaust pipe is the main element of heat supply communications. For its effective functioning, it is necessary to insulate the chimney from the outside.

The relevance of thermal insulation

Moisture and smoke generated during fuel combustion are aggressive factors affecting a brick chimney. The difference in temperature during the cold season and the accumulated moisture settling on the walls fills microcracks with water, and the stone structure collapses from the inside. Small crystals of ice crush from the inside and destroy it. This can be eliminated by an insulated chimney.

In the process of combustion, condensate forms on the surface of the duct, which contains a chemical series of oxides. Interacting, the elements form weak acids (carbonic, sulfuric, etc.), which can destroy the metal surface. It is for this reason that chimney insulation is necessary.

Correct installation of thermal insulation can prevent a fire inside the premises and will not allow the roof overlap to catch fire. Well-heated chimney pipes improve draft in the fireplace, boiler, and stove; there is less residue of tar and burning in it. The efficiency of the heating unit is significantly increased.

Positive factors of insulated chimney

Before answering the question - how to insulate the pipe, it is necessary to highlight the advantages of an insulated chimney.

An insulated gas outlet protects the heating system from the effects of the external environment and combustion products. Of course, thermal insulation cannot completely protect the structure from destruction, but it will extend its operational life. This is due to the following factors:

- The pipe insulation allows you to maintain thermal balance in the middle of the structure, eliminating the possibility of aggressive acids and condensate falling onto the walls. Combustion products completely disappear with the smoke stream.

- Chimney insulation minimizes the possibility of temperature differences between the cooled chimney and hot steam.

- Energy-saving properties that contribute to fuel economy are increasing.

- The strength of the steam output structure increases due to the reinforcing frame.

Properly selected insulation of the chimney increases the frost-resistant properties of the system, ensures long-term preservation of the appearance and increases the operational life, which is very important.

The choice of material for thermal insulation

The main question of the owners of country houses with autonomous heating system - how to insulate the chimney. In order to reliably insulate the bends under the furnace or boiler, materials with a high degree of thermal insulation are used to ensure the heat balance of the chimney on the roof.

Basalt insulation

It is actual for warming a chimney of mineral wool or basalt. The insulation is obtained from a melt of volcanic rock - gabbo-basalt. It is converted into fibers, due to which the insulating material has advantages:

- retains up to 95% of heat;

- characterized by good permeability of escaping steam;

- differs in chemical and corrosion resistance;

- prevents the growth of fungus and mold on the surface of the chimney on the roof;

- vibration and heat resistant;

- made of environmental materials;

- not subject to destruction by ultraviolet radiation.

Stainless steel casing

Metal “armor” in the form of a pipe made of stainless steel is used as an insulation option. It is able to provide complete protection against mechanical damage, moisture and other aggressive factors.

The casing for the chimney is mounted on a pipe on the roof. The annular space is filled with basalt wool, the outside is covered with insulation, 5 cm thick. Asbestos chimney can be wrapped with this insulation.

Wood Shields

Wooden boards are considered one of the simplest options for warming a chimney pipe. Thermal insulation is made in the form of a wood frame from plates of the appropriate size. On top of it is a slate or other flooring from which the roof of the dwelling is made.

After the pipe is completely blocked by a tree, the empty cavity is filled with felt, slag, sand, mineral wool. Frame seams without fail are covered with a waterproofing composition.

Slag-reinforced concrete insulation boards

Insulation of the chimney in a private house with the use of iron and slag concrete slabs, provides the smallest distance between joints on the structure. The space inside and the corners are reinforced with mesh or wire, gypsum, clay and sand are poured in the form of a solution. Plaster is applied over the tile insulation.

The specifics of insulation

Warming the chimney with our own hands, we take into account that during the operation of the boiler, the temperature in the chimney can reach 200-300 degrees.

As insulation, it is better to choose a material with high heat-resistant properties: glass wool, mineral wool, basalt.

In the building materials market, thermal insulation is sold in the form of finished cylinders with a special foil screen. With their help, they draw up a flue and the adjacent roof elements - protecting them from fire and cold air. Tubular structures are sold in different diameters, which allows you to wrap oversized smoke exhausts.

Regulatory requirements for the installation of thermal insulation

Before you insulate the chimney pipe, you must make sure that it is installed correctly.

The flue is carried out in accordance with technological standards specified in GOST 52953-2008

- The exhaust pipe should be 5 m high. This indicator provides optimum draft in the heating system.

- Between the roof overlap and the outside of the boiler room, a distance of at least 250 mm is necessary.

- If the building is covered with combustible materials, in particular, slate, roofing material, ondulin, then the insulated smoke exhaust structure must be equipped with a spark arrester.

After making sure that the system is installed correctly, you can proceed to the subsequent work on the thermal insulation winding.

The main methods of insulation

The chimney metal pipe is isolated using various methods.

The method of warming a steel chimney

Chimney insulation is carried out using a special solution. The composition is prepared from a dry mixture and water. The solution is applied with a spatula to the surface, spreading over the entire area. Then, a fiberglass reinforcing frame on which the plaster is applied is fixed to it.

Gas boiler chimney insulation

The insulation for the pipes of a gas boiler should have a number of enhanced heat-insulating and heat-resistant qualities.

Sandwich structures block condensation settling on the surface while saving energy.

The chimney sandwich consists of a layer of mineral wool and two metal pipes. The upper element, with a larger diameter, is the main sleeve, the smaller one is part of the steam outlet channel.

How to insulate such a chimney pipe with your own hands? It is necessary to follow the recommendations:

- In the roof of the roof and ceilings make holes with a diameter of 25 cm larger than the chimney.

- At this stage, it is necessary to isolate the chimney pipe with a layer of basalt wool. The thickness of the winding should be at least 5 cm.

- The insulation around the pipe is fixed using steel wire.

- A larger casing is put on top.

Upon completion of work, the chimney is connected to a heating source and the surrounding riser is filled with expanded clay, clay or asbestos.

Chimneys for a bath

Chimney insulation in the bath is aimed at improving the heat transfer of the heating source, which is a stone stove.

Isolate the chimney in the steam room using the following options:

- thermal insulation - a material made of foamed polyethylene hidden between sheets of foil. Insulation rolls 2 - 10 mm thick are available on the market. Foil surface reduces pipe overheating. The insulation is wrapped around the chimney, fixing it with wire or metallized tape;

- filgoizol consists of two balls: a foil that saves over 90% of the heat in the room and a heat insulator. The material is used to cover the walls and ceilings of the sauna, providing the effect of a thermos;

- sandwich pipe, consisting of several sections. This option is suitable for saunas and baths with an iron stove.

Insulating a metal pipe means ensuring the optimal functioning of the heating system. Proper installation of insulation of chimneys with your own hands allows you to increase the operational life of the design and the heat generator, and also prevents fire.

The construction of a chimney canal in a private house requires compliance with the rules of sealing and fire safety. When constructing a chimney in a house or at the exit of a metal chimney in a bathhouse through the roof, chimney insulation is the main indicator of the correct organization of this unit of work.

The joint of the chimney with the ceiling and roofing materials remains a vulnerable area due to possible overheating and fire of the roof. To eliminate the likelihood of a fire, it is important to organize the insulation and sealing of the roof in accordance with all the rules.

Pipe insulation

The release of new building materials and the development of advanced technologies are a guarantee of effective thermal insulation. The choice of materials for this purpose largely determines the shape of the chimney, the method of wrapping the pipe that discharges hot gaseous substances during fuel combustion.

The main difficulty is not to allow materials adjacent to the chimney to become unheated so that they do not ignite in any type of building.

Most buildings in private households have a chimney coming from:

- solid fuel boiler;

- fireplace;

- ovens;

- cooking stoves.

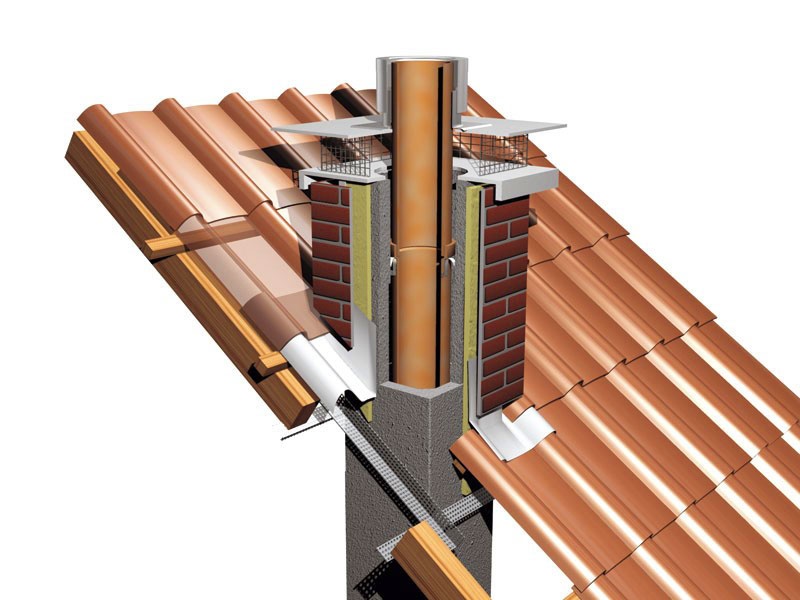

They have different degrees of load and the level of warming up to maximum temperature, but insulation is needed in each case. A prefabricated or modular chimney, manufactured as a sandwich system, involves the finished insulation of double pipes with a layer of basalt wool. It is effective for insulation, to reduce the likelihood of condensation, and as protection against overheating of roofing materials at the exit through the roof. It remains to properly organize the tightness of this passage so that moisture does not enter the house.

Ceramic chimney kit

Ceramic chimney kit Before isolating the pipe in a bathhouse or apartment building, it is worth choosing the option most suitable for your design. Ceramic chimney is no less effective and durable, used for a fireplace or bath. The assembly of the finished design includes components from fire-fighting materials. Some of them are adjacent directly to the pipe or cover it; others are designed to seal the passage through the roof.

The choice of location for the outlet of the chimney should be such as to facilitate insulation work. But the pipe should rise 30-40 cm above the ridge, in order to avoid reverse traction in strong winds, so the pipe is often led out through the ridge.

How to choose the right outlet for the chimney

Example of an external chimney outlet

Example of an external chimney outlet In houses of the old design, when all the chimneys were made of masonry, round pipes are led out through a square opening of the ceiling. The passage section in the ceiling is equipped with a special box made of wood or metal, observing a sufficient distance to the chimney.

It is important to correctly isolate this “window” so that all the gaps are filled and the materials at the junction are protected from fire. This clearance is filled with mineral wool, and special fire-resistant plaster is used. In a brick chimney, basalt and asbestos blocks are also used.

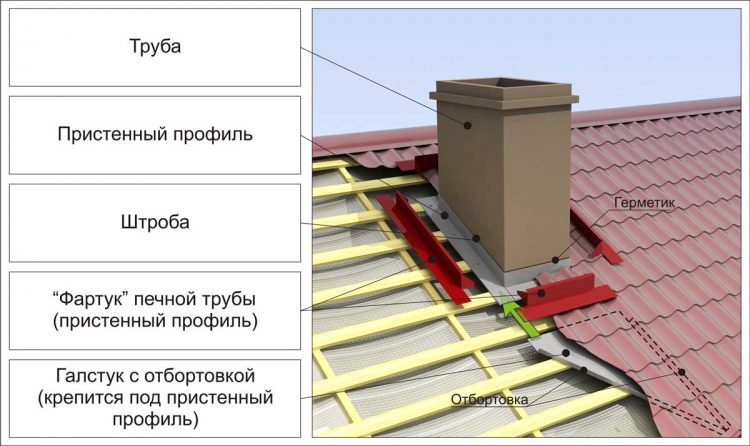

The safe and secure outlet of the chimney pipe through the roof opening is solved in 2 directions:

- fire protection of the roof truss frame at the pipe aisle;

- waterproofing holes from the penetration of precipitation by those materials that will help isolate the pipe and are most suitable for the type of roofing material and its color.

Conclusion of a pipe through a roofing cake according to all fire safety standards

The separation of the chimney and the multilayer roofing cake (with insulation, hydro- and vapor insulation) is carried out according to all modern standards:

- for double metal pipes, internal insulation with mineral wool is provided;

- a single pipe is wrapped with a finished insulating shell of the required diameter and protected from the outside;

- in masonry, it is important to increase the wall thickness of the order (38-40 cm) and protect the contact surfaces with special plaster.

The box for the outlet of the chimney is constructed from a transverse beam and rafters, observing the distance from the wooden structure to metal chimney not less than 15 cm. The gap between them is filled with basalt cotton wool.

The fire safety regulations indicate that in the contact circumference of the chimney the temperature should not be higher than 50 ° C. The film membranes inside the roofing cake can be made of flammable materials, so a gap and additional insulation with non-combustible mineral wool are necessary between them and the pipe.

The membranes of the roofing pie, dissected at the exit of the pipe, must be carefully dissected and wrapped. Then they are pressed with a crate and fixed on the edges of the box with nails. For complete tightness of the roof, the pipe in this place should be wrapped with a special sealing tape.

When the chimney goes through an unheated attic, and not in a residential attic, the risk of overheating of the roof elements is reduced. Full tightness of the insulation is necessary in any version, but it is better to additionally wrap the pipe with special tape. Proper installation of the internal waterproofing and the outer hood will provide reliable sealing after arranging the thermal insulation of the chimney in the roof opening.

The conclusion of the pipe through the roof

The conclusion of the pipe through the roof Chimney insulation options

In most cases, well-organized chimney insulation on the roof counteracts atmospheric leakage. But there are 2 types of possible leaks:

- from above when the insulating cap is incorrectly installed over roofing materials;

- from below when waterproofing agents are incorrectly laid under the deck.

The simplest way to externally insulate the chimney is to install a finished insulating apron or hood.

Try to cut such a device from a galvanized sheet yourself to eliminate leakage in the old roof, this will save money. With this method, no fitting is needed - all the structural features of the roof and the pipe coming out of it are taken into account.

Products of this type are also available in various materials. It is important to choose an insulating cap (apron) that fits the width of the metal chimney. Or a complete roofing passage is selected, which is acquired together with a sandwich pipe.

Pipe insulation option

Pipe insulation option Any building and roof gradually shrink, therefore, rigid fastening of waterproofing is not always effective. Visually, the integrity of the roof is maintained, and signs of depressurization gradually appear at the joints. Experts recommend reinforcing the insulation in the places where the cap is fastened - with an elastic heat-resistant gasket.

Among the most reliable structures for the passage of the pipe through the roof is a specially made box - by the type of rafter system. Instead of wood, which refers to flammable materials, it can be made of galvanized roofing, but in the same way.

The design of modular chimneys has ready-made thermal insulation, but they differ in configuration. For example, there is a double pipe with a layer of basalt wool or a special ceramic core and an external housing made of concrete. The assembly of modular units is quite simple - a diagram is attached upon purchase.

It is possible to install a gasket made of asbestos, followed by sealing with an asbestos solution. Each new module block is attached above the previous one with the same mixture composition. After installation is complete, the pipe is isolated from leakage in the roof window in any manner described.

A modern roof with corrugated board has its own characteristics - here it is better to make the window for the chimney a little wider. All abutting surfaces are likewise filled with materials with thermally insulating properties. The chimney before wrapping with basalt cotton wool is placed in a steel box. Carefully dissect the film layers of vapor and waterproofing, fix it at the edges of the box. Between it and the pipe it is imperative to make heat-resistant filling.

Roofing

Roofing Next, external waterproofing is carried out - the sealing cap material corresponding to the dimensions of the chimney pipe is put on top, the edge is attached with a clamp to glue. The lower edge is tightly fitted to the roofing material, rigidly fixed with sealant. A steel hood is often included with such a chimney. They are put on round pipes. Installation is recommended when the smoke from the solid fuel boiler at the outlet has a temperature of more than 100 ° C.

If you correctly insulate the chimney pipe, then you will not face dampness and rotten ceiling.

Question: "How to isolate a metal chimney pipe?" ask very often. This has to be done from such destructive factors:

- overheating of the structure;

- leakage in butt joints.

Solving the problem of how to isolate the metal chimney pipe in the bathhouse, it is necessary to put the safety of people a priority.

The main threat in this room is the presence of live fire. Isolation in this case is necessary. Without proper protection, the ceiling easily lights up.

Most often, the bath is built of wood, and as you know, this material is easily flammable. Many mistakenly believe that the upholstery of the ceiling with sheets of metal will be excellent protection, and that no more isolation is necessary.

But, this protection is heated and it will not save from ignition. You can isolate the pipe with red brick, but not every bath design is suitable for this.

The market of modern building materials, to isolate the chimney, provides several products:

- Foloizol. A sauna with such a finish is similar to a thermos design. Heat is not lost, the room quickly warms up and freezes for a long time.

- Thermal insulation. They can be wrapped in a chimney pipe and secured with wire or special metallized tape.

With them, do not worry about isolation. This structure is constructed of several sections, easily inserted one into another. This is suitable even for a bath with a metal stove.

For construction in a traditional Russian bath, red brick is used. It is not affected by heat and holds heat for a long time.

Such a building should fit correctly. Because the duration of the use of the structure depends on the masonry quality indicator.

How to wrap a metal chimney

It is not difficult to decide how to wrap a metal chimney pipe. The building materials market offers many products for this.

IMPORTANT! The most important thing you need to know when performing warming is that you can’t take a coating for it that contains flammable substances.

It is better to isolate with good quality products that comply with fire and building standards. This will create additional security conditions.

Of the proposed options are most often used:

- Fibrous building material;

- Mineral wool;

- Glass wool.

Learn how to insulate a metal chimney

The metal version, and in particular its insulation, deserves special attention. drawing up a construction project.

It is not always possible to isolate an already created scheme without restructuring the roof structure.

If you build a modern design, you can use the finished pipe "sandwich". Such designs are performed quickly, with little cost to specialists.

But, they are not cheap. However, this cost is justified by the long service time and ease of construction.

In them, mineral wool is located between the two blanks. Insulation thus comes out at the highest level.

With the help of insulation, they stop or prevent irreversible chemical reactions that occur under the influence of moisture and fuel decomposition substances.

Failure to take timely measures to warm the chimney pipe can become a basis for violating the integrity of the house due to destruction.

Amplified by the action of acid condensate, slowly, but intensively spoils building materials. Condensation is especially dangerous during the thawing period of a pipe after winter.

Box making

Many people are afraid to make their own metal box to the chimney pipe. But, it does not contain much complexity.

In the manufacture of boxes need the following tools:

- Scissors for metal.

- Galvanized sheet.

- Self-tapping screws.

- Compass.

- Drill.

Further sequence of actions:

- A hole is being prepared. Its edges need to be fixed with support bars. They will create support for the box.

- A pair of parts is cut from a galvanized sheet. At their edges, at a distance of five centimeters, a bend of 90 degrees is made. These p-shaped parts are fixed with self-tapping screws to the prepared holes in the ceiling.

- Two more U-shaped blanks are prepared in the same way, and they are lapped onto already existing sheets. As a result, there is a single frame of the done exit in the ceiling.

- A further part of the action is the bottom for the box. An element is cut out of the same galvanized sheet, corresponding in size to the made opening. In its center, a circle is drawn with a pair of compasses for the entrance of the flue blank.

- 4 fasteners are placed from the central part of the bottom of the box (each of them has a two-centimeter width). Then they are cut out and bent at an angle of 90 degrees. As a result, a base is formed with a hole and 4 strips for fasteners.

- The bottom is attached to the walls. A chimney is inserted through the outlet and secured with a clamp. Empty space is filled with an insulating layer.

According to the proposed instructions, it is not difficult to make a box. If you follow everything exactly, the work will not be difficult even for an inexperienced layman.

Chimney installation

The problem of how to correctly install a chimney from metal pipes is not solved as easily as it seems at first glance. It is very important that it functions as it should.

Otherwise, combustion products will not only damage furniture, but also harm the human body.

Any construction of this type is done according to the following principles:

- Regarding smoke. At the same time, a tee is installed in the network, which removes condensate.

- Regarding condensate. However, this tee is not used.

First stage. This is the choice of the project and the selection of materials. At this stage, it becomes clear what kind of building will be (direct or with transitions and bends).

Second phase. This is an assembly. All butt joints, knees and tees must be securely fastened with clamps.

Third stage. Passing through the roof. Through the roof, the withdrawal takes place with the help of special separation.

She is elected according to the level of the roof slope. Then the place where the workpiece will be held is determined.

The slope angle is regulated by a part of the groove, and its extreme parts are “adjusted” to the ridge. On the walls of the pipe lay insulation.

Fourth final stage. An adjustable apron is attached to the pipe and the pipe grows to the required length. Its edges are closed with a lid - an umbrella. It will protect against atmospheric precipitation.

Chimney mount

In this case, the gaps between the roof and the pipe must be closed with waterproofing. Raise the building above the roof is recommended in accordance with existing rules.

When conducting from the outside of the structure, the problem of how to fix the metal chimney pipe is not acute. Because for this they use a knee, which sets the direction of the vertical position.

For reliability, the chimney is fixed to the wall with special brackets. They can be contained already in the finished kit upon purchase, and it is also not difficult to make them yourself from a metal corner.

When the structure rises to the level of the ridge of the roof and is firmly fixed to the wall, an umbrella is always put on top of it. It protects against clogging with fallen leaves, rainwater and snowfalls.

Transition from a brick chimney to a metal

How to lengthen a brick chimney metal pipe? This question is asked very often.

To extend the brick chimney, you should make a flat steel platform with a pipe. The diameter of the pipe should correspond to the diameter of the workpiece for elongation.

This extension pad must be securely fixed. To do this, take dowels and screws. But, such a mount would not be reliable without sealant.

And now all the lengthening actions are in order:

- On a brick base, it is necessary to mark all the attachment points. These places should not be on a masonry seam. Also, they should not be on the edge of the brick.

- Further, holes for self-tapping screws are drilled in the site, and holes for dowels are made in bricks.

- The pad is placed on.

- After that, the platform is evenly attracted by self-tapping screws along the entire perimeter.

- Further, this transition can be mounted only after the sealant has completely dried.

Now the brick building can be extended to any desired distance with a metal billet.

Some installation rules

- If the outlet for smoke rises above the roof by more than 1.5 meters, then it is recommended to additionally attach it with extensions.

- The length of the pipe from the stove to the head should not exceed 5 meters.

- To clean from condensate, special plugs are mounted.

- Outside the roof, the structure should be withdrawn no less than 1.5 meters.

- When installing a nozzle for exhausting smoke, one must not allow narrowing of its diameter.

- Nearby structures made of combustible materials should not heat up to more than 50 degrees.

- The smoke outlet must be at a safe distance from the wiring.

When deciding how to isolate a metal chimney pipe, everyone makes a decision based on their preferences and financial capabilities.

The main thing in this matter is to do everything in accordance with the norms and requirements, and then the work will please with a quality result.