Stainless steels A2 and A4. Practical application and design features. Steel A2 and A4 steel are the abbreviated names of grades of stainless austenitic (Austenitic) steels. Austenitic steel possesses a number of remarkable properties that have made it very widely used in the national economy. Steels A2 and A4 are non-toxic and resistant to corrosion. They are well exposed to mechanical and heat treatment, as well as welding. Fasteners made of A2 steel and A4 steel are practically non-magnetic, strong and durable. They perfectly retain their properties at high and low temperatures.

Steel A2 has a domestic analogue - stainless steel 08X18H10 and a foreign analogue - stainless steel AISI 304 (in the USA). Assembly units, parts and fasteners made of A2 steel are used in the oil, food, chemical and gas industries; in instrument making and shipbuilding; in construction during the installation of ventilated facades and stained-glass structures, as well as in the manufacture of pumping equipment. Products made of A2 steel retain their strength properties in a wide temperature range: from low (-200 degrees Celsius) to high (+425 degrees Celsius).

Steel A4 is similar in its characteristics to steel A2, but its scope has expanded significantly due to the addition of 2-3% molybdenum, which contributes to its higher resistance to corrosion in environments containing acids, salts and chlorine. Products made of stainless steel grade A4 retain their strength properties at low (up to -60 degrees Celsius) and high (up to +450 degrees Celsius) temperatures. These products are used: in the chemical industry, where they are exposed to aggressive environments; in shipbuilding (fasteners and rigging products) to protect against the damaging effects of sea water; in pools containing chlorinated water. Steel A4, like steel A2, also has a domestic analogue - steel of the 10X17H13M2 type and a foreign analogue - steel AISI 316 (in the USA).

Steel A2 and A4 steel are excellent for the manufacture of fasteners of increased accuracy class A, which are used to create strong and durable critical connections. Bolts and nuts of this class are made, for example, on numerically controlled lathes (CNC). The difference in thread diameters, external for the bolt and internal for the nut, after finishing on the machine does not exceed 0.25 ... 0.3 millimeters. However, the price of parts made from stainless steel will be significantly higher than that of parts made from conventional carbon steel. Strength class for bolts made of stainless austenitic steel grade A2 and steel grade A4, equal to 50, 70 or 80.

High quality stainless steel hardware, mainly made of steels of grades A2 (analogue of steel 12X18H9 in accordance with GOST or AISI 304 in the USA) and A4 (analogue of steel 03X17H14M2 in accordance with GOST or AISI 316 in the USA) are most often generalized into one class of metal products.

Steel grade A2 - austenitic stainless steel. Corrosion-resistant, non-magnetic and non-toxic. Stainless steel hardware made from it are recommended for use in general construction works.

Steel grade A4 - austenitic acid-resistant steel. It differs from the A2 steel grade by the addition of 2-3% molybdenum, which significantly increases its ability to resist corrosion and acids. A4 steel is completely non-magnetic. The A4 fastener is recommended for use in shipbuilding, food industry and is suitable for use in acids and environments containing chlorine.

Steel grades A2 and A4 have a number of important characteristics:

- High degree of resistance to corrosion;

- Strength;

- Hygiene;

- Long service life;

- Aesthetically attractive and presentable appearance;

- Resistance to high and low temperatures from -200 C to +600 C.

They are used in various industries:

- Aviation;

- Building;

- Mechanical engineering;

- Food industry:

- Furniture manufacture;

- Shipbuilding;

- Automotive;

- Khimprom;

- Manufacturing of medical equipment, etc.

Stainless hardware has the following strength classes:

- 50 - soft;

- 70 - riveted;

- 80 - high strength.

The strength class in stainless steel hardware is indicated by a dash after the steel grade. For example: DIN 931 M12x40 A4-80 where

A4 - steel grade;

80 - strength class.

From the OPM warehouse you can purchase stainless steel hardware from A2, A4 steel grades:

Nuts:

Wing nut DIN 315 A.F

Low nut DIN 439 analogue of GOST 5916, 5929

Hex nut DIN 934 analogue of GOST 5915, 5927

Low self-locking nut DIN 985

Cap nut DIN 1587 analogue of GOST 11860

Self-tapping screw with countersunk head and cross recess DIN 7982 analogue of GOST 1145

Screw universal countersunk head and Pz slot

Bar and studs including,

Hairpin with a screwed end 1.25 d long analogue of GOST 22034, 22035

Threaded rod 1-2 meters DIN 976 (former DIN 975)

Other:

Traction rivets DIN 7337

Pins DIN 7

Cotter pin DIN 94 analogue of GOST 397

When selecting stainless steel hardware, use the table "Mechanical properties of connecting elements: austenitic steel grades"

table is being edited

Since chromium-nickel steels cannot be hardened, an increased yield strength is achieved only by work hardening under a cold forming press. Therefore, when selecting set screws, use the table

Stainless steel is the most widely used material from which equipment for the production, storage and transportation of food products is made. This is due to the high requirements that it must meet in terms of hygiene, toxicity, etc.

Wine production environments are very aggressive towards carbon steels... The aggressiveness of various wines is determined by the content of sugars, organic acids, sulfurous anhydride and alcohol. These rates vary significantly depending on the type of wine. Thus, table (dry) wines do not contain sugars, but only 9-14% vol. alcohol, fortified wines contain 8 - 10% vol. Sugars and 16 - 20% vol. alcohol, sweet dessert wines - 8-20% vol. Sugars and more than 13% vol. alcohol, semi-sweet table wines - 3 - 7% vol. Sugars and 7 - 12% vol. alcohol. The mass concentration of titratable acids is in the required GOST range (3-8 g / dm3). Sulfurous anhydride is traditionally used in wort clarification. The permissible concentration (MPC) of sulfurous anhydride in wines, as a rule, is not more than 150 - 400 mg / l.

In alcohol and alcoholic beverage industries, technological media are corrosive. They may contain unfermented sugar, organic acids, esters, fusel oils, aldehydes, etc. These media include mash (grain, molasses, cane), rectified alcohol, raw alcohol, stillage, as well as vodka, various liqueurs , tinctures and low alcohol drinks.

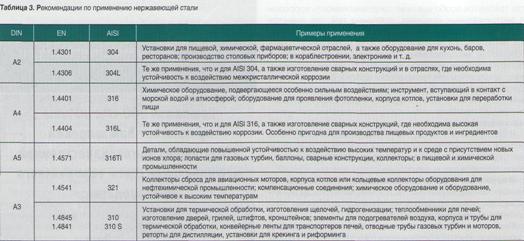

CHARACTERISTICS OF ALLOYS AND THEIR APPLICATION

The characteristics of various stainless steel alloys are given in table. 1 and 2.

Some Russian suppliers persistently convince consumers that AISI 430 (12X17) pipe products can also be used in pipelines for the food industry. This is not true, since clause 4 of DIN 11850 ("Materials") unambiguously indicates that in the food industry only the following steels can be used as standard: AISI 304 (1.4301), AISI 304L (1.4307), AISI 316L (1.4404).

This group of stainless steels is the most widely used and includes grades 304 and 316. These materials are ideal for use in food processing, milk, wine and alcoholic beverage industry, brewing, pharmaceutical, chemical and petrochemical industries. Grade 304 stainless steels contain approximately 18% chromium and 10% nickel and exhibit excellent corrosion resistance. Where particularly high corrosion resistance is required under extreme conditions, especially where chlorides are present, grade 316 steels are used containing about 17% chromium, 12% nickel and 2.2% molybdenum. Steel 12Kh18N10T is acid-resistant, not subject to intercrystalline corrosion, heat-resistant up to 600 ° C. It is used to make equipment for milk processing, cans, flasks, fermentation vats, barrels, storage equipment for wineries and distilleries, as well as utensils for cooking and equipment for kitchens and canneries.

Unlike other stainless steels, austenitic grades are non-magnetic, and as a result, magnetic particles do not adhere to the walls of the system, which could otherwise cause clogging.

Ferritic stainless steels (much softer than martensitic, due to the low carbon content; also have magnetic properties, denoted by the initial letter F).

Ferritic stainless steels are less corrosion resistant than austenitic 304 and 316 and are used where the requirements are less demanding. Ferritic steels contain 11.5-16.5% chromium and less than 0.5% nickel. Steels in this group are magnetic and will cause adhesion of magnetic particles, which can lead to contamination problems. Ferritic steels are unsuitable for the manufacture of drainage products.

Martensitic stainless steels(much harder than austenitic steels and can be magnetic; more susceptible to corrosion, indicated by an initial C).

Martensitic steels are magnetic and are characterized by the highest strength in the group of stainless steels, while at the same time they have the least resistance to corrosion. They can be thermally hardened and are mainly used for the manufacture of knife tools.

The types of steels of the most common - austenitic - group are indicated by an additional number, which indicates the chemical composition and applicability within this group:

... A1- are used, as a rule, in mechanical and movable assemblies. Due to the high sulfur content, steels of this type are less able to resist corrosion than other types;

... A2 - non-toxic, non-magnetic, non-hardenable, corrosion-resistant steels. Easily weldable and non-brittle. May show magnetic properties as a result of machining (washers and some types of screws). This is the most common group of stainless steels. Fasteners and products made of A2 steels are not suitable for use in acids and environments containing chlorine (such as swimming pools and salt water). They are suitable for temperatures down to -200 ° C. The closest analogues are AISI 304 and AISI 304L with an even lower carbon content;

... A3- similar in properties to A2 steels and additionally stabilized with titanium, niobium or tantalum. This increases their resistance to corrosion at high temperatures;

... A4- similar to steel A2, but with the addition of 2 - 3% molybdenum. This makes them much more capable of resisting corrosion and acid attack. A4 fasteners and rigging are recommended for use in shipbuilding. Suitable for temperatures down to -60 ° C. The closest analogues are AISI 316 and AISI 316L with low carbon content;

... A5- has the properties of A4 steels and is additionally stabilized with titanium, niobium or tantalum, like A3, but with a different content of alloying additives. This also increases its resistance to high temperatures.

The choice of stainless steel grade for each application is very important. It should be remembered that even 316 stainless steels are not protected against all types of chemical attack, for example from use with reducing solutions such as hydrochloric and oxalic acids, especially in a concentrated and / or heated state.

"Distillery and winemaking" No. 10 (106), October 2008

A. S. Boguslavsky

At the dawn of its history, stainless steel with its corrosion-resistant properties gave rise to many myths among people, and products made of it were considered miraculous, since they were timeless. What this alloy is today, we will discuss in the article.

1

Today stainless steels are a fairly large set of alloys with different properties, which are described by numerous GOSTs and TUs. But they have one common property - resistance to moisture and oxygen, the main enemies of iron-containing materials. Achieve such "vitality" allows a special chemical composition. All types of this alloy contain more than 10% chromium in their composition, which easily triggers the passivation process on the steel surface.

Stainless steel pipes

The inactivity of the stainless steel surface is explained by the thinnest layer of oxide film, which is formed by chromium under the influence of oxygen. This protects the product from any other interaction, including water, the main activator. Moreover, the beauty of this composition is that even if the integrity of the surface is violated, such a layer very quickly reappears. For example, if a chip or deep scratch is formed, then the chromium, which is evenly present throughout the entire volume of steel, will react with oxygen again and create a protective film. This kind of healing effect.

But stainless steels also have a weak point due to their unusual properties. In oxygen-free environments or environments with a low content of this oxidizing agent, the chromium oxide layer will form slowly and unevenly, which will necessarily be reflected by the appearance of foci of corrosion... Also, a simple violation of production technology can become the cause of material damage. Then the corrosion is called crevice. It can also be of an electrochemical nature, so it is also not necessary to discount the danger of interaction with other metals and salty environments (for example, sea water).

Despite the enviable properties, stainless steels can change their quality depending on the alloying elements. For example, sulfur can strengthen the alloy, but to the detriment of anti-corrosion properties, and nickel will increase the resistance to acidic environments. Additives from Mn (manganese), Mo (molybdenum), Cu (copper) and other metals of this family endow steel with the same properties. More exotic metals like Ti (titanium), Nb (niobium) or Ta (tantalum) will make the alloy more heat resistant.

2

In terms of structure, chromium stainless steels are divided into 5 types, 3 types are of interest to a wide user - ferritic (F), martensitic (C) and austenitic (A). The first type contains little carbon, so it is softer and can have magnetic properties. The second is the hardest, less resistant to corrosion, and can also act as a magnetic material. Suitable for tableware, cutting tools and in some areas of mechanical engineering. Austenint is considered the most popular. It is a non-magnetic alloy with a high content of chromium (almost 20%) and nickel (up to 15%), resistant to corrosion. Such stainless steel is machinable and used in a wide variety of industrial applications and for the manufacture of fasteners.

Stainless steel alloys

According to the national GOST, ferritic stainless steel is often designated 12X17, this is a heat-resistant variety, but poorly welded. Therefore, mainly solid-rolled products, pipes or rods are made from it, and there is also a sheet form of release. For each product, you can find the corresponding GOST with quality requirements. To access all the characteristics of stainless steels, you can use GOST 5632-72. All types of alloy with a brief description of the application, chemical composition and physical properties can be found in this one document. For more detailed data and special instructions, it is better to look at individual GOSTs, which almost every brand of stainless steel has. Martensitic types of anti-corrosion steel are recognized leaders in strength due to the most stable structure. They also have a kind of metallic memory from a technological point of view. Quite often, such steel is marked as heat-resistant.

As you can see from GOST 5632–72, it is represented most widely, it is a very diverse list of alloys both in composition and in properties, but all of them are heat-resistant and very resistant to corrosion. These are the so-called 300 series stainless steel. This steel is versatile, which is why it is so popular in the market. We will discuss its types in a separate paragraph.

3

Steel A1 is characterized by a high sulfur content, which leaves some mark on its resistance to corrosion, although it is very heat-resistant, sometimes the threshold reaches 1000–1100 ° C. True, it is important to monitor the acidity of the environment, the atmosphere should be reducing, and there should not be more than 2 g / 2 m of sulfur. Elements made of such steel are used in the manufacture of alkalis or hydrogenation, naturally, all installations for thermal operations are made of them (furnaces, branch pipes of motors and turbines, cracking units, reforming machines). Also, doors, pins and brackets for ovens are made of this alloy.

A4 steel items

A2 steel is easy to weld without losing strength. Like all the species under discussion, it resists corrosion well, does not contain toxins, and does not exhibit magnetic properties. Although the last statement can be corrected if the product is properly processed. This is how magnetized washers and screws are obtained. This is a fairly common grade of steel, but it is not acid-resistant, therefore, using fasteners made of this alloy in a pool where there is a lot of chlorine or salt sea water will not work. According to GOST 5632-72, products made of A2 steel do not lose strength at low temperatures down to -200 ° C.

Within this type, there are several analogues with different, but significantly low carbon content. These steels are resistant to intercrystalline corrosion (hidden from the human eye and detected already at later stages), which is why they are leaders in those industries where this property is important. Mainly you will find A2 products in light, chemical and pharmaceutical and plastics industries. Also, GOST 5632-72 allows the equipment of catering units with steel materials, for example, kitchens, restaurants, bars.

Steel A3 is very similar in characteristics to A2, but has useful alloying additives (Ti, Nb, Ta), because of this, it is more heat-resistant than the previous type. Even at high temperatures, the product is capable of not losing quality and not being covered with corrosive corrosion. This alloy withstands decent quality up to 800 ° C. Therefore, it is often used for chemical equipment, in boiler casings, as compensation compounds.

A4 steel is the most acid resistant. Its composition differs slightly from A2, mainly by the presence of small amounts of molybdenum (about 2–3%). But even this small amount makes it less prone to intercrystalline corrosion, even in aggressive environments. A4 products can maintain their properties at a decent level - down to -60 ° C in the negative range and up to 450 ° C in the positive. Under this marking, there are also various combinations of steels in terms of chemical composition, more detailed proportions that such an acid-resistant grade can have can be found in GOST 5632-72. Alloy A4 is the main contender for use in the food and chemical industries. An instrument is made from it, which will have contact with sea water. You can also find quite often all kinds of hardware made of A4 steel. The reason for their popularity is their versatility, they are not afraid of water or acids and are quite durable.

Under the A5 brand, a certain averaged version between A4 and A3 was assembled, so the properties are the same in demand. This steel is heat-resistant and can resist in aggressive chemical environments, that is, it can also act as acid-resistant.

Special chemical processes inside the crystal lattice create a strong immunity to intercrystalline corrosion. The scope of application of products from such steel is similar to the description of A4. Marking is expressed according to the DIN standard, but almost every country with a large steel industry has its own standard, summary tables can be found on the vast network. Also, in each type of stainless alloy there is a more fractional division - steels are marked based on the composition and proportions of the elements included in it. This is clearly seen in GOST 5632-72, which lists a huge number of brands and their analogues.

4

Since the set of stainless alloys is huge, and it is rather difficult to navigate in them, you need to know some special markings. For example, high-strength 16X16N3MAD is most often used in the aviation industry. It is capable of not suffering from corrosion and can do so under harsh environmental conditions and element loads. This high-strength grade is also used for cables for bridges and building structures. In view of the responsibility imposed on products made of this material, all rolled metal products have a lot of requirements set forth in numerous OST, GOST and TU.

Steel 16KH16N3MAD

Acid-resistant steel is also a very important component of industrial and not only installations, and mistakes in its choice can also be very expensive. And the danger here is that chemicals are capable of destroying the alloy secretly, at the level of the crystal lattice, and will open to the human eye even when an accident occurs. The most typical representative of such steels is 10Х17Н13М2Т. This acid-resistant brand has several close analogs - 15Х25Т, 08Х22Н6М2Т.

The scope of stainless steel fasteners is very extensive. To technological installations of the chemical, pharmaceutical, food industries, increased requirements are imposed on work under conditions of exposure to chemically aggressive substances, hygiene, durability. Many elements of these machines and mechanisms are made of high-alloy, corrosion-resistant stainless steels. Of course, these elements include a variety of stainless steel fasteners.

Types of stainless steel fasteners

Today, in the trade network and representatives of manufacturing plants, you can choose stainless steel hardware of any kind. Depending on your needs, the following types of stainless steel fasteners are available:

- with hex head, full and partial threads;

- swing bolts;

- eye bolts;

- mounting, with semicircular, countersunk and hexagonal heads, with straight, cross-shaped recesses and hexagonal holes;

- flat washers, oblique, with a rectangular hole and Grover's washers;

- retaining rings and washers;

- cylindrical and conical pins;

- single- and seven-strand cables;

- short link chains;

- with semicircular, countersunk and hexagonal heads, with straight and cross recess.

The range of stainless steel hardware allows you to choose the required type of fastener depending on the specific conditions of its operation.

Fasteners are made of stainless steel A2, A4 or their domestic counterparts - 12X18H9T, 10X17H14M2T. A2 stainless steel is not subject to hardening, retains its properties up to -200 ° C. Hardware from this stainless steel is easily welded without increasing fragility. A2 stainless steel hardware and fasteners are not used in acidic and chlorine-containing environments. Steel A4 differs from A2 by a 2-3% increase in molybdenum content, which makes it more resistant to acids. The main areas of application of A4 steel are shipbuilding, the production of hardware and products for rigging.

Benefits of stainless steel fasteners

The advantages of stainless steel hardware include the following:

- non-toxicity, which makes it possible to use it in devices for the food and pharmaceutical industries, as well as for the production of medical equipment and equipment for cooking;

- non-magnetic, which allows the use of stainless steel fasteners in instrument making;

- preservation of strength characteristics in a wide temperature range;

- the ability to manufacture interior elements that fit into the High-tech style.

All this makes stainless steel hardware in demand in the fasteners market.