| Structural carbon steel of ordinary quality | ||||

Depending on the carbon content, the following steels are distinguished:

Mild steels containing up to 0.25% carbon

Medium carbon steels containing 0.25 to 0.6% carbon

High carbon steels containing 0.6 to 2% carbon

Low-carbon steels are those that do not contain alloying components (except carbon). Manganese and silicon are present in low-carbon steels, but they are not considered alloying components if the manganese content does not exceed 1% and silicon — 0.8%.

Most welded structures are made of low-carbon steels produced in the form of sheets and shaped sections - a corner, channels, I-beams, etc.

The steels are divided: by chemical composition - into carbon and alloyed; by the method of production - for open-hearth, Bessemer, converter, electric steel; as intended - for structural, tool and steel with special properties.

Carbon steel of ordinary quality. Such steel, manufactured in open-hearth furnaces, in converters with oxygen purging from above, and in Bessemer converters, is supplied in accordance with GOST 380-60.

Depending on the purpose and guaranteed indicators, steel is divided into three groups:

group A - supplied by mechanical properties;

group B - supplied by chemical composition;

group B - supplied by mechanical properties with individual requirements for chemical composition.

The following grades are installed for steel of group A: Art. 0, Art. 1, Art. 2, Art. 3, Art. 4, Art. 5, Art. 6, Art. 7. If the steel is boiling, then the index kp is put in the designation of the brand, if ps is semi-quiet (for example, St. Zkp, St. 4ps, etc.), the absence of an index means that the steel is calm.

Boiling is called steel, which is not fully deoxidized in the furnace and contains a certain amount of iron oxide, which causes continued boiling of the steel in the mold. Smelting boiling steel is cheaper, but such steel contains dissolved gases, such as nitrogen, sometimes cracks occur during its welding.

If the steel in the furnace is completely deoxidized, then it does not contain iron oxide and, being poured into molds, does not boil. Such steel is called calm. It does not contain gases, but its smelting is more expensive. For critical welded structures, it is preferable to use mild steel.

Half-soaked steel is deoxidized to a greater extent than boiling, but less than calm. This steel hardens in molds without boiling, but with the release of gases; it contains less (compared to boiling) gas bubbles, which are completely welded in the process of subsequent rolling. Semi-quiet steel is mainly used as structural.

Group B steel is made in open-hearth, Bessemer and converter methods. Group B open-hearth steel in the designation of the brand has the letter M, Bessemer's - the letter B, converter - the letter K (for example, MSt. 2kp, BSt. 3, Kst. Zps). Bessemerovskaya steel of group B is produced only by grade BST. Oh bst. 3, BS 4, BS 5, BS 6.

Group B steel is made in open-hearth and converter processes. Open-hearth steel of group B is made of grades: Navy. 2, Naval Forces. 3, Naval Forces. 4, Naval Forces. 5. Converter steel B is made of the same grades, but the letter K is put in its designation (for example, VKSt. 2, VKSt. 3, etc.). Steel of all groups with serial numbers 1, 2, 3, and 4 is made of steel, ps, and steel; with steel numbers 5, 6, and 7, only ps and cn are produced.

Art. O - unmarked building, in which the content of carbon and other elements can vary widely. This steel may contain increased amounts of sulfur and phosphorus. Steel Art. About apply only in constructions of non-essential purpose.

Steel grade Navy. 3 contains carbon 0.14–0.22% and has the following mechanical properties: temporary resistance 38–47 kgf / mm 2, yield strength 22–24 kgf / mm 2, elongation not less than 21%, impact strength across rolling - not less than 7 kgf-m / \u200b\u200bcm 2.

Quality carbon structural steels. Such steels are used for the manufacture of critical welded structures. They are produced according to GOST 1050-60, which guarantees mechanical properties and chemical composition. High-quality carbon steels according to GOST 1050-60 are marked with numbers indicating the average carbon content in hundredths of a percent. For example, brands 05; 08; fifteen; 20, etc., mean that steel contains an average of 0.05 carbon, respectively; 0.08; 0.15; 0.20%. Steel according to GOST 1050-60 produce two groups:

group I — with a normal manganese content (0.25-0.80%);

group II - with a high content of manganese (0.70-1.20%).

In the steel grade of group II, the letter G is placed, indicating that the steel has a high content of manganese.

Of the low-carbon steels for especially critical welded structures, the most suitable steel is grade M16C (GOST 6713-53), containing not more than 0.20% carbon, 0.12-0.25% silicon, 0.4-0.7% manganese, not more than 0.045% sulfur and not more than 0.040% phosphorus.

For welding low carbon steels, electrodes of types E42 and E42A are used in accordance with GOST 9467-60 with rutile, calcium fluoride, ore-acid and organic coatings. The type of current, polarity and current value are selected in accordance with the nature of the coating, the thickness of the metal, the type of weld and the diameter of the electrode. In addition to those indicated in table. 5 grades of electrodes; for welding low carbon steels, electrodes of other grades are also widely used, for example, ANO-3 with rutile coating and iron powder; ECR with a coating containing cellulose and insensitive to high moisture content and many other brands of electrodes manufactured by the industry.

When welding fillet welds thick metal and the first layer of a multilayer weld, when the cooling rate is high enough, it is recommended to use preheating of the base metal to 120-150 ° C to prevent the appearance of quenching structures and crystallization cracks. To fix defective sections of the weld, weld seams of normal (full) section, at least 100 mm long, should be used, since at high cooling rates the ductility of the metal of the under-weld of a small section decreases, which will lead to cracking. It is useful to heat this section of the main seam to 150 ° C before applying the weld seam. The presence of incompletely welded tacks and welding of defects with surface (“fluent”) seams greatly reduces the ductility of the weld metal in this place and reduces the reliability of the welded structure. Subsequent local leave or normalization of the brewed area in this case is less effective than preheating.

Medium carbon steels (C from 0.26 to 0.45%) are welded with a wire with a low carbon content (C from 0.08 to 0.1%), seams with edge cutting are used, a small current; while trying to get a shallow penetration in order to reduce the proportion of the base metal in the weld metal. These measures reduce the carbon content in the weld metal and prevent the appearance of crystallization cracks. Preliminary and concurrent heating is also used when welding to a temperature of 250-300 ° C. High-temperature heating is harmful, as it causes cracks due to an increase in the penetration depth of the base metal and the resulting increase in the carbon content in the weld metal. The best results are obtained by direct current welding of direct polarity. High resistance of the weld metal against crystallization cracks and the necessary strength welded joint provides the use of electrodes UONI-13/55 and UONI-13/45. In order to avoid the formation of brittle and low plastic quenching structures in the heat-affected zone, it is useful to slow down the cooling of the product after welding. In some cases, it is necessary to resort to subsequent heat treatment (quenching with tempering).

Of high-carbon steels (C\u003e 0.46%), as a rule, welded structures are not manufactured. The need for their welding may arise during repair work, surfacing. In this case, the same methods of welding and surfacing are used as for other low-weldable steels (preliminary and subsequent heat treatment, preliminary and concurrent heating, the corresponding electrode grades and welding modes).

| Short notation: | ||||

| σ in | - temporary tensile strength (tensile strength), MPa |

ε | - relative sediment when the first crack appears,% | |

| σ 0.05 | - elastic limit, MPa |

J to | - torsional strength, maximum shear stress, MPa |

|

| σ 0.2 | - conditional yield strength, MPa |

σ out | - ultimate strength in bending, MPa | |

| δ 5,δ 4,δ 10 | - elongation after rupture,% |

σ -1 | - endurance limit during bending test with a symmetric loading cycle, MPa | |

| σ cr 0.05 and σ cr | - yield strength under compression, MPa |

J -1 | - endurance limit during torsion test with a symmetric loading cycle, MPa | |

| ν | - relative shift,% |

n | - number of loading cycles | |

| s in | - short-term strength, MPa | R and ρ | - electrical resistivity, Ohm · m | |

| ψ | - relative narrowing,% |

E | - normal elastic modulus, GPa | |

| KCU and Kcv | - impact strength, determined on a sample with concentrators, respectively, of the form U and V, J / cm 2 | T | - temperature at which the properties are obtained, Grad | |

| s T | - proportionality limit (yield strength for permanent deformation), MPa | l and λ | - thermal conductivity coefficient (heat capacity of the material), W / (m · ° С) | |

| HB | - Brinell hardness |

C | - specific heat of the material (range 20 o - T), [J / (kg · deg)] | |

| Hv |

- Vickers hardness | p n and r | - density kg / m 3 | |

| HRC e |

- Rockwell hardness, scale C |

and | - coefficient of temperature (linear) expansion (range 20 o - T), 1 / ° С | |

| HRB | - Rockwell hardness, scale B |

σ t T | - ultimate strength, MPa | |

| Hsd |

- Shore hardness | G | - torsional shear modulus, GPa | |

Steel classification

STRUCTURAL STEELS

Currently, steel is the main metal material of the industry. A wide variety of chemical composition of steels and types of their processing allows to obtain various properties and satisfy the needs of many branches of technology. Currently, more than 2000 grades of steel are smelted annually in the world.

There are several classifications that make it possible to systematize steel, which simplifies the search for steel of the desired grade, taking into account its properties. Steel is classified by chemical composition, quality, degree of deoxidation, structure, purpose, etc.

The chemical composition of the steel is divided into carbon and alloy. In terms of carbon content, they are conditionally divided into low-carbon (C ≤ 0.25%, medium-carbon (0.3 ... 0.6% C) and high-carbon (≥0.7% C).

Depending on the content of alloying elements, alloyed steels are divided into low alloyed steels containing less than 2.5% alloying elements; medium-alloyed - 2.5 - 10% of alloying elements; highly alloyed - more than 10% of alloying elements.

According to the predominant alloying element, alloyed steels are divided into chromium, manganese, chromium-nickel-molybdenum, chromium-silicon-manganese-nickel, etc. Due to the fact that alloyed with several elements are more widely used, this classification is cumbersome.

By quality, steels are classified into ordinary quality steel, high-quality, high-quality.

Classification by quality. Under the quality of steel is understood the totality of properties determined by the metallurgical process of its production. The homogeneity of the chemical composition, structure and properties largely depends on the content of harmful impurities - sulfur and phosphorus and gases (О 2, N 2, Н 2), therefore their content standards are the main indicators for the separation of steel by quality.

The quality distinguish steel:

Of ordinary quality (carbon), S≤0.05%, P≤0.04%;

Qualitative (carbon and alloyed) S≤0.04%, P≤0.035%;

High quality (carbon and alloyed) S≤0.025%, P≤0.025%;

Particularly high-quality (alloyed) S≤0.015%, P≤0.015%.

According to the degree of deoxidation, steel (carbon) is classified into calm, boiling and semi-calm. Deoxidation is the process of removing oxygen from a liquid metal to prevent brittle fracture of steel during hot deformation.

Calm steels are deoxidized with manganese, silicon, and aluminum. They contain little oxygen and harden quietly without gas evolution. Boiling steels are deoxidized only with manganese. When they solidify, the release of CO bubbles gives the impression of boiling steel. Semi-quiet steels are deoxidized with manganese and aluminum and occupy an intermediate position according to the degree of deoxidation. Alloy steels melt only quiet.

The structural classification for carbon steels (in the annealed state) is given in Chapter 1, and alloyed (in the annealed and normalized states) in sections 3 of this chapter.

According to the purpose (application), they became united into groups: structural, tool and with special properties. This classification is more meaningful than the previously considered classifications. It characterizes steel to a greater extent, therefore, more attention is paid to its consideration.

Structural steels are used in engineering and construction for the manufacture of machine parts, structures and structures. They can be carbon and alloy. The carbon content in these steels does not exceed 0.6%. However, in some cases it can reach 1%.

Details of modern machines and structures operate under conditions of high dynamic loads, high stress concentrations and low temperatures. Therefore, structural steels, in addition to the high mechanical properties determined during standard tests (σ in - temporary resistance, σ 0.2 - yield strength, δ - elongation, ψ - relative narrowing, HB - hardness) should have high structural strength, t. e. strength, which is manifested in the conditions of their real application.

Structural steels should have good technological properties: they can be well processed by pressure (rolling, forging, stamping, etc.), cutting, and have high hardenability. Building structural steels should be well welded by all types of welding.

Structural steels are supplied in the form of blanks and hot-rolled, calibrated and polished steel, in the form of sheets, strips, shaped profiles, etc.

Carbon Structural Steels (general purpose steel). Carbon steels of ordinary quality are smelted in oxygen converters, open-hearth furnaces and electric furnaces. Steel is widely used in construction. A number of steel grades are also assigned to engineering parts. Steel is made of hot-rolled - high-grade, shaped, plate, sheet, broadband (universal) - and cold-rolled - sheet. Pipes, forgings and stampings, tape, wire, etc. are made of steel.

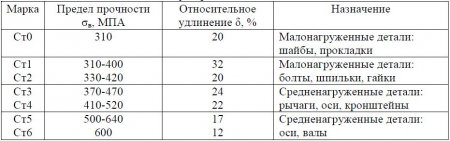

Steel of ordinary quality (GOST 380-94) is made of the following grades: St0, St1, St2, St3, St4, St5, St6. In the marking of steels, the letters St indicate "Steel", the numbers indicate the conditional number of the grade depending on the chemical composition. With an increase in the grade number, with the exception of the St0 grade, the amount of carbon in steels increases. Information on the quantitative chemical composition (including the carbon content, the steel grade does not contain).

Steel of ordinary quality contains, in comparison with other steels, an increased sulfur content of up to 0.05%, phosphorus up to 0.04%, and in steel grade St0: sulfur no more than 0.06%, phosphorus no more than 0.07 %

Steel with grades 1, 2, 3, 4 is made of boiling (cp), semi-calm (ps) and calm (cn), with numbers 5 and 6 of semi-calm and calm. Steel grade St0 according to the degree of deoxidation is not shared. The degree of deoxidation is indicated by the letters kp, ps, cn given at the end of the steel name. For example: St1kp, St2ps, St5sp, etc.

Steel grades St 3ps, St 3sp and St 5ps are made with a high content of manganese. In the designation of these steel grades put the letter G. St 3GPS, St 3GSP, St 5GPS.

Mild steels (deoxidized Mn, Si, Al) contain a reduced amount of oxygen and various oxides. The silicon content is 0.15-0.30%, however, even in these relatively small quantities, silicon increases the yield strength and reduces ductility.

Boiling steels (deoxidized only Mn) contain silicon only as an impurity (≤ 0.05%). Compared to calm and semi-quiet steels, boiling steels have the same tensile strength, but have higher ductility and are well subjected to cold working (rolling, drawing, etc.). Boiling steels are cheaper because the waste in their production is minimal. Since the ductility of steels also depends on the carbon content, its amount in boiling steels is not more than 0.25%.

Semi-quiet steels (deoxidized Mn and Al) contain silicon up to 0.15%. In composition and properties, they occupy an intermediate position. Semi-quiet steels are used, in particular, for cold extrusion of bolts and other parts.

The chemical composition of steels of ordinary quality corresponds to GOST 380-94. This standard complies with international standards ISO 630-80 “Structural steel. Plates, wide chamfers, bars and profiles "and ISO 1052-82" Structural steel for general purposes ", in terms of requirements for the chemical composition of steels.

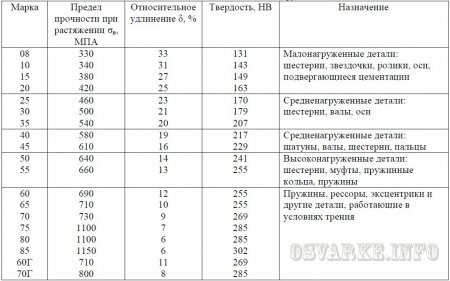

Quality carbon steels (steel for general engineering purposes). Steel is smelted in open-hearth and electric furnaces in compliance with more stringent requirements for the composition of the mixture, the processes of melting and casting. They are subject to higher requirements in terms of chemical composition: the sulfur content should not exceed 0.04%, phosphorus 0.035-0.04% (depending on grade), steel should also have less non-metallic inclusions than ordinary steel.

Carbon quality steels in accordance with GOST 1055-88 are marked with double digits, which show the average carbon content in hundredths of a percent. For example: 05, 08, ..., 15, ..., 45, ..., 60 (respectively 0.05, 0.08, ..., 0.15, ..., 0.45, ..., 0.60% C).

Low carbon steels with a carbon content of up to 0.2% can be boiling, semi-calm and calm. Boiling steel has the letters kp at the end of the marking, semi-calm - ps. For mild steels, letters are not added at the end of their names, for example: 08kp, 10ps, 18kp, 20, 25, 30, 35, etc. The chemical composition of high-quality carbon structural steels complies with GOST 1050-88.

Quality steels are divided into subgroups. Low-carbon 05kp, 08kp, 08, 10kp, 10sp, 10, 11kp have low strength and high ductility. These steels without heat treatment are used for lightly loaded parts (gaskets, washers, tractor hoods, coils), elements of welded structures, etc. Steel is well deformed in the cold state. Sheet cold-rolled low-carbon steel is used for cold stamping of products. The stamping became worse the more carbon in it. Silicon, increasing the yield strength, reduces the formability, especially the ability of steel to accept hoods; therefore, cold-rolled semi-quiet and boiling 08ps, 08kp steels are more widely used for cold stamping.

Steel 15, 15kp, 15ps, 18kp, 20kp, 20ps, 20, 25 are used without heat treatment or in a normalized form. Steel comes in the form of rolled products, forgings, pipes, sheets, tape and wire, they are less ductile and slightly worse deformed in the cold state. Steel is well welded and machined. These steels are used for cemented parts that work for wear and do not experience high loads (for example, cam rollers, levers, axles, bushings, spindles, forks and gearshift rollers, spring fingers and many other parts of automotive, agricultural and general mechanical engineering).

Medium carbon steels 30, 35, 40, 45, 50 are used after normalization, improvement and surface hardening for a wide variety of parts in all engineering industries (camshafts, spindles, friction discs, rods, traverses, rams, etc.). These steels in a normalized state, in comparison with low-carbon ones, have higher strength with lower ductility. Steel in the annealed condition is quite well processed by cutting. The hardenability of steels is small, so they should be used for the manufacture of small parts or large sizes that do not require through hardenability.

Steel grades 50, 55, 60 are used after various kinds heat treatment - normalization of improvement, hardening with low tempering, hardening of high-frequency alloys, etc., which significantly increase the operational and strength properties of parts (gear wheels, spindles, heavily loaded shafts, clutches, rolling rolls, wheels and bandages for rolling stock of railways, clutch discs.

CHAPTER IV. CARBON AND ALLOYED. STEEL

§ 14. CARBON STRUCTURAL STEELS

Carbon steels are divided into three main groups: carbon steels of ordinary quality, high-quality carbon steels and carbon steels for special purposes (automatic, boiler, etc.).

Carbon steel of ordinary quality (GOST 380-71). These most widespread steels are delivered in the form of rolled products in a normalized state and are used in mechanical engineering, construction and in other sectors of the national economy.

Carbon steels of ordinary quality are denoted by the letters St and numbers from 0 to 6. The numbers are the conditional number of the brand. The higher the number, the higher the carbon content, higher strength and lower ductility.

Depending on the purpose and guaranteed properties, carbon steels of ordinary quality are supplied in three groups: A, B, C (Table 1). The indices to the right of the brand number mean: kn - boiling, ps - semi-quiet, cn - calm steel. Between the index and the brand number may be the letter G, which means an increased content of manganese. In the designations of the grades to the left of the letters St the groups (B and C) of steel are indicated.

According to the requirements for standardized indicators (chemical composition and mechanical properties), ordinary steel is divided into categories. The steel category is designated by the corresponding number to the right of the deoxidation index, for example, St6GPSZ means: steel of group A, grade St6, with a high content of manganese, semi-calm, third category. In the case of ordering steel without indicating the degree of deoxidation, but of a certain category, the latter is written after the brand number through a dash, for example, St4-3. Steel of the first category is written without indicating the number of the latter, for example, St4ps.

1. Carbon steels of ordinary quality

The chemical composition of group A steels is not regulated, but their mechanical properties are guaranteed (Table 2). The steels of this group are usually used for parts that are not subjected to hot processing during the manufacturing process (welding, forging, etc.).

Group B steel is supplied in chemical composition and is used for parts that undergo heat treatment and hot pressure processing (stamping, forging) during the manufacturing process. The mechanical properties of the steel of group B do not guarantee.

2. Mechanical properties of carbon steel of ordinary quality

Group B steel is supplied in terms of mechanical properties corresponding to standards for group A steel and chemical composition corresponding to standards for group B steel. Group B steel is used mainly for welded structures.

High-quality structural carbon steel (GOST 1050-74). They differ from steels of ordinary quality with a lower content of sulfur, phosphorus and other harmful impurities, narrower limits of the carbon content in each grade and, in most cases, a higher content of silicon (Si) and manganese (Mn).

Steel is marked with double digits, which indicate the carbon content in hundredths of a percent, and are supplied with guaranteed indicators of chemical composition and mechanical properties (Table 3). According to the degree of deoxidation, steel is divided into boiling (cp), semi-calm (ps), calm (without specifying an index). The letter G in steel grades indicates an increased content of manganese (up to 1%).

High-quality carbon steel is supplied by rolled, forged, calibrated, round with a special surface finish (silver).

Special carbon steels. This group includes steels (GOST1414-75) with good and increased machinability by cutting ( automatic steel) They are mainly intended for the manufacture of parts of mass production. When such steels are processed on automatic machines, short and small chips are formed, the consumption of the cutting tool is reduced, and the roughness of the machined surfaces is reduced.

3. Mechanical properties of high-quality structural steel

Automatic steels with a high content of sulfur and phosphorus have good workability. Machinability by cutting is also improved by introducing technological additives of selenium, lead, and tellurium into steel.

Automated steels are marked with the letter A and numbers showing the average carbon content in hundredths of a percent. The following grades of automatic steel are used: A12, A20, AZO, A40G. Non-responsible parts are made from A12 steel, and more responsible parts working at significant voltages and high pressures are made of steel of other grades. The assortment of automatic steel provides for the production of long products in the form of bars of round, square and hexagonal sections. These steels are not used for the manufacture of welded structures.

Sheet steel (

Dear visitor, you read the article "Carbon Structural Steels", which is published in the category "Materials Science". If you liked or found this article useful, please share it with your friends and acquaintances.

Earn on your knowledge. Answer questions and get paid for it!

November 2, 2011 | Views: 39965 |

Page 1

High-quality carbon structural steel is manufactured in accordance with GOST 1050 - 74 in the form of rolled products and forgings. It is divided into two groups: group I - with normal and group II - with a high content of manganese. Samples of steel produced are subjected to mechanical tests. Carbon steel of ordinary quality in industrial fittings it is used at a temperature of the working medium up to 425 C, and high-quality carbon steel (GOST 1050 - 74) - up to 455 C. In valves for nuclear power plants, carbon steel of ordinary quality and high-quality are used at temperatures up to 350 C.

High-quality carbon structural steel according to GOST 1050 - 74 is divided by type of processing into hot rolled and forged, calibrated, round steel with special surface finish - silver. The standard applies to hot rolled and forged steel grades 08; 10, 15, 20, 25, 30, 35, 40, 45, 50, 58 (55 ps) and 60 with a diameter or thickness of up to 250 mm, as well as calibrated steel and silverfish of all grades.

High-quality carbon structural steel is used for stamping critical products.

High-quality carbon structural steel (GOST 1050-60), depending on the chemical composition, is divided into two groups: I - with a normal content of manganese, II - with a high content of manganese.

High-quality carbon structural steel has a guaranteed chemical composition and guaranteed mechanical properties, as a result of which it is used in the manufacture of heat-treated parts, which at the same time must have sufficient strength. Steel grades 10 and 20 are often used for tubular elements of bearing metal structures, steel grades 20, 35, 40, 45 and 50 - for the above parts, as well as for supporting roller circles.

High-quality carbon structural steel is primarily used for machine parts subjected to heat treatment.

Carbon quality structural steels (Table 4) are denoted by double-digit numbers indicating the average carbon content in hundredths of a percent. Alloy steels are additionally indicated by letters indicating the main alloying elements: B - tungsten, G - manganese, D - copper, M - molybdenum, H - nickel, P - boron, C - silicon, T - titanium, X - chromium, F - vanadium , Yu - aluminum. The numbers after the letters indicate the percentage of the corresponding component; if it is less than or about one percent, then the figure is not set. High-quality alloy steels are additionally marked with the letter A at the end of the designation.

High-quality carbon structural steel is currently smelted in open-hearth and electric furnaces.

High-quality carbon structural steels (GOST 1050 - 74) are used for the manufacture of various machines and mechanisms. They differ from steels of ordinary quality with a lower content of sulfur, phosphorus and other harmful impurities, narrower limits for the carbon content in each grade (taking into account standard deviations) and, in most cases, a higher content of Si and Mn.

High-quality carbon structural steel of grades 0 8, Yukp, 10, 15, 15kp, 20 is painted at the ends in white, steel 25, 30, 35, 40 - in white and yellow, steel 45, 50, 55, 60, 65, 70, 75, 80, 85 - in white and brown, steel 15G, 20G, 25G, ZOG, 35G, 40G - in brown.

High-quality carbon structural steel of grades 0 8, Yukp, 10, 15, 15kp, 20 is painted at the ends in white, steel 25, 30, 35, 40 - in white and yellow, steel 45, 50, 55, 60, 65, 70, 75, 80, 85 - in white and brown, steel 15G, 20G, 25G, ZOG, 35G, 40G - in brown.

High-quality carbon structural steel of grades 0, 8, Yukp, 10, 15, 15kp, 20 is painted on the ends with white paint, steel 25, 30, 35, 40 - white and yellow, steel 45, 50, 55, 60, 65, 70, 75, 80, 85 - white and brown, steel 15G, 20G, 25G, ZOG, 35G, 40G - brown.

For carbon grade structural steel, numbers from 05 to 85 show the average carbon content in hundredths of a percent. Lower case, added after the designation, indicate the degree of metal deoxidation: if the steel is boiling, the letters kp (08kp) are put after the number, half-calm - ps (20ps), calm - without index.

In carbon high-quality structural steels, as well as in carbon steels of ordinary quality with a high content of carbon, mechanical properties also increase.

In addition to the standards of chemical composition, carbon-grade structural steels must satisfy certain standards of mechanical properties - hardness after rolling and after annealing, tensile strength, elongation and narrowing of the cross-sectional area for samples made from normalized billets.

Marked: 0.5kp, 0.8kp, 0.8ps, 0.8, 10kp, 10ps. 20, 25, 30, 35 ... up to 85.15G. 20G 35G. ... up to 70G. the numbers show the average carbon content in hundredths of a percent, G denotes an increased content of manganese.

Low carbon quality steels are widely used for stamped products. The stamping became worse the more carbon in it. These steels are well welded, processed by cutting on metal-cutting machines.

CARBON INSTRUMENTAL STEELScontain from 0.7 to 1.35% carbon. Subdivided into high-quality and high-quality.

Instrumental quality steels are made of grades: U7, U8. U9 ... to U13. the number indicates the carbon content in tenths of a percent.

The letter A: U7A, U8A ... U13A is added to the brand of tool high-quality steels. they contain less sulfur and phosphorus.

|

Carbon structural steels (up to 0.6С) |

Regular quality |

St0, St1 ... to St6 |

hot-rolled steel: beams, rods, channels, angles, sheets, pipes, forgings, rivets, reinforcement. Rails, springs. |

low strength, ductile, easy to pressure, weld well and heat treated. |

|

Carbon structural steels (0.25-1.2%) |

quality |

20, 25, 30, 35, 70G |

stamped parts machine parts - gears, screws, bolts, connecting rods, spindles, shafts, axles |

weld well, machined durable ductile more impact resistance. |

|

Carbon Tool Steels (0.65-1.35 + G0.4) |

quality |

U7, U8. U9 ... to U13 (0.1%) |

Chisels, hammers |

Greater impact resistance, less ductility |

|

Carbon Tool Steels (0.65-1.35 + G0.4) |

high quality less sulfur phosphorus |

U7A, U8A ... U13A |

metalwork tools, measuring tools knives and scissors for metal, rollers of pipe cutters. |

Stronger, hardness the same, better resists impact and calcines. The loss of hardness and cutting ability when heated 200 about rust. |

|

Alloy constructional (low alloyed) carbon 0.1-0.5% |

Low alloyed to 2,5% quality (chrome) quality Less sulfur and phosphorus |

(0.11%) if there are two numbers, if one (0.1%), if not -\u003e 1% C |

Motor shafts, cams, gears Stud bolts Axes Shafts Worms |

Well welded, calcined does not rust, more hardness |

|

Alloyed instrumental (low and high alloyed to 10) carbon 0.95-1.1 |

siliceous Quick cutting |

R-fast cutting, |

Drills, reamers, taps, dies Drills, milling cutters, Broaches, sweeps |

wear resistance, hardenability, strength, hardness impact strength does not lose hardness when heated. 620 about\u003e 10% possess red resistance, (cuts at 700 about) |

|

Alloy special (high alloyed 10-35%) |

Corrosion resistant Heat resistant (silchrome \u003d chromium, silicon, aluminum) heat resistant magnetic steels wear resistant |

E-magnetic Bearing |

Surgical Instrument, Pump Valve Valve for internal combustion engines Gas turbines, jet engines. Transformers, Cores, Relays Track links, bucket visors, rail arrows |

Withstand acid Resist oxidation (scale formation) at high T Do not reduce mechanical properties at high T Wear resistance |

Alloy steel.

Unlike carbon, they contain alloying elements:

chrome –X. , phosphorus - P, Copper - D,

aluminum - Yu, titanium - T,. boron - P,

silicon - C niobium - B. molybdenum - M

nickel - N, cobalt - K,

manganese - G, vanadium - F,

Tungsten - B, zirconium - C,

According to their purpose, alloyed steels are subdivided into structural, tool and steel with special properties.