Engine tests are carried out to evaluate the actual performance of the engines and compare them with the calculated performance, determine the quality of the repairs carried out, and also to check the effect of certain adjustments on the performance of the engine.

As a rule, engine tests are carried out after their complete break-in in accordance with technological requirements.

An analysis of the test results allows you to evaluate the effectiveness of design features and the quality of engine manufacturing (during factory tests of new engine models), or to give a qualitative assessment of the repair performed (during tests after a major or current engine repair).

Types of engine tests

The main types of engine tests can be classified according to the criteria that determine the program and methods of testing.

For the intended purpose distinguish tests:

- search and research;

- finishing;

- acceptance and acceptance (state, interdepartmental);

- inspection (long, short, periodic, control);

- resource (tests for reliability and operational manufacturability);

- certification and others.

According to the means and methods used tests, as well as the conditions and place of their conduct, the following types of tests are distinguished:

- bench;

- polygon;

- road;

- operational;

- tests in special conditions (alpine, tropical, etc.).

The most complete analysis of most types of engine tests can be obtained using bench test methods, which make it possible to assess with a high degree of accuracy the dynamic, operational and economic characteristics of internal combustion engines, as well as the influence of certain factors on these characteristics (for example, adjustments, design and technological solutions). and so on.).

Bench tests of engines

For bench tests of engines, special test benches are used, installed on a powerful concrete foundation with cast-iron plates embedded in it. Recently, non-foundation stands have become widespread, which are simpler and more convenient to operate.

The design of the test bench includes:

- devices for fixing the tested engine on the stand (racks, brackets, flanges, beams, etc.);

- power device for testing the engine without starting it (for the initial assessment of the quality of the assembly and fastening of the engine on the stand, as well as for cold running the engine before testing. As a power device, as a rule, powerful electric motors are used, but other machines can be used;

- braking device to simulate engine load. As a brake, an electric motor is most often used, which was used as an energy source during cold tests, or hydraulic brake mechanisms;

- device for matching the characteristics of the motor and brake (in the case of an electric motor, a powerful variable resistor, in the case of a hydraulic brake - a torque converter);

- equipment that ensures the operation of engine fuel supply systems and exhaust gas removal, lubrication system and engine cooling system;

- test process controls;

- the necessary instrumentation and devices for recording and reading the test parameters.

When testing autotractor engines, electric and hydraulic brakes are most widely used. They are characterized by the greatest stability, i.e. the ability to maintain a constant speed during a short-term imbalance between the engine torque and the brake resistance moment.

The choice of the brake is made according to the maximum power and the maximum speed of the crankshaft of the tested engine. Correspondence of the brake to the tested motor in terms of power and speed capabilities is usually established by superimposing the external speed characteristic of the engine on the external characteristic of the brake.

If the brake characteristics do not meet the necessary requirements to match the characteristics of the tested engine, it is replaced with a more powerful one or an intermediate gearbox is used.

The test stand must have equipment for measuring the following indicators:

- engine torque with an accuracy of ±0.5% of the maximum readings for which the measuring system is designed;

- crankshaft speed with an accuracy of ±0.5%;

- fuel consumption with an accuracy of ±1%;

- coolant temperature with an accuracy of ±2 °С;

- oil temperature in the lubrication system with an accuracy of ±2 °С;

- barometric pressure with an accuracy of ±20 kPa;

- ignition timing or start of fuel supply with an accuracy of ±1 degree of the angle of rotation of the crankshaft of the tested engine;

- boost pressure with an accuracy of 0.05 kPa.

RPM can be measured with two types of instruments: total counters that record the number of revolutions for a certain period of time, and tachometers that give the current value of the rotational speed. Depending on the principle of operation, tachometers can be centrifugal and electric.

Fuel consumption is determined using devices showing volumetric or mass flow. The duration of the experiments should be at least 30 sec.

The air flow is measured using a special flow meter (air meter) or using devices that have a measuring nozzle on the intake tract.

To determine the temperature(depending on the limits, temperature changes and the location of the point whose temperature must be measured) the following instruments are used: liquid thermometers, resistance thermometers, thermocouples and manometric type thermometers.

Ignition timing or start of fuel supply on the stand is determined using a stroboscopic device.

The conditions for bench tests of automobile engines are determined by GOST 14846-81 “Automotive engines. Bench test methods” and provide for compliance with the following requirements:

- the engine under test and the operating materials used must comply with the specifications;

- the temperature of the air surrounding the engine during testing should not exceed +40 °C;

- engine performance should be determined under steady state operation, in which the torque, speed, coolant and oil temperature during the measurement change by no more than ± 2%.

The standard is a state standard and applies to automotive piston and rotary piston internal combustion engines and their modifications. This standard does not apply to free-piston engines.

The GOST 14846-81 standard establishes the scope and test methods for determining:

- power and economic indicators at full loads (net and gross capacities);

- power and economic indicators at partial loads;

- indicators at idle;

- conditional mechanical losses;

- uniform operation of the cylinders;

- non-failure operation;

- exhaust fumes.

The assessment of the capabilities of the tested engine and its compliance with the requirements established by regulatory documents is carried out according to the dynamic and economic characteristics.

During control tests, the external speed characteristic of the net power, the load characteristic at a speed of rotation at the level of the maximum torque, and the idling characteristic are determined.

During acceptance tests, external speed characteristics of net and gross power, load characteristics at least at three different crankshaft speeds, idling characteristics, conditional and mechanical losses, uniformity of cylinder operation, and engine operation are determined.

Test safety requirements

In order to avoid accidents, when testing engines, the most serious attention should be paid to safety issues.

Specially trained personnel who have passed the necessary briefings on labor protection and safety are allowed to work on test benches. Employees from the staff must be provided with the necessary overalls and personal protective equipment (PPE).

Before starting work, the maintenance personnel must check the reliability of fastening the stand to the foundation and the tested engine to the stand, evaluate the technical condition of the stand and the engine, make sure that the test equipment is in full working order, turn on the ventilation system of the room in which the tests are carried out, make sure that the lighting is sufficient.

In the working room of the test station, there should be no foreign objects that impede the free movement of personnel during work, as well as unauthorized persons.

The testing station (laboratory) must be equipped in accordance with sanitary and technical requirements, fire safety and safety requirements.

The room must be equipped with supply and exhaust ventilation, excluding gas contamination and dust content of the air above the norm. Mercury measuring instruments and devices must have special protection, including from the penetration of mercury vapor into the room.

Rotating and moving parts of stands and tested engines must be protected to prevent accidental contact of workers.

Special requirements are placed on noise levels, fire protection and explosion prevention measures.

When testing autotractor engines, the power and economic indicators of their operation are evaluated under various operating conditions, both load and independent external (road, climatic, etc.), taking into account technological factors of manufacture (or overhaul), subsequent operation, reliability, durability, responsiveness to adjustment processes, etc.

SYSTEM OF STATE TESTING OF PRODUCTS

TESTING AND CONTROL

PRODUCT QUALITY

BASIC TERMS AND DEFINITIONS

GOST 16504-81

USSR STATE COMMITTEE ON STANDARDS

DEVELOPED by the USSR State Committee for StandardsPERFORMERSL. M. Zaks, G. K. Martynov(theme leaders), G. V. Anisimova, V. P. Belyavtsev, Yu. S. Veniaminov, G. A. Gukasyan, M. G. Dolinskaya, V. D. Dudko, L. I. Zavalko, A. A. Zenkov, M. G. Iofin, V. V. Kreshchuk, E. N. Leonova, O. G. Lositsky, A. E. Manokhin, M. M. Manzon, V. V. Melentiev, V. P. Nikiforov , V. A. Novikova, E. V. Nikitina, A. G. Osetrov, V. A. Pavlov, O. F. Poslavsky, V. I. Pereponov, V. I. Pronenko, V. N. Smirnov, N K. Sukhov. V. G. Stepanov, E. I. Taver, A. L. Terkel, R. V. Utkina, N. M. Fedotov, I. A. Khalap, S. S. Chernyshev, V. N. Chupyrin, V. I. Churilov, N. G. Sherstyukov, E. P. Schmidt, E. S. Ehrenburg. INTRODUCED by the USSR State Committee for Standards Head of the Department for Attestation and State Product Testing M. A. Ushakov APPROVED AND INTRODUCED BY Decree of the USSR State Committee for Standards of December 8, 1981 No. 5297STATE STANDARD OF THE UNION OF THE SSR

Decree of the USSR State Committee for Standards dated December 8, 1981 No. 5297 established the deadline for introductionfrom 01.01.1982.

This standard establishes the terms and definitions of the basic concepts used in science, technology and production in the field of testing and quality control of products. The terms established by this standard are mandatory for use in all types of documentation, scientific and technical, educational and reference literature. There is one standardized term for each concept. The use of synonymous terms for the standardized term is prohibited. Synonymous terms that are unacceptable for use are given in the standard as reference and are marked with the mark "Ndp". In cases where the necessary and sufficient features of concepts are contained in the literal meaning of the term, the definition is not given, and, accordingly, a dash is put in the “Definition” column. For individual standardized terms in the standard, short forms are given as reference, which are allowed to be used if the possibility of their different interpretation is excluded. Standardized terms are printed in bold, short form in light, invalid terms in italics. The standard provides reference foreign equivalents for a number of standardized terms in English (E) and French (F) languages. The standard contains alphabetical indexes of the terms contained in it in Russian and their foreign equivalents. Reference Appendix 1 provides explanations for some terms marked with an asterisk, Reference Appendix 2 provides a systematization of the types of tests and controls according to their main features.

|

Definition |

1. TESTING |

1. Tests * E. Test F. Essai | Experimental determination of quantitative and (or) quality characteristics properties of the test object as a result of impact on it, during its operation, when modeling the object and (or) impacts. Note. Definition includes assessment and/or control | 2. Conditions tests * E. Test conditions F. Conditions d'essais | The set of influencing factors and (or) modes of operation of the object during testing | 3. Normal test conditions * E. Normal test conditions F. Conditions d'essais normales | Test conditions established by the regulatory and technical documentation (NTD) for this species products | 4. View tests E. Mode of test F. Type d'essai | Classification grouping of tests according to a certain attribute | 5. Category tests E. Category of test F. Category d'essai | Type of tests, characterized by an organizational sign of their implementation and decision-making based on the results of the assessment of the object as a whole | 6. An object tests * E. Item under test F. Objet a essayer | Products under test | 7. Sample for testing E. Test specimen F. Echantillon pour essai | Product or part thereof or sample directly subjected to experiment during testing | 8. Prototype E. Pilot sample F. prototype | A product sample manufactured according to a newly developed working documentation to check by testing its compliance with specified technical requirements in order to make a decision on the possibility of putting it into production and (or) using it for its intended purpose | 9. Test model E. Test model F. Modele pour essai | A product, process, phenomenon, mathematical model that is in a certain correspondence with the test object and (or) influences on it and is capable of replacing them in the test process | 10. Layout for testing E. Test mock - up F. Maquette pour essais | A product representing a simplified reproduction of the test object or part thereof and intended for testing | 11. Method tests E. Test method F. Methode d'essais | Rules for the application of certain principles and means of testing | 12. Volume tests E. Extent of test F. Taille des essais | Characteristics of tests, determined by the number of objects and types of tests, as well as the total duration of tests | 13. Test program * E. Test program F. Program d'essais | Organizational and methodological document, mandatory for implementation, establishing the object and objectives of the tests, the types, sequence and scope of the experiments, the procedure, conditions, place and timing of the tests, provision and reporting on them, as well as responsibility for the provision and conduct of tests | 14. Methodology tests * E. Test procedure F. Procedure d'essais | Organizational and methodological document, mandatory for implementation, including the test method, means and conditions of testing, sampling, algorithms for performing operations to determine one or more interrelated characteristics of the properties of an object, the form of data presentation and evaluation of accuracy, reliability of results, safety and security requirements environment | 15. Certification methods tests E. Approval of test procedure F. Certification de la procedure d'essais | Determination of the values of indicators of accuracy, reliability and (or) reproducibility of test results provided by the method and their compliance with specified requirements | 16. Test tool * E. Test means F. Moyen d'essais | Technical device, substance and (or) material for testing | 17. Test equipment E. Test equipment F. Equipement d'essais | Test tool, which is a technical device for reproducing test conditions | 18. Certification trial equipment E. Certification of test equipment F. Certification de l'equipement d'essais | Determination of the normalized accuracy characteristics of the test equipment, their compliance with the requirements of regulatory and technical documentation and the establishment of the suitability of this equipment for operation | 19. Test system * E. Test system F. Systeme d'essais | A set of test tools, performers and certain test objects interacting according to the rules established by the relevant regulatory documentation | 20. Accuracy of test results E. Accuracy of test results F. Precision des resultats d'essais | Test property characterized by the closeness of test results to the actual values of the characteristics of an object, under certain test conditions | 21. Reproducibility of test methods and results * E. Reproducibility of test methods and results F. Reproducibility des methodes et resultats d "essais | A characteristic determined by the similarity of test results of identical samples of the same object using the same method in different laboratories, by different operators using different equipment | 22. Test data E. Test data F. Donnees d'essais | Values of characteristics of the properties of the object and (or) test conditions, operating time, as well as other parameters that are initial for further processing, recorded during testing | 23. Test result E. Test result F. Resultat d'essais | Evaluation of the characteristics of the properties of the object, establishing the compliance of the object with the specified requirements according to the test data, the results of the analysis of the quality of the functioning of the object during the test | 24. Test report E. Test report F. Proces-verbal d'essais | A document containing the necessary information about the test object, the methods used, means and test conditions, test results, as well as a conclusion on the test results, drawn up in the prescribed manner | 25. Test polygon E. Testing (proving) ground F. Terrain d'essais | Territory and test facilities on it, equipped with test equipment and providing testing of the object in conditions close to the operating conditions of the object | 26. Test organization E. Test organization F. Organisme d'essais | An organization that, in accordance with the established procedure, is entrusted with testing certain types of products or carrying out certain types of tests | 27. Parent organization for state product testing | An organization that has been approved in accordance with the accepted procedure for conducting tests at the state level of the established most important types of products for industrial, technical and cultural purposes | 28. State testing center E. State testing center F. Center national d'essais | A specialized subdivision of the head organization for state testing, designed to carry out state tests of established critical types of products for industrial, technical, cultural and community purposes | 29. Republican (regional) testing center E. Republican (regional) testing center F. Center republicain (regional) d'essais | An organization approved in accordance with the accepted procedure for carrying out certain categories of tests of fixed types of products manufactured and (or) developed by enterprises and organizations of the republic (region), regardless of their departmental subordination | 30. Departmental test center E. Departmental testing center F. Center sectoriel d'essais | An organization entrusted by a ministry or department with carrying out certain categories of testing of fixed types of products manufactured and (or) developed by enterprises and organizations of this ministry or department | 31. Test unit E. Testing division F. Unite d'essais | A subdivision of an organization to which the management of the latter is entrusted with conducting tests for its own needs | 32. Basic test unit of the parent organization Base division | A subdivision appointed in accordance with the accepted procedure for testing certain types of products or types of tests from among those assigned to the head organization for state testing | 33. Stronghold of the parent organization for state product testing strong point | An organization that is a consumer of products subject to testing, appointed in the accepted manner to test these products in operational conditions | 34. E. Certification of testing organizations and divisions F. Agrement des organismes et des unites d'essais | Certification of the competence of testing organizations and divisions and their equipment, ensuring that all tests of fixed types of products and (or) types of tests provided for by the regulatory and technical documentation are carried out at the proper technical level |

Test types |

35. Research tests * E. Investigation test F. Essais de recherche | Tests carried out to study certain characteristics of the properties of an object | 36. Control tests E. Check test F. Essais de controle | Tests carried out to control the quality of the object | 37. Comparative tests E. Comparative test F. Essais comparatifs | Tests of similar or identical objects carried out under identical conditions to compare the characteristics of their properties | 38. Definitive tests E. Determinative test F. Essais de determination | Tests carried out to determine the values of the characteristics of the object with the given values of the indicators of accuracy and (or) reliability | 39. State tests * E. State test F. Essais officiels | Testing of identified critical products by a parent government testing organization or acceptance testing by a government commission or testing organization that has been granted the right to conduct them | 40. Interdepartmental tests * E. Interdepartmental test F. Essais intersectoriels | Product tests conducted by a commission of representatives of several interested ministries and/or departments, or acceptance tests of established types of products for acceptance constituent parts an object developed jointly by several departments | 41. Departmental tests E. Departmental test F. Essais sectoriels | Tests conducted by a commission of representatives of the interested ministry or department | 42. Finishing tests Ndp. Structural tests E. Developmental test F. Essais de finition | Research tests carried out during the development of products in order to assess the impact of changes made to it to achieve the specified values of its quality indicators | 43. Preliminary tests E. Preliminary test F. Essais preliminaires | Control tests of prototypes and (or) pilot batches of products in order to determine the possibility of their presentation for acceptance tests | 44. Acceptance tests * E. Acceptance test F. Essais d'acceptation | Control tests of prototypes, pilot batches of products or products of a single production, carried out respectively in order to resolve the issue of the advisability of putting these products into production and (or) use for their intended purpose | 45. Qualification tests E. Qualification test F. Essais de qualification | Control tests of the installation series or the first industrial batch, carried out in order to assess the readiness of the enterprise to produce products of this type in a given volume | 46. Bearer trials E. Predelivery test F. Essais de presentation | Control tests of products carried out by the technical control service of the manufacturer before presenting it for acceptance by a representative of the customer, consumer or other acceptance bodies | 47. Acceptance tests * E. Approval test F. Essais de reception | Control tests of products during acceptance control | 48. Periodic tests E. Periodical test F. Essais periodiques | Control tests of manufactured products, carried out in the volumes and within the time limits established by the regulatory and technical documentation, in order to control the stability of product quality and the possibility of continuing its production | 49. Inspection tests E. Inspection test F. Essais d'inspection | Control tests of established types of manufactured products, carried out on a selective basis in order to control the stability of product quality by specially authorized organizations | 50. Type tests Ndp. Verification tests E. Type test F. Essais type | Control tests of manufactured products, carried out in order to assess the effectiveness and feasibility of changes to the design, recipe or technological process | 51. Qualification tests E. Evaluation test F. Essais d'attestation | Tests carried out to assess the level of product quality during its certification by quality categories | 52. Certification tests * E. Certification test F. Essais de certification | Control tests of products carried out in order to establish the conformity of the characteristics and properties of national and (or) international regulatory and technical documents | 53. Laboratory testing E. Laboratory test F. Essais de laboratoire | Object tests carried out in laboratory conditions | 54. Bench tests * E. Bench test F. Essais au banc | Object tests carried out on test equipment | 55. Field tests E. Ground test F. Essais au terrain | Object tests carried out at the test site | 56. Natural tests * E. Verification test in situ F. Essais in situ | Testing an object under conditions corresponding to the conditions of its intended use with direct evaluation or control of the determined characteristics of the object's properties | 57. Model tests * E. Test with modeling F. Essais avec utilisation des modeles | - | 58. Performance test * E. Field test F. Essais pratiques | Object tests carried out during operation | 59. Normal tests E. Normal test F. Essais normaux | Tests, methods and conditions of which provide obtaining the necessary amount of information about the characteristics of the properties of the object in the same time interval as in the envisaged operating conditions. | 60. Accelerated Trials E. Accelerated test F. Essais acceleres | Tests, the methods and conditions of which provide the necessary information about the characteristics of the properties of the object in a shorter period than during normal tests | 61. Reduced Trials E. Reduced test F. Essais tronques | Tests carried out according to an abbreviated program | 62. Mechanical tests * E. Mechanical test F. Essais mecaniques | Tests for the impact of mechanical factors | 63. Climate test * E. Environmental test F. Essais climatiques | Tests for the impact of climatic factors | 64. Thermal testing * E. Thermal test F. Essais thermiques | Thermal Factor Testing | 65. Radiation testing E. Radiation test F. Essais de radiation | Tests for the influence of radiation factors | 66. Electromagnetic testing * E. Electromagnetic test F. Essais electromagnetiques | Electromagnetic Field Tests | 67. Electrical tests * E. Electric test F. Essais electriques | Impact Tests electrical voltage, current or zero | 68. Magnetic testing * E. Magnetic test F. Essais magnetiques | Magnetic Field Tests | 69. Chemical testing * E. Chemical test F. Essais de resistance chimique | Tests for the impact of special environments | 70. Biological tests * E. Biological F. Essais biologists | Tests for the influence of biological factors | 71. non-destructive tests E. Non-destructive test F. Essais non-destructifs | Tests using non-destructive control methods | 72. Destructive tests E. Destructive test F. Essais destructifs | Tests using destructive control methods | 73. Strength tests E. Strength test F. Essais d'endurance | Tests carried out to determine the values of influencing factors that cause the values of the characteristics of the properties of the object to go beyond the established limits or its destruction | 74. Stability tests E. Stability test F. Essais de stabilite | Tests carried out to control the ability of a product to perform its functions and maintain parameter values within established limits during the action of certain factors on it | 75. Functional tests E. Functional test F. Essais functionnels | Tests conducted to determine the values of the indicators of the purpose of the object | 76. Reliability testing E. Reliability test F. Essais de fiabilite | Tests carried out to determine the reliability performance under specified conditions | 77. Safety tests E. Safety test F. Essais de securite | - | 78. Tests for transportability E. Transportability test F. Essais d'aptitude au transport | - | 79. Boundary tests E. Marginal test F. Essais limits | Tests carried out to determine the dependencies between the maximum permissible values of the parameters of the object and the operating mode | 80. Technological tests E. In-process test F. Essais de technicite | Tests carried out during the manufacture of products in order to assess their manufacturability |

2. CONTROL |

81. Technical control * E control. Inspection F. Control technique | Checking the compliance of the object with the established technical requirements | 82. Control quality products E. Product quality inspection F. Controle de la qualite des produits | Control of quantitative and (or) qualitative characteristics of product properties | 83. Evaluation quality products E. Assessment of product quality F. Estimation de la qualite des produits | Determination of values of product characteristics with indication of accuracy and (or) reliability | 84. Object of technical control * E. Item under inspection F. Objet a controler | Controlled products, processes of their creation, application, transportation, storage, maintenance and repair, as well as related technical documentation | 85. View control E. Mode of inspection F. Type de controle | Classification grouping of control according to a certain attribute | 86. Volume control E. Amount of inspection F. Taille du controle | The number of objects and the totality of controlled features established for control | 87. Method control E. Inspection method F. Methode de controle | Rules for the application of certain principles and controls | 88. Method destructive control E. Method of destructive inspection F. Methode destructive | Method of control, which may violate the suitability of the object for use | 89. Method non-destructive control E. Method of non-destructive inspection F. Method of non-destructive | Method of control, in which the suitability of the object for use should not be violated | 90. Means control E. Inspection means F. Moyens de controle | Technical device, substance and (or) material for control | 91. Controlled sign E. Characteristic under control F. Caractere a controler | Characteristic of the object subjected to control | 92. Control dot * E. Point of inspection F. Point de controle | Location of the primary source of information about the controlled parameter of the control object | 93. Control sample * E. Reference specimen F. Specimen temoin | A product unit or part thereof, or a duly approved sample, the characteristics of which are taken as a basis for the manufacture and control of the same product | 94. System control E. Inspection system F. Systeme du controle | A set of controls, performers and certain objects of control interacting according to the rules established by the relevant regulatory documentation | 95. System departmental control E. Departmental management system F. Systeme du controle sectoriel | The control system carried out by the bodies of the ministry or department | 96. Automated control system * E. Automated control system F. Systeme de controle automatise | Control system that provides control with partial direct participation of a person | 97. Automatic control system * E. Automatic control system F. Systeme de controle automatique | Control system that provides control without direct human participation |

Types of control |

98. Production control * E. Manufacturing supervision F. Controle de fabrication | Control carried out at the stage of production | 99. Operational control * E. Field inspection F. Controle en utilization | Control carried out at the stage of product operation | 100. Input control E. incoming inspection F. Controle a l'entree | Control of the supplier's products received by the consumer or customer and intended for use in the manufacture, repair or operation of products | 101. Operating control E. Operational inspection F. Controle des operations | Inspection of a product or process during or after a manufacturing operation | 102. Acceptance control E. Acceptance inspection F. Controle de reception | Control of products, based on the results of which a decision is made on its suitability for supply and (or) use | 103. Inspection control E. Inspection check-up F. Audit | Control carried out by specially authorized persons in order to verify the effectiveness of previously performed control | 104. Total control E. 100% inspection F. Controle a 100% | Control of each unit of production in a batch | 105. Selective control E. Sampling inspection F. Controle par echantillonnage | According to GOST 15895-77 * _________ * GOST R 50779.10-2000, GOST R 50779.11-2000 apply on the territory of the Russian Federation | 106. Volatile control * E. Casual inspection F. Controle volant | Random Time Control | 107. Continuous control E. Continuous inspection F. Controle continu | Control, in which the flow of information about the controlled parameters occurs continuously | 108. Periodic control E. Periodical inspection F. Controle periodique | Control, in which the receipt of information about the controlled parameters occurs at set intervals | 109. destructive control E. Destructive inspection F. Controle destructif | - | 110. non-destructive control E. Non-destructive inspection F. Controle non-destructif | - | 111. Measuring control E. Control by measurement F. Controle par mesures | Control carried out using measuring instruments | 112. Registration control E. Registration control F. Controle par enregistrement | Control carried out by recording the values of controlled parameters of products or processes | 113. Organoleptic control * E. Organoleptic inspection F. Controle organoleptique | Control, in which the primary information is perceived by the senses | 114. Visual control E. Visual inspection F. Controle visuel | Organoleptic control exercised by the organs of vision | 115. Technical inspection E. Technical check-up F. Visite technique | Control carried out mainly with the help of the sense organs and, if necessary, means of control, the nomenclature of which is established by the relevant documentation |

INDEX

Test Equipment Qualification 18

Certification of testing organizations and divisions 34

Test method certification 15

Test type 4

Type of control 85

Reproducibility of methods and test results 21

Test Data 22

Trials 1

Attestation tests 51

Biological tests 70

Departmental tests 41

State tests 39

Boundary tests 79

Finishing tests 42

Research tests 35

Inspection tests 49

Qualification tests 45

Climatic tests 63

Structural tests 42

Control tests 36

Laboratory tests 53

Magnetic tests 68

Interdepartmental tests 40

Mechanical tests 62

Testing with Models 57

Safety tests 77

Reliability testing 76

Identification tests 38

Strength tests 73

Transportability tests 78

Stability tests 74

Field tests 56

Non-destructive tests 71

Tests normal 59

Periodic tests 48

Field tests 55

Preliminary tests 43

Bearer tests 46

Acceptance tests 47

Acceptance tests 44

Verification tests 50

Radiation tests 65

Destructive tests 72

Certification tests 52

Reduced tests 61

Comparative tests 37

Bench tests 54

Thermal tests 64

Technological tests 80

Type tests 50

Tests accelerated 60

Functional tests 75

Chemical tests 69

Operational tests 58

Electrical tests 107

Electromagnetic tests 66

Visual control 114

Selective control 105

Input control 100

Measuring control 111

Inspection control 103

Product quality control 82

Volatile control 106

Continuous monitoring 107

Non-destructive testing 110

Operational control 101

Organoleptic control 113

Periodic control 108

Acceptance control 102

Production control 98

Destructive control 109

Registration control 112

Continuous control 104

Technical control 81

Operational control 99

Test layout 10

Test method 11

Test model 9

Control method 87

Destructive control method 88

Non-destructive control method 89

Test Method 14

Test equipment 17

Control sample 93

Scope of control 86

Test scope 12

Test object 6

Object of technical control 84

Experimental sample 8

Stronghold of the parent organization for state testing 33

Test organization 26

Lead organization for state testing of products 27

Technical inspection 115

Product quality assessment 83

Probation Unit 31

Subdivision test basic 32

Test site 25

Feature controlled 91

Test program 13

Test report 24

Test result 23

Test System 19

Control system 94

Automated control system 96

Automatic control system 97

Departmental control system 95

Test tools 16

Control 90

Test conditions 2

Test conditions normal 3

Control point 92

Accuracy of test results 20

Departmental testing center 30

State testing center 28

Republican testing center (regional) 29

(Changed edition. Rev. No. 1).

ENGLISH INDEX OF TERMS 1

Accelerated test 60

Acceptance inspection 102

Acceptance test 44

Accuracy of test results 20

Amount of inspection 86

Approval of test procedure * 15

Approval test 47

Assessment of product quality 83

Automated control system 96

Automatic control system 97

Base testing division of head organization 32

Biological test 70

Casual inspection** 106

Category test 5

Certification of test equipment * 18

Certification of testing organizations and divisions * 34

Certification test 52

Characteristic under control 91

Comparative test 37

Continuous inspection 107

Control by measurement 111

Departmental management system 95

Departmental test 11

Departmental testing center 30

Destructive inspection 110

Destructive inspection method 88

Destructive test 72

Development test 42

Durability test 76

electric test 67

Electromagnetic test 66

environmental test 63

Evaluation test * 51

Extent of test 12

Field inspection 99

Functional test 75

Head organization for state product test 27

Incoming inspection 100

In-process test * 80

100% inspection 104

Inspection check-up 103

inspection means 90

Inspection method 87

Inspection system 94

Inspection test 49

Interdepartmental test 40

Investigation test 35

Item under inspection 84

item under test 6

Laboratory test 53

Magnetic test 68

Manufacturing Supervision 98

marginal test 79

mechanical test 62

Mode of inspection 85

Non-destructive inspection 110

Non-destructive inspection method 89

Non-destructive test 71

Normal test conditions 3

Operational inspection 101

Organoleptic inspection 113

Periodical inspection 108

Periodical test 48

Point of inspection 92

Predelivery test*46

Preliminary test 43

Product quality assessment 83

Product quality inspection 82

Qualification test 45

Radiation test 65

Reference specimen 93

Registration control ** 112

Reliability test 76

Reproducibility of test methods and results 21

Republican (regional) testing center** 29

Sampling inspection 105

Stability test 74

Stale testing center 28

strength test 73

Technical check-up 115

test conditions 2

test equipment 17

Test procedure 14

Test with modeling 57

Test division 31

Testing (proving) ground 25

Testing organization 26

Testing station accredited by head organization 33

Transportability test 75

Verification test in situ * 55

Visual inspection 114

ALPHABETICAL INDEX OF TERMS IN FRENCH 1

Agrement des organismes et des unites d'essais 34

Caractere a controller 91

Category d'essais 5

Center national d'essais 28

Center republicain (regional) d'essais 29

Center sectoriel d'essais 30

Certification de la procedure d'essais 15

Certification de 1'equipment d'essais 14

Conditions d'essais 2

Conditions d'essais normales 3

Controle a 100% 101

Controle a 1’entree 100

Controle continu 107

Controle de fabrication 98

Controle de la qualite des produits 82

Controle de reception 102

Controle des operations* 101

Controle destructif 109

Controle en utilization 99

Controle non-destructif 110

Controle organoleptique 113

Controle par echantillonnage 105

Controle par enregistrement 112

Controle par mesures 111

Controle periodique 108

Controle sectoriel 93

Control technique 81

Control visual 114

Controle volant 106

Donnees d'essais 22

Echantillon pour essai 7

Equipement d'essais 17

Essais acceleres 60

Essais au bank 54

Essais au terrain 55

Essais avec utilization des modeles * 57

Essais biologists 70

Essais climatiques 63

Essais comparatifs 37

Essais d'acceptance 44

Essais d'aptitude au transport 78

Essais d'attestation * 51

Essay decertification 52

Essais de controle 36

Essais de determination 38

Essais d'endurance * 73

Essais de fiabilite 76

Essais de finition 42

Essais de labouratoire 53

Essay de presentation 46

Essais de radiation 65

Essais de recherches 35

Essais de resistance chimique 69

Essais de stabilite * 74

Essais destructits 72

Essais de qualification 45

Essais de reception 47

Essais de securite 77

Essais de technicite** 80

Essais inspection*49

Essais electriqucs 67

Essais electromagnetiques 6

Essais functionnels 75

Essais in situ 56

Essais intersectoriels 40

Essais limits 79

Essais magneliques 68

Essais mecaniques 62

Essais non-destructifs 71

Essais normaux 59

Essais ofticiels 39

Essais periodiques 48

Essais pratiques 58

Essais preliminaires 43

Essais secloriels 41

Essais thermiques 64

Essais tronques 61

Estimation de la qualite des produits 83

Maquelle pour essais 10

Methode de controle 87

Methode d'essais 11

Methode destructive 88

Methode non-destructive 89

Modele pour essais 9

Moyen de controle 90

Moyen d'essais 16

Objet a essayer 6

Objet a controller 84

Organisme d'essais 26

Organisme pilote pour les essais officiels des produits 27

Point de controle 92

Precision des resultats d'essais 20

Procedure d'essais 14

Proces verbal d'essais 24

Program d'essais 13

Reproducibility des methodes et resultsats d "essais 21

Resultats d'essais 23

Specimen temoin 93

Systeme de controle automatique 97

Systeme de controle automatise 96

Systeme d'essais 19

Systeme du controle 94

Systeme du controle sectoriel 95

Taille des essays * 12

Taille du controle*86

Terrain d'essais 25

Type de controle 85

Type d'essais 4

Unite d'essais 31

Unite d'essais de base d'un organisme pilote ** 32

Visit technique 115

1 Terms marked with a single asterisk (*) are approximate equivalents; terms marked with two asterisks (**) should be considered translations; terms without designations are full equivalents. (Changed edition. Rev. No. 1).

ANNEX 1

Reference

EXPLANATION TO SOME TERMS

To the term "Tests" (clause 1)

Experimental determination of the characteristics of the properties of an object during testing can be carried out by using measurements, analyses, diagnostics, organoleptic methods, by recording certain events during testing (failures, damages), etc. Characteristics of the properties of an object during testing can be evaluated if the task of testing is to obtain quantitative or qualitative assessments, but can be controlled if the task of testing is only to establish that the characteristics of the object comply with the specified requirements. In this case, the tests are reduced to control. Therefore, a number of types of tests are control, during which the task of control is solved. The most important feature of any test is the adoption of certain decisions based on their results. of the object functioning. Determination of the characteristics of the object during testing can be carried out both during the functioning of the object and in the absence of functioning, in the presence of influences, before or after their application.

To the term "Test conditions" (clause 2)

The test conditions include external influencing factors, both natural and artificially created, as well as internal influences caused by the operation of the object (for example, heating caused by friction or the passage of electric current) and the modes of operation of the object, methods and place of its installation, mounting, fastening, travel speed, etc. (Changed edition. Rev. No. 1).

To the term "Normal test conditions" (clause 3)

Normal test conditions (values of influencing factors, modes of operation) must be specified in the NTD for test methods for specific types of products. So, for example, normal climatic conditions tests for various kinds other technical products. Normal conditions for performing linear and angular measurements, etc.

A wide range of types of tests combined in the category of tests is characterized by organizational features of their implementation, namely, the level (state, interdepartmental, departmental tests), development stages (preliminary, acceptance), various types of tests of finished products (qualification, acceptance, periodic , typical, etc.). Based on the results of all these tests, an assessment of the object as a whole is made and an appropriate decision is made - on the possibility of presenting the product for acceptance tests, on putting the product into production, on the completion of mastering mass production, on the possibility of its continuation, on assigning a product to one or another quality category, etc.

To the term "Test Object" (clause 6)

The main feature of the test object is that, based on the results of its tests, one or another decision is made on this object - on its suitability or rejection, on the possibility of presenting it for the next test, on the possibility of serial production, and others. Depending on the type of product and the test program, the object tests can be a single product or a batch of products subjected to complete or selective control, a separate sample or a batch of products from which a sample specified in the RTD is taken. The test object can be a mock-up or model of the product and the decision based on the test results can relate directly to the mock-up or model. However, if, when testing a product, some of its elements have to be replaced by models for testing or certain characteristics of the product are determined on models, then the object of testing remains the product itself, the assessment of the characteristics of which is obtained on the basis of model tests. Examples: 1. A computer is being tested as part of input and output devices, a memory device, an arithmetic device, etc. The computer as a whole is considered to be the test object.2. One of several channels of the communication system is presented for testing. In this case, the test object is the given channel of the communication system.3. A batch of TVs with a volume of N. From N products are sampled in n products for which the characteristics of their properties are determined. Based on the use of selective methods of evaluation and control, the test results apply to the entire batch of N TVs. In this case, the test object is the entire batch of N TVs.

To the term "Test Program" (clause 13)

The test program must contain test methods or references to them, if these methods are designed as independent documents.

To the term "Test Method" (clause 14)

The test procedure, which essentially determines the technological process of their implementation, can be drawn up in an independent document or in a test program, or in a regulatory and technical document for products (standards, specifications). The test procedure must be certified.

To the term "Means of testing" (clause 16)

The concept of a test tool covers any technical means used in testing. This includes, first of all, test equipment (clause 17), which refers to the means of reproducing test conditions (clause 2). Test tools include measuring instruments, both built into the test equipment and used in tests to measure certain characteristics of an object or control test conditions. Test tools should also include auxiliary technical devices for fixing the test object, recording and processing results. Test tools also include basic and auxiliary substances and materials (reagents, etc.) used in testing.

To the term "Test system" (clause 19)

The main characteristic feature of any testing system is the presence of some organized set of performers (organizations or individuals) who have the necessary testing tools and interact with certain test objects according to established rules. In this sense, they speak, for example, of a system for testing agricultural machines, based on the machine-testing stations of the State Committee for Agriculture; on the system of state testing of measuring instruments, based on metrological institutes and regulated by the relevant state standards; on the system of state testing of the most important types of products, based on the parent organizations for state testing and regulated by the relevant set of regulatory documents.

to the term "Reproducibility of test methods and results” (p. 21)

The reproducibility of test methods and results, except for the test procedure (including the method, means, algorithm, etc.) may largely depend on the properties of the test object. If the object is, for example, a batch of products subjected to random tests, then such tests supplier and customer tests may be carried out on identical samples selected from a given lot, in which case the heterogeneity of the products can significantly, sometimes decisively, affect the reproducibility of test results. (Changed edition. Rev. No. 1).

To the term "Research tests" (p. 35)

Research tests are carried out with the aim of: determining or evaluating the quality indicators of the functioning of the tested object in certain conditions of its use; choosing the best modes of using the object or the best characteristics of the object properties; comparing many options for implementing the object during design and certification; building a mathematical model of the functioning of the object (estimating the parameters of the mathematical model); selection of significant factors affecting the quality indicators of the object's functioning; choice of the type of mathematical model of the object (among a given set of options).

To the term "State tests" (p. 39)

Decree of the Central Committee of the CPSU and the Council of Ministers of the USSR No. 695 of July 12, 1979 extended the concept of "state tests" to the most important types of products for industrial, technical and cultural purposes. The parent organizations for state testing of these types of products, approved in accordance with the decree, are entrusted with conducting a wide range of state tests, including, along with acceptance tests, also tests of serial products, imported products, certification and other types of tests. Accordingly, the content of the concept of “state tests” for the indicated most important types of products has been changed. At the same time, for other most important types of products that are not covered by the activities of the parent organizations, the previous content of the concept of “state tests” has been retained as acceptance tests conducted by the state commission with the addition of the possibility of their carried out by organizations to which such a right has been granted.

To the term "Interdepartmental tests" (p. 40)

For certain types of products, the concept of “interdepartmental testing”, by decision of the ministries concerned, may refer only to certain categories of tests (for example, only to acceptance tests), regardless of the fact that representatives of different ministries may also participate in commissions for testing other categories.

To the term "Acceptance tests" (clause 44)

Acceptance tests of prototypes or batches of products are carried out to resolve the issue of the advisability of putting these products into production, and acceptance tests of single-piece production products are carried out to resolve the issue of the advisability of transferring these products to operation (GOST 15.001-88 *). * On the territory of the Russian Federation, GOST R 15.201-2000 applies. (Changed edition. Rev. No. 1).

To the term "Acceptance tests" (clause 47)

Acceptance tests are usually carried out by the product manufacturer. If the manufacturer has a representative of the customer, acceptance tests are carried out by him in the presence of the manufacturer's representative.

To the term "Certification tests" (p. 52)

The procedure and conditions for conducting certification tests are established in the certification documentation. Based on the results of these tests, the compliance of product quality with the requirements of national or international standards is checked.

To the term "Bench tests" (p. 54)

The concept of "test bench" in various industries is interpreted in different ways. So, for example, in the vibration testing technique, a vibration stand is understood to be a vibrating table on which the tested product is installed, and the whole complex of control and measurement tools together with the table is called a vibration installation. An engine test stand, on the contrary, includes the whole complex of tools necessary to carry out these tests. There are big discrepancies in the interpretation of this term and in foreign terminology. Since the term “test equipment” (clause 17) as a test tool for reproducing test conditions fully covers all interpretations of the concept of “test bench”, then, accordingly, the common term “bench tests” is defined as tests carried out on test equipment.

To the term "Field tests" (p. 56)

Full-scale tests are implemented if three main conditions are met: 1. The directly manufactured products (i.e., the test object) are subjected to tests without the use of models of the product or its components.2. Tests are carried out under conditions and under impacts on products that correspond to the conditions and impacts of use for the intended purpose.3. The determined characteristics of the properties of the test object are measured directly without using analytical dependencies that reflect the physical structure of the test object and its components. It is allowed to use a mathematical apparatus for statistical processing of experimental data. Examples: 1. An all-round radar station is presented for testing. The purpose of the tests is to determine the range of detection by this station of an aircraft (LA) of a given type with a given reflective surface. During the tests, aircraft flights with a given reflective surface are carried out along pre-selected routes, the radar detection range is determined directly (radar coordinates are known in advance, aircraft coordinates are known for any moment of time), the detection time is determined during testing. In this case, all three of the above conditions are met. Consequently, the radar is subjected to full-scale tests. Tests will remain full-scale if, instead of an aircraft, some physical body with characteristic movements close to the characteristics of an aircraft of a given type with a given reflective surface is used.2. Under the conditions of example 1, the tests are carried out without the use of an aircraft. During the tests, the sensitivity of the radar receiving path, the transmitter power, the frequency of the radiated energy, etc. are directly measured. The measurement results are substituted into the radar formula and the detection range of the radar is determined. In this case, the third of the above conditions is not met (in fact, a mathematical model is used - the radar formula) and the radar tests are not full-scale.

To the term "Tests using models" (paragraph 57)

Tests using models include calculations on mathematical or physical and mathematical models of the test object and (or) impacts on it in combination with full-scale tests of the object and its components (experimental-theoretical test method), as well as the use of a physical model of the test object or its constituent parts. Field test data are required as initial data for modeling, and are also used to verify the correct functioning of the test object (correct docking of the component parts of the object, the ability of the object to perform the tasks for which it is intended, etc.).

To the term "Performance tests" (clause 58)

One of the main types of operational tests is pilot operation. In addition, controlled operation can be carried out, which to some extent can also be conditionally referred to as operational tests. Controlled operation is a natural operation, the course and results of which are observed by personnel specially designed and trained for this purpose (additional or full-time) and guided by documentation also developed specifically for the collection, recording and primary processing of information, the source of which is controlled operation.

To terms

"Mechanical tests" (p. 62),

"Climatic tests" (p. 63),

"Thermal tests" (p. 64),

"Radiation testing" (p. 65),

"Electrical tests" (p. 67)

"Electromagnetic testing" (p. 66)

"Magnetic tests" (p. 68),

"Chemical testing" (p. 69),

"Biological tests" (p. 70)

The listed types of tests are carried out to check the performance and (or) maintain the appearance of products within the limits established by the NTD, under conditions and (or) after exposure to these factors. (Changed edition. Rev. No. 1).

To the term "Technical control" (p. 81)

The essence of any control is reduced to the implementation of two main stages: 1. Obtaining information about the actual state of some object, about the signs and indicators of its properties. This information can be called primary.2. Comparison of primary information with pre-established requirements, norms, criteria, i.e. detection of compliance or non-compliance of actual data with the required (expected). Information about the discrepancy (discrepancy) between the actual and required data can be called secondary. The object, the data on the state and (or) properties of which are subject to comparison with the established requirements during control, can be a product or process (see explanations and examples for the term "Object of control") .In some cases, the time limit between the first and second stages of control is indistinguishable. In such cases, the first stage may not be clearly expressed or may be practically not observed. A typical example is the control of the size by a caliber, which is reduced to the operation of comparing the actual and maximum allowable values size. Further, the secondary information is used to develop appropriate control actions on the object subjected to control. In this sense, any control is always active. It should be noted in this regard that any control, in addition, should always be preventive to one degree or another, since secondary information can be used to improve the development, production and operation of products, to improve its quality, etc. However, the adoption decisions based on the analysis of secondary information, the development of appropriate control actions is no longer a part of control. This is the next stage of management, based on the results of control - an integral and essential part of any management. During technical control, primary information is compared with the technical requirements recorded in the regulatory documentation, with the signs of a control sample, with data recorded using a caliber, etc. At the product development stage, technical control consists, for example, in checking the conformity of a prototype and (or ) the developed technical documentation, the rules for registration and the terms of reference. At the manufacturing stage, technical control covers the quality, completeness, packaging, labeling and quantity of products presented, the course (state) of production processes. At the stage of product operation, technical control consists, for example, in checking compliance with the requirements of operational and repair documentation.

To the term "Object of technical control" (p. 84)

The objects of technical control are objects of labor (for example, products of the main and auxiliary production in the form of products, materials, technical documentation, etc.), means of labor (for example, equipment of industrial enterprises) and technological processes.

To the term "Checkpoint" (p. 92)

The control point of the control object can be a part (element) of the controlled object or be at some distance from it (for example, monitoring the content of carbon monoxide in exhaust gases by its content in the atmosphere outside the pipe). The control point is usually where the sensor is located, the beginning of the output from the electrical circuit to the measuring device, etc. The control point is the established place for sampling the substance.

To the term "Reference sample" (paragraph 93)

The control sample can be used to normalize quality indicators. When controlling the quality of products, it is allowed to use duplicates of control samples. A control sample of products should be distinguished from the basic sample of products used in its certification (establishing a quality category). its reproduction in products during the production process.

To the terms "Automatic control system" (p. 97), "Automated control system" (p. 96)

The automatic control system consists of controls that perform all the functions of controllers. In an automated control system, control tools perform only part of the functions of controllers.

To the term "Industrial control" (p. 98)

Production control, as a rule, covers all auxiliary, preparatory and technological operations.

To the term "Operational control" (p. 99)

The objects of operational control can be operated products and the operation process.

To the term "Flying control" (p. 106)

The effectiveness of volatile control is determined by its suddenness, the rules for ensuring which must be specially developed. Volatile control, as a rule, is carried out directly at the place of manufacture, repair, storage, etc.

To the term "Organoleptic control" (p. 113)

Organoleptic control is based on the perceptions of the senses (sight, hearing, smell, taste and touch) of such information that is not presented in numerical terms. smell, etc.). In organoleptic control, control means that are not measuring, but increase the resolution or susceptibility of the senses, can be used.

APPENDIX 2

Reference

Systematization of types of tests according to the main features

|

Sign of the type of tests |

Type of tests |

| Assignment of tests | Research |

| Control | |

| Comparative | |

| Determinants | |

| Level of testing | State |

| Interdepartmental | |

| Departmental | |

| Product Development Stages | Finishing |

| preliminary | |

| Acceptance | |

| Finished product testing | Qualifying |

| bearer | |

| Acceptance | |

| Periodic | |

| Inspection | |

| Typical | |

| Attestation | |

| Certification | |

| Conditions and place of testing | Laboratory |

| Poster | |

| Polygon | |

| Natural | |

| Model tests | |

| Operational | |

| Test duration | Normal |

| Accelerated | |

| Abbreviated | |

| Type of impact | Mechanical |

| climatic | |

| Thermal | |

| Radiation | |

| Electrical | |

| electromagnetic | |

| Magnetic | |

| Chemical | |

| Biological | |

| Impact result | non-destructive |

| Destructive | |

| Durability Tests | |

| Strength tests | |

| Stability tests | |

| Defined characteristics of the object | Functional |

| Reliability Tests | |

| Safety Tests | |

| Transportability Tests | |

| Boundary tests | |

| Technological tests |

Systematization of types of control according to the main features

|

Sign of the type of control |

Type of control |

|

| Stage of creation and existence of products | Industrial | |

| Operational | ||

| Stage of the production process | Input | |

| Operating | ||

| Acceptance | ||

| Inspection | ||

| Completeness of control coverage | Solid | |

| Selective | ||

| Volatile | ||

| Continuous | ||

| Periodic | ||

| Influence on the object of control | destructive | |

| non-destructive |

Gosthelp.ru - When using the material, a link to the site is required. (On the Internet - hyperlink)

Bench tests differ from other types of tests (field, field, operational) by the high stability of the set and maintained influencing factors (loading conditions, temperature, humidity, dust content and other factors affecting the functioning of the structure), the accuracy of their regulation, the possibility of in-depth observations of working processes, including those in hard-to-reach areas, increased accuracy of measurement and registration of parameters. On the stands, information can be obtained that no other tests can give, for example, the strength indicators of parts, indicator power, etc.

Bench tests are classified according to various criteria and are mainly divided into the following groups:

Testing of individual parts, components and assemblies;

Tests of complete machines;

Testing of individual parts, assemblies and assemblies on a complete machine (or part thereof) installed on the stand;

Static and dynamic tests;

Tests with destruction and without destruction;

On universal or unique bench installations;

Strength, fatigue, wear, vibration, etc.

Engine testing are carried out on stands with hydraulic

calic, electric or inductor brake installations (Fig. 1, 2).

During bench tests, the following are determined:

1. Performance indicators for adjustments and configuration specified by the manufacturer. Based on the test results, the following are determined: characteristics of indicated power, speed characteristics of effective power - external characteristic with a regulatory branch, characteristics of forced idling, mechanical losses, load characteristics of power

and fuel consumption at constant crankshaft speeds, as well as for given laws of frequency and load changes.

2. Power and torque limits

engine when changing the parameters and adjustments of the power system

niya, gas distribution, ignition and factory tolerances for their

cooking.

3. Detonation characteristics.

4. Reliability, including non-failure operation, wear resistance.

5. Toxicity and smoke.

6. Noise and vibration.

When testing on a stand with an electric drive of reverse action, it is possible to evaluate the operation of the engine in forced idling modes, determine mechanical losses in it, start without a starter, and carry out cold running-in after assembly.

Bench tests of transmissions, in addition to functional testing, include the determination of static strength, stiffness, durability, internal energy losses, noise and vibration, temperature characteristics, special indicators of the operation of units and assemblies. In most cases, tests are carried out on universal stands to evaluate several indicators simultaneously. For testing individual units and transmission mechanisms, direct loading stands (with an open power flow), with a closed loop, with a dynamic load, with a load from the flywheel masses are used.

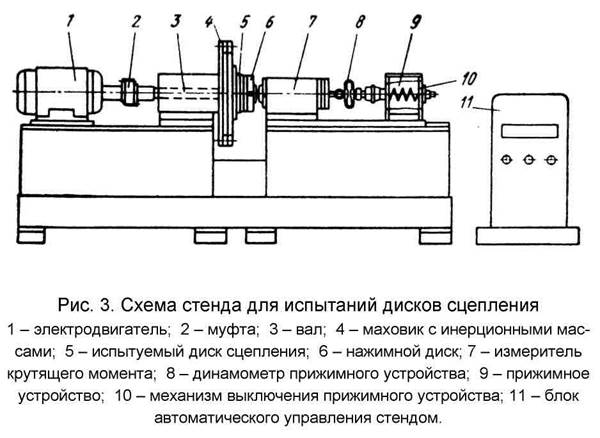

Clutch tests include determining the moment of friction, the reliability coefficient at elevated speeds

friction linings, heat resistance of friction linings, balancing research, torsional vibration damper characteristics, reliability of switching mechanisms, pressure springs, wear resistance of friction linings, their wetness in water and oil, and some other properties. Programs complex tests provide for the cyclic repetition of the processes of engaging and disengaging clutches with different modes on the test bench (Fig. 3).

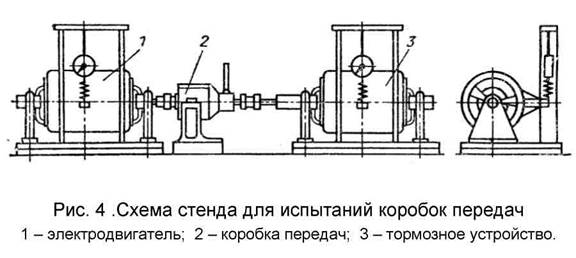

Tests of mechanical gearboxes are carried out on special stands (Fig. 4), are regulated by industry standards or specifications and include: determination of static strength (according to loads that destroy the weakest link), establishing the size and position of the contact spots of the gear teeth of all gears under load, building a temperature characteristic (based on the time of continuous operation at maximum engine power), assessing the level of vibration and noise, the quality of the synchronizers and the control mechanism, and the efficiency factor (COP).

When testing the reliability of gearboxes, the durability of gears is determined (by bending and contact fatigue of the teeth), rolling bearings (by contact fatigue and wear), plain bearings, gear couplings (synchronizers, end surfaces of gear teeth), oil seals, gearbox housing. The influence of various design and technological factors on the operation of the gearbox and its mechanisms is investigated.

When testing automatic transmissions, the following are additionally investigated: the dependence of the switching moment on the speed of the machine and the load on the driven shaft, the characteristics of control systems, friction moments in the brakes and clutches of the box.

Bench tests of cardan gears (Fig. 5) begin with determining the strength under a static load with a torque until the weak link is destroyed. Then vibrations are studied and balancing is performed during dynamic tests on special stands. The critical speed before the appearance of bending vibrations, as well as the transmission efficiency, is estimated. When testing the durability of the driveline, the load change is programmed in four parameters: torque, speed, angle between the shafts, axial movement in the spline connection.

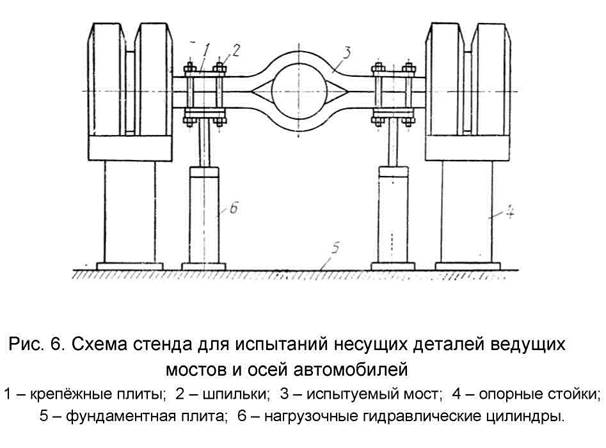

Drive axles are tested on assembled stands and, element by element, their main components: main gear, differential, axle shafts, beam, steering knuckles (controlled drive axles of all-wheel drive vehicles). Methodically testing drive axles are similar

with transmission testing. When testing the static strength and stiffness of the driving axles, the loading scheme is observed, corresponding to the application of vertical loads from the springs (Fig. 6) or the carrier system (with a springless suspension).

During dynamic tests, the efficiency of the drive axle, the differential lock coefficient, the durability of the gear teeth of the final drive, bearings, differential parts, oil seals and seals, axle shafts and beams are determined.

The durability of the semi-axes is determined on stands for cyclic sign-variable loading with torque according to programs that include blocks of low- and high-frequency loads with a step change in amplitude.

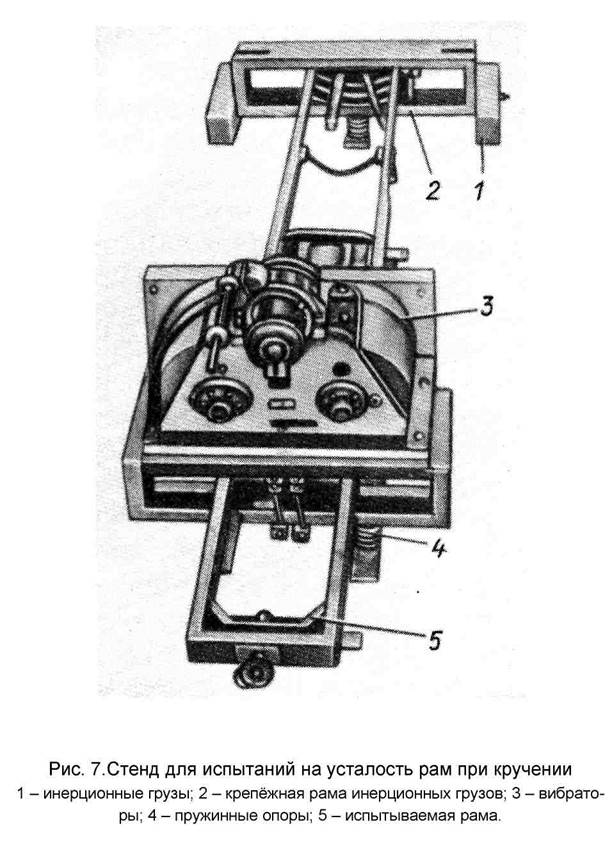

Testing of carrier systems, frames, bodies and cabs are carried out on stands (Fig. 7) of static and dynamic loading separately or together in various configurations, as well as on a machine installed on the stand.

The purpose of static testing of load bearing systems is to test strength and stiffness. At the same time, weakened or overloaded sections and connections are revealed, deformations under the action of

tanavlivaemy units and cargo, various types of external loading. Mostly during testing, two types of loading are used:

Bending in the vertical direction under the action of forces applied in places of real impact (spring supports, engine, cab, body and other units) with overload, for example, for cars 2 ... 2.5 times, for trucks - 2 ,5…4 times;

Twisting with a torque corresponding to the maximum misalignment when overcoming extreme obstacles, for example, corresponding to hanging one of the car's wheels.

The stresses in any section of the structural elements during these tests should not exceed the yield strength of the material, and the deformations should not exceed the permissible values to maintain gaps between the load-bearing elements, in door and window openings, other shape indicators and tolerances for geometric dimensions provided for by the design technological documentation.

An important task of static bench tests is to study the stress state of all elements of the carrier system under load by, for example, strain gauges at many points, the results of which serve as the basis for a significant correlation.

reduction of measurement volumes during subsequent dynamic tests.

On stands with dynamic loading (Fig. 8), the durability of the structure as a whole (frames, bodies, cabs), their parts (for example, frame spars) and individual units is evaluated.

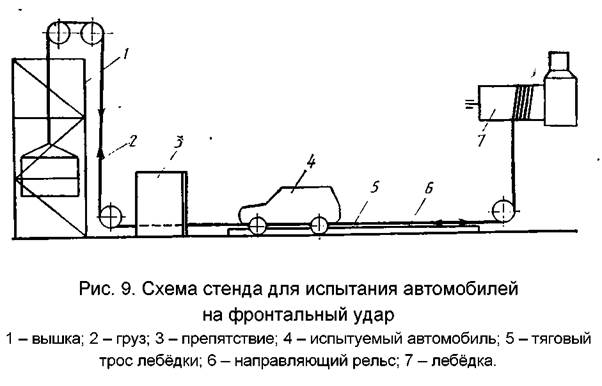

Dynamic bench tests of bodies, cabs and complete machines are the main way to assess passive safety. In this case, rollovers, frontal collisions, rear or side impacts are simulated. Stands are used that accelerate the test object and hit it at a given speed on a massive obstacle (Fig. 9) at different angles (catapult stands), as well as stands with a massive pendulum (co-test stands) for impact loads in certain places constructions. For example, a frontal impact on the upper corner of the cab simulates a car falling off a slope, a side impact on the upper corner of the cab simulates the vehicle tipping over into a ditch, and a rear wall impact simulates the impact of an unsecured load during a sudden stop. By similar methods, power frames of bodies, bumpers, plumage are tested on stands.

Dynamic local loading is also used in separate sections of the structure with the help of various directional vibrators to assess the frequency of natural oscillations and frequency resonances of individual parts and joints.

Suspension bench tests include the determination of the characteristics of elasticity in vertical and transverse-angular deformations. Tests of individual elements and parts also include an assessment of reliability.

Studies of suspension elasticity with torsion bars, leaf springs and springs (as a whole and element by element) are usually limited to static load calibration.

Pneumatic and hydropneumatic springs are tested on stands both under quasi-static (slow) compression at different initial pressures of the elastic medium, and in the mode of dynamic loading according to the harmonic law with different frequencies.

Shock absorbers are tested on stands to determine the dependence of the developed resistance force on the speed of the piston. During control and acceptance tests of shock absorbers, tightness, noise, and smooth operation are determined. The stability of the working diagram is also checked and evaluates -

The dependence of the absorbed energy during the compression and rebound cycle on the temperature of the filling fluid is shown.

Bench tests of durability, as a rule, are carried out element by element: tests of springs, parts of guide devices (hinges, brackets, fasteners), shock absorbers under dynamic loading according to various programs. Sets of mating assemblies are also tested, for example, leaf springs together with hinges and brackets for attaching to the frame. Bench tests with simultaneous bending and torsion loading are also gaining popularity.

Tire testing on the stands are carried out to determine the geometric parameters (radii of free, static, dynamic rolling, the area of contact with the supporting surface along the projections of the tread pattern, along the contour of the imprint), the characteristics of elasticity and damping when loaded with normal, lateral and circumferential forces, the characteristics of the lateral slip, grip properties, durability (mainly in terms of tread wear and carcass delamination).

Rolling modes are predominant in bench tests of tires, mainly on the outer surfaces of rotating support drums. The stands also examine temperature conditions, pressure diagrams and other indicators of tire work processes. The characteristics of elasticity and damping are determined on stands in the modes of quasi-static and dynamic loading.

Mass tire tests are carried out on tire-rolling machines of various designs, on which the onset of limit states is significantly accelerated.

Wheels and hubs on the stands are tested for strength under the action of vertical and lateral forces. Under the influence of the same forces, the wheels are tested for fatigue. In this case, the wheels are mounted on the stands (Fig. 10) motionless, which makes it possible to observe the incipient deformations and cracks.

Steering it is tested on stands mainly for the reliability of steering mechanisms, as well as pumps, power cylinders of amplifiers, wear resistance of hinges and other parts.

During bench tests of steering mechanisms, an external load is applied to the bipod through load devices of various designs.

Friction losses, the efficiency of the steering mechanism, and the characteristics of the elasticity of the steering gear are also studied on the stands.

Brake mechanisms are tested on special stands in order to determine the reliability of their work and resource. Installation of flywheel masses on the shaft of the stand (Fig. 11), corresponding to the simulated weight of the car, which falls on one tested mechanism during braking, allows you to determine the parameters of the brake mechanism in conditions as close as possible to real ones.

Bench tests of complete vehicles carried out mainly for research purposes, based on the principles of movement in the "propulsion - bearing surface" system. In this case, rotating round rollers (drums) serve as the supporting surface.