One of the most important systems in any home is the ventilation system. Not only the convenience of living depends on it, but also the health of people. With the help of this structure, exhaust air is removed from the room and fresh air is supplied. Additional safety is provided by installing a ventilation system in the kitchen. In the kitchen, the hood is simply irreplaceable for removing smoke, unpleasant odors and burning. It is installed above the stove, and unnecessary odors are removed into the general ventilation system of the house.

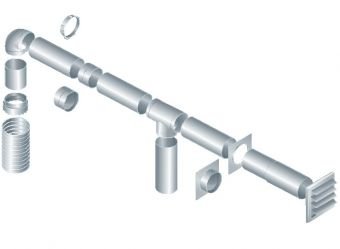

Nowadays, in the household markets, you can find a wide range of various models of hoods, differing from each other not only in external characteristics, but also in functionality, device and dimensions. It is not very difficult to install the ventilation system on your own, but what to do if the stove is installed in one place, and the exhaust duct is located much further? The way out of this situation is quite simple - you need to resort to using pipes for hoods, which are made of corrugated metal or plastic.

As a rule, these structures are characterized by good flexibility and low weight. Installing these pipes with your own hands is also not difficult, since there is no need to use a set of special skills or expensive tools. In order for everything to be as clear as possible, we will first describe the principle of operation of the duct and characterize the different types of pipes.

Air duct device

Hoods can have fundamentally different designs; the air flow is removed through a special ventilation valve or through special holes in the walls. In private houses, the exhaust system is installed after the end of the planning, therefore the diameter of the exhaust pipe is known in advance, it only needs to be measured.

In apartment buildings, finding a solution to the problem of installing a ventilation system is a little more difficult. In this case, the stove and the hood, which should be located above it, are located at a considerable distance from the exhaust hole, and the diameter of the pipe and the dimensions of the outlet hole may be different.

In this case, special pipes and adapters are used, with which you can tightly and tightly connect the pipe to the wall surface and reduce the likelihood of breakage. It is not recommended to install the hob and exhaust system in the opposite direction from the ventilation opening. The presence of a large number of bends, called knees, leads to a significant decrease in the efficiency of the system and can increase the noise level of the device in the on position, which clearly does not add comfort.

Try to avoid such maneuvers

Kitchen hood ventilation pipe

Now, when installing hoods, a variety of types of pipes are used, designed specifically for these purposes. The most popular are corrugated plastic products, as this material is lightweight and does not require the use of a knee when installing this system. These pipes have a long service life and do not require cleaning. At the same time, plastic pipes are smooth and quite rigid.

During installation, you need to use additional tools, such as a special adapter for attaching to the general ventilation system and a knee. Plastic pipes have a pleasant appearance, long service life and do not require additional maintenance. Metal exhaust pipes are made of semi-rigid aluminum, have a corrugated shape, are reliable and simple. When installing aluminum exhaust pipes, a bend is also not required, since the material bends perfectly without changing its properties.

Now let's look at these types of pipes in more detail.

Exhaust pipes made of plastic

Plastic chimney pipes are available on the market in two variations: corrugated and smooth. They have a round or square cross section. Air ducts with a square shape have a more attractive appearance, but the characteristics of a relatively round one are almost the same. During installation, plastic pipes are installed over kitchen cabinets or shelves that hide the air duct. Now you can purchase special designs of built-in exhaust systems that look attractive and neat.

When installing a plastic air duct, the following conditions must be observed:

- The presence of L-shaped adapters (at least three copies).

- The presence of a transition element from the hood to the general ventilation channel.

- The presence of a sealant to seal all joints and provide fasteners.

Pipe diameter for exhaust system calculated based on the size of the ventilation duct, system power and exhaust outlet.

Plastic pipes differ from metal pipes several advantages thanks to which they have become so popular lately. Firstly, the plastic system makes much less noise during the operation of the hood compared to aluminum air ducts. Secondly, smooth plastic pipes do not have cracks in which dirt, grease and the like could gradually accumulate. Corrugated plastic air ducts are also distinguished by this quality, because the polymer surface itself does not allow fat deposits to accumulate on it, but still they are inferior to square smooth pipes.

In addition, plastic pipes with a high quality level are much cheaper. They can serve without complaints for more than ten years, without requiring cleaning or replacement, are easy to install without causing unnecessary stress on the structure, and are hardly noticeable, as they are made of materials of light shades.

Corrugated aluminum pipes

When choosing corrugated aluminum air ducts, it is necessary to correctly calculate not only the length, but also the diameter of the pipe. When installing this system, it is necessary to stretch the pipe as much as possible, this should be done, because such an air duct in its normal state has a lot of folds, which increases the noise of the hood during operation and causes discomfort.

The advantages of using corrugated aluminum systems are easy installation, no need to purchase additional adapters, since corrugated plastic and aluminum pipes bend perfectly initially, they do not need to be cut into pieces and connected at different angles. This quality assumes a more profitable installation, you just need to purchase an adapter for the ventilation hole and from the exhaust system itself.

Aluminum air ducts are made of a semi-rigid material that does not break during installation. It has a high level of strength, but it should be cleaned regularly to remove dirt and grease. The diameter of the pipe must match the diameter of the exhaust equipment outlet and the ventilation duct.

How to correctly determine the pipe design and diameter

When installing an exhaust system at home, you need to correctly choose not only the design and type of pipe itself, but also its dimensions. If during installation it turns out that the pipe diameter is smaller than the outlet of the system, then such unpleasant situations as a significant increase in the noise level and an increase in the load on the exhaust device may arise. All this together, sooner or later will lead to breakdown and the need for expensive repairs. If the hood was purchased assembled in a store, then you can install the exhaust equipment yourself, which will save a considerable amount.

The air duct should not be long, as this greatly decreases the efficiency of work, and each turn at right angles reduces the power level of the system by about one-tenth. If the rotation angle of 90 degrees is exceeded, the outflow of air will not occur correctly and will cause overloading of the exhaust system. This often happens when square pipes are installed.

There are two types of such valves: membrane or with a plastic disc. The optimal size of any duct is up to three meters; with a longer length, a drop in performance is observed. In this case, it is better to choose smooth-walled pipes with a round cross-section.

Features of installing a ventilation system in the kitchen

During installation, air ducts can be masked using various methods, and the most popular of them is the use of a decorative box, through which access to the pipes is quite simple. If necessary, ventilation pipes can be laid above the surface of the false ceiling or embedded systems located inside the kitchen set and invisible from the outside. When installing an exhaust system, it is worth adhering to several safety rules, which are regulated by such regulatory documents as GOST, SNiP and OST.

When installing a ventilation system, not only the size of the pipe is of great importance, but also how it will be brought to the hole. Do not completely close the passage to the ventilation duct, otherwise the air exchange inside the room will be disrupted. In this situation, it is better to use special adapters.

When installing the duct, make sure that there are no sagging sags on it. If you are using an aluminum corrugated pipe, stretch it as far as possible.

Do not forget about electrical safety, grease and dirt often get inside the system, moisture accumulates.

If the hood is not properly connected to the mains, there is a risk of electric shock. The hood is connected to the power supply using three wires: ground, phase and zero. The standard ground wire is yellow with a green stripe. Before installation, you need to take care of the grounding for the safe use of the electrical appliance.

If the house already has a grounding loop and European-type sockets are installed, then there should be no problems: when connecting, the wire is connected to the grounding terminal, indicated by strips of different lengths. If the equipment does not have a special connector for grounding, you can make it yourself by screwing a wire to the metal case. In the event that you do not have euro sockets, you can do zeroing yourself, but it is strictly forbidden to connect it to pipes and batteries, it is better to do this to a dead neutral.

The rest of the steps must be performed in accordance with the instructions that will be attached along with the exhaust equipment.

This is the whole process of installing ventilation in the kitchen. Now you have fully learned all the necessary information about the significance of this system and can carry out the work on its installation yourself.

2868 0 0

Secret passage for 007 agent or ventilation pipes

30 July, 2016

Specialization: Capital construction works (foundation laying, wall construction, roof construction, etc.). Internal construction work (laying of internal communications, rough and final finishing). Hobbies: mobile communications, high technologies, computer technology, programming.

Each of you has seen metal pipes for ventilation. If not in reality, then at least on TV. After all, it is they who are used by the employees of the secret services to penetrate specially protected objects.

However, as you can imagine, the main purpose of the ventilation ducts is different. They are designed to remove heated and polluted air from the premises and deliver clean air there from the street. Many people underestimate the importance of this engineering system, and then suffer from high humidity, stuffiness, unpleasant odors and so on.

This could have happened in my client's private house, which is now being built in one of the cottage villages outside the city, the owner of which did not want to install ventilation ducts in the dwelling. He said that one pipe will be enough for him, which will ventilate the toilet. Fortunately, I was able to convince him otherwise.

Now I have to buy and install pipes for the ventilation system of the cottage. But at the same time, there was a reason to tell you about what products are used for arranging air ducts. This is in case you are going to do ventilation with your own hands.

Features of installation and operation of ventilation ducts

The instruction for the construction of any building provides for the presence of a ventilation duct (or several) in it. Usually it is part of the structure of the house and is set up 10-15 cm from the chimney in order to improve the efficiency of air outflow. An exhaust vent is usually installed in order to prevent unpleasant odors from floating around the house.

However, if you want to provide yourself with a really comfortable microclimate, characterized by normal humidity and temperature, I recommend that you provide ventilation throughout the cottage. This is what air ducts are for. Taking air in different parts of the building, they deliver it to the central channel, through which it is removed to the street.

The ducts for transporting air can be laid out of bricks or cast from concrete, making them part of the structure. However, this method is very time consuming. That is why I personally recommend using finished products for this. These can be PVC pipes for ventilation or metal ventilation ducts (galvanized or stainless steel).

Plastic parts for the installation of air ducts are great for the construction of private residential buildings, and I often put metal parts in the construction of offices, commercial buildings, I saw in production workshops. Although recently and in the listed cases, polyvinyl chloride or polypropylene are more used.

So that you do not accuse me of bias, I will tell you about all types of pipes. Moreover, they can be combined in most ventilation systems.

Plastic pipes for ventilation ducts

Personally, when choosing between plastic and metal, I still prefer the former. These air ducts are the best suited for air transportation due to their performance properties and have a very long service life (guaranteed up to 50 years).

Well, most of all I am attracted by the price. To purchase the required amount of materials, regardless of the amount of work, you will have to spend much less money. This, of course, cannot but rejoice. Especially when you are building a house with your own money.

However, I will dwell a little more on technical characteristics products.

Purpose and varieties

Plastic pipes for the arrangement of ventilation, as I already mentioned, they can be used for domestic and industrial purposes. They are often used in apartments to connect the hood above the stove to a vertical air duct. And in large private houses, I advise you to mount them in such a way as to ensure ventilation of all rooms without exception.

For ventilation to work effectively, it is necessary to ensure not only the removal of polluted air, but also the flow of clean air. If during the construction you used modern materials that prevent air infiltration, I advise you to additionally install supply valves above window frames or under window sills. Although you can go even further and make supply and exhaust ventilation.

Currently, there are the following types of pipes:

- Rectangular... The sizes of PVC or polypropylene air ducts can be different and depend on the required power (throughput) of the ventilation system. I often use such products for open laying, as they look more aesthetically pleasing.

- Round.These air channels have an optimal, from the point of view of physics, section, therefore they work more efficiently. The air flow, moving through the pipe, meets less resistance. This factor is usually taken into account when choosing the capacity of ventilation equipment.

Both those and other parts are easily assembled into a finished system using shaped parts. Ventilation pipe clamps are used to secure the air ducts to walls or ceilings. Since all products are small, there is no need for reliable and powerful fasteners.

Advantages and disadvantages

You already understood that I am a little biased towards the choice of ventilation ducts, preferring plastic ones to metal ones. However, in order not to be unfounded and to justify my choice, I will tell you about the main advantages of these products:

- Resistant to corrosion.Plastic, unlike metal, is absolutely not subject to corrosion, which significantly increases its service life. Of course, stainless steel can also boast of this, but its cost is much higher.

- Ease of installation.Due to the low weight and a large number of fittings, the installation process will not be difficult even for an inexperienced craftsman.

It is enough to simply design an air duct of the desired configuration using angles, tees, crosses, and so on. And the fixing is done with brackets, which are driven into the wall on dowels.

To reduce the noise that air channels create when air moves through them, I recommend buying brackets with a seal that absorbs the generated vibrations.

- Strength.Although the strength characteristics of plastic are inferior to metal, air channels made of polypropylene or PVC can withstand significant mechanical stress without any problems. And if you lay them secretly, then, in general, you will not have to think about it.

- A large assortment. Modern manufacturers produce such a wide range of plastic pipes that they can be used for almost any task.

- Smooth inner surface.Polymer pipes have no roughness inside, so the air flow passing through them does not encounter obstacles and does not create turbulence. Therefore ventilation can be equipped with less powerful fans.

Summarizing all the pros and cons, I personally want to note that plastic ventilation pipes have the best ratio of affordable price and high quality. They are ideal for the construction of ventilation ducts.

If you decide to choose this option for your own construction, then you will undoubtedly need information about the sizes of such parts and the price for them.

Dimensions and cost

GOST provides that ventilation pipes can have a diameter of 10 to 200 cm. However, when building a house, there is no need to use such more air ducts. Most often, in my practice, the following varieties were enough for me:

- rectangular air ducts - with a section of 110 by 55, 120 by 60 and 204 by 60 mm;

- round air ducts - 100, 125 and 150 mm in diameter.

The specific dimensions depend on the required performance of the ventilation system. Before calculating the diameter of the pipes, you need to know the area of \u200b\u200bthe premises, their purpose, the type of fans and much more.

The average cost of one running meter of a rectangular duct averages 250 rubles, a round one - 160 rubles. They can be freely purchased not only in specialized plumbing stores, but also in large construction supermarkets.

Steel pipes for ventilation ducts

An alternative to plastic pipes for ventilation are metal ventilation ducts, which serve well both in private homes and in commercial premises.

Moreover, I can say with confidence that the proportion of such products in individual construction is falling all the time. The fact is that when compared with polymer ventilation ducts, metal ones have the worst performance characteristics.

Galvanized steel, despite its corrosion resistance, deteriorates faster. Moreover, as soon as rust begins to form in the ventilation pipes, you will immediately feel unpleasant throughout the house.

Of course, air ducts from of stainless steel, which are devoid of this drawback, and look, I must say, excellent. But you yourself understand that the purchase of such materials will be a very tangible blow to the repairs planned for construction.

And one more point worth mentioning. The metal surface creates more resistance to the passing air flow, so you will have to take pipes of a larger diameter and install powerful fans.

In conclusion, I want to note the weight. I have often had to design metal ventilation ducts. They are very heavy, so they are mounted on powerful brackets. And after work the hands just fall off. So think about whether you need it?

And so that you form an objective opinion, I want to talk about the advantages of metal pipes for ventilation. After all, otherwise they would be completely ousted from the market by more progressive plastic products.

- Plastic pipes can have a cross section of up to 2 meters. Although this is more than enough for private construction, industrial premises sometimes require more efficient and efficient ventilation. It is in this case that the metal helps out, from which you can make arbitrarily large channels (agents of different special services are perfectly placed in them).

- Metal, unlike plastic, is much more durable. Although this advantage does not have too much of great importance for private houses, in commercial buildings, this parameter is a priority.

All ventilation ducts mentioned above are classified as rigid. However, to solve some problems, flexible ducts are required, which I will talk about next.

Corrugated pipes

Rigid metal and plastic pipes are used to construct main ducts that transport fresh air from the street or polluted air from rooms.

However, situations often arise when the duct needs to be bent several times before it can be connected to the suction fan or ventilation grill. Or take him through a very narrow place. In this case, a flexible corrugated pipe for ventilation is the best fit, which can take any configuration.

There are two types of such parts:

- Metallic.Made from multilayer corrugated aluminum foil. It can be easily bent at any angle, making ventilation connections to any outlet.

However, I want to note right away that there are folds inside the pipe, which means that they create considerable resistance to the air flow.

- Plastic.It is a part made of a mixture of polyester and aluminum foil. The inside of the plastic pipe is reinforced with steel wire, which is twisted into coils.

Unlike aluminum pipes, plastic pipes have improved thermal insulation and sound-absorbing properties. Therefore, it is them that I use in residential buildings and apartments, when it is necessary to connect a hood or a fan with an already mounted hard plastic duct.

Output

Now you know what parts can be bought and used to install the ventilation system in a private house. If you are interested in ventilation in an apartment (for example, in the kitchen), I recommend watching the video in this article.

Also I would like to ask if you used PVC sewer pipes for the installation of ventilation ducts? And if so, how exactly? You can leave your answers in the comments to the material.

July 30, 2016If you want to express gratitude, add clarification or objection, ask the author something - add a comment or say thank you!

The exhaust pipe can be used in a private house. In this case, it is intended for a gas water heater. Let's consider how to choose and install exhaust pipes for a kitchen or gas boilers.

Constructions for installation in an apartment

There are the following pipes installed for the hood in the kitchen:

- Plastic. They can be square and round. They are aesthetic and high-capacity. Smooth walls help to reduce noise, no dirt accumulating on the walls. Plastic pipes are affordable in terms of cost. Their service life reaches 10 years. During all this time, they do not need maintenance, cleaning. Installation is very easy. For installation, you will need L-type adapters, adapters from the hood, sealant. Plastic structures have different diameters. Which diameter should you choose? The choice depends on the power of the network, the size of the ventilation channel;

- Corrugated. It is usually used when there are difficulties with wiring due to the inability to use several knees. They are great for hard-to-reach locations. They are distinguished by simple installation, no need to purchase adapters, efficiency, durability. Made of aluminum or plastic. When choosing an aluminum pipe, it is important to calculate its optimal diameter. This parameter depends on the size of the outlet of the ventilation and exhaust system. During installation, it is required to stretch it, as folds increase the noise. Among the disadvantages is the need for regular cleaning.

What to choose? If you are willing to sacrifice low noise for ease of installation and design, go for corrugated products. If high throughput is important to you, buy plastic structures.

Features of installing structures from different materials

The installation of a pipe in the kitchen depends on the material from which the product for the hood is made. To install plastic structures, adapters are required. If square products are installed, knees are also required.

When installing the hood in the kitchen, it is important to remember the following rules:

- It is recommended to purchase exhaust structures for kitchen hoods when the required diameter and section are determined. All these parameters depend on the dimensions of the ventilation hole and the hood. The dimensions of the product should not be less than the ventilation outlet in the kitchen. Otherwise, this will lead to a decrease in power, a greater load on the system, which can cause an early failure;

- It is impossible to mount exhaust structures in the kitchen so that their angle would exceed 90 degrees. Every large kink negatively affects the performance of the kitchen system. In addition, it leads to incorrect air outflow;

- It is advisable to install check valves to prevent air flow backward.

Compliance with simple rules will allow you to install the structure for the kitchen system so that it will serve you for a long time and will not spoil your mood with breakdowns.

Varieties of designs for heating devices

It is beneficial to install hoods for a gas column for the following reasons:

- They help increase traction;

- They perform the function of removing combustion products.

The standard pipe diameter for a gas water heater is 110 mm and 130 mm. Structures with a diameter of 110 mm are used for a gas water heater with a capacity of not more than 19 kW. Products with a diameter of 130 mm are used for devices in a private house, the power of which is from 21 kW.

Pipes for ventilation installed in a private house are of the following types:

- Corrugated. Among the advantages are reliability, mobility, affordable price. Products for a gas water heater in the house can be stretched up to 3 meters, increased with metal tape. During installation, to give the desired shape and direction, steel wire is used;

- Aluminum. The advantages of such designs for a gas water heater in a private house: resistance to the effects of condensate, low weight, easy installation;

- Steel. The standard length is 1-1.5 meters. If the ventilation system has a horizontal section, bends can be installed at 90 degrees. Advantages: strength, reliability, long service life. Disadvantages: the formation of condensation, the need for insulation in the winter;

- Coaxial. Such pipes are increasingly used in a private house to organize the work of a gas water heater. Advantages: more clean air remains in the house, high productivity. The structure is mounted with a slope of 3 degrees. This is to prevent precipitation from entering the system.

Duct installation rules

Before installing in a private house, it is important to carry out calculations.

The diameter of the structures depends on:

- Gas column capacity;

- Exhaust air volumes at maximum power;

- Differences between outdoor temperature and exhaust air temperature;

- Duct heights.

The height of the structure depends on the type of gas system. Before installation, the place where it is best to install the air duct is determined.

If a private house has a fireplace or other systems with chimneys, it will be convenient to bring an air duct to them. If there is no fireplace, an exit is made, where an asbestos structure with a diameter of 120 mm or more is mounted.

The degree of draft depends on the height of the duct. It is better if the structure is one meter higher than the roof (at least). For safety, the duct is mounted high on the wall in the house. Before installation, holes are made for fastening, then the device is mounted to the wall using self-tapping screws. It is possible to perform 90 degree turns. They are performed with the help of knees. However, this reduces thrust.

Ventilation pipes designed for hoods are produced in an assortment, and therefore you will definitely be able to buy the desired option. The correct choice of ventilation structures and quality installation have a positive effect on both the performance and the long service life of the system.

A ventilation pipe in a private house provides air exchange necessary for health, helps to remove dust, vapors of harmful substances and excess moisture. What ventilation systems are most in demand, and what you need to remember when installing them - learn from this article.

Types of ventilation systems

Ventilation pipe to the roof.

Plants for air circulation differ in design features (they are divided into type-setting or monoblock), by purpose (there are exhaust or supply), by the size of the serviced area (they are general exchange or local), by the method of air movement (natural or artificial).

- Supply air. The system heats the air in winter and cools it in summer.

- Exhaust. Removes exhaust air.

- Local. Delivers fresh air to a specific location or removes a gaseous air mixture from a specific area of \u200b\u200bthe room (for example, kitchen hoods).

- The type-setting ventilation system is often located behind a false ceiling. Includes fan, filter, silencer, automation system. It needs a professional calculation, it has large dimensions.

- The monoblock system is a sound-insulated box in which all ventilation units are enclosed. The built-in recuperator saves heat and energy. Such a system is not only more expensive than the previous one, it also needs more pipes.

Design rules

The transition of the pipe from one diameter to another should be smooth.

Fresh air flows should first of all be directed to the living room, nursery and bedroom, then to the corridor, kitchen and bathroom.

When choosing a ventilation system, you need to know the height of the ceiling and the area of \u200b\u200bthe apartment. Multiply these values \u200b\u200bto get the supply ventilation capacity. For a 2-room apartment, this parameter should be within 200-300 m3 / h, for a 3-room and 4-room apartment - 500 m3 / h.

In bathrooms, kitchens, in rooms with a fireplace, there must be an exhaust pipe for ventilation. In a private house and in an apartment building, channel-type systems are being built. The main requirements for them: compliance of the pipe diameter with the flow of passing air, fire safety and tightness.

The air flow is distributed to the rooms with a ventilation pipe. In a private house, as in a production room, the air flow rate is the main parameter by which the diameter of the inlet and outlet pipes is selected.

Ventilation system device

Principle of operation

Duct system - a set of components for forced ventilation.

Through the hood, air is drawn into the roof deflector. With the help of the supply air intake, air is returned to the room.

The recuperator of the heat exchanger forces the heated air to give its heat to the incoming cold air, thus saving 25% of thermal energy.

Advantages: removal of harmful impurities using a filter, heat saving, cooling (heating), dehumidification (humidification) of the air.

Disadvantages: the system automatically turns off in the absence of electricity, noise during operation, the complexity of the control unit (sometimes there is a need for maintenance).

It is important! Supply ventilation in a private house from sewer pipes better not to mount. The material may contain toxic substances that will enter the room along with the air. For a chimney, this option is fine.

Installation takes place in this order:

- Calculation of air exchange.

- Selection of pipe cross-section.

- Selection of the type of ventilation system.

- Drawing up a ventilation scheme (establish the places of intake and exhaust of air and places of pipe laying).

When laying the system, try to avoid right angles and abrupt transitions of pipes with different diameters.

Plastic pipes do not rust, are easy to install, have an aesthetic appearance and low weight, and create less noise during operation (in comparison with metal ones). But the fire resistance of plastic is low.

For residential premises, it is optimal to use a corrugated flexible pipe made of polyester and aluminum foil. It has increased thermal insulation and sound absorption.

It is best to take care of the air ducts at the design stage of the house. Each room should have a separate pipe, they should all converge into one channel.

If an air filter is installed at the inlet of the system, it will retain about 80% of the dust.

Install a silencer at the outlet of the air handling unit - and your pipes will not remind of themselves during operation. The control panel, filter clogging control function, the ability to connect to the “Smart Home” system - all this makes the ventilation unit really convenient.

The air duct system is installed before finishing repair work.

Warming of air ducts

The ventilation system becomes clogged with dust over time. A filter to clean the incoming air will help to cope with the problem.

Insulation protects against mold, allows you to increase noise insulation by reducing the vibration of the air moving through the channels, reduces heat loss. Many heaters have fire-fighting properties (prevent the spread of fire).

So, let's determine how and what to insulate ventilation pipe in a private house.

Polyurethane foam

The shell made of polyurethane foam is resistant to mechanical damage, does not absorb moisture, does not burn, keeps heat well and can be used after disassembling the structure.

The PPU shell consists of two halves that cover the pipe. The material has high thermal insulation properties, over time does not lose its original shape, does not crumble, does not emit harmful substances, has a more affordable price compared to mineral wool. Retains thermal insulation functions for 25 years. You can choose a shell for any pipe diameter.

There is only one drawback - the fragility of the material.

The order of work is as follows:

- The insulation is fixed with construction glue or aluminum tape.

- Before starting work, the pipe is treated with an anti-corrosion compound. - - After that, the half-cylinders are fixed with polymer or metal fasteners and mounting tape.

- Insulation elements are overlapped (5-10 cm). The component parts of the shells are connected by the “thorn-groove” method, in the case of a small diameter - “steps”.

Mineral wool

It is cheap and non-flammable material. But during the installation process, you need to use construction goggles and a respirator (the smallest particles of insulation should not get into the lungs and eyes). The material absorbs moisture - it must be wrapped in foil or galvanized. The main disadvantage is that the cotton wool cakes over time.

The airtightness of the plastic windows and the sealing of the internal doors for soundproofing disrupt the air exchange in the house. Ventilation ducts installed in the kitchen and in the bathroom for natural air circulation may not cope with their function. Experts recommend using a supply and exhaust system with heat recovery. Additionally, air conditioning, humidification, air ionization can be carried out. All this will help create a favorable microclimate.

Video: ventilation in a country house.