In the market, everyone can choose heating registers for installation in an apartment or a private house. On sale there are structures made of metal horizontally arranged pipes interconnected by special jumpers, due to which the water moves through the heating device. Modern registers have higher heat dissipation than traditional Soviet batteries. The most popular aluminum registers have the best specifications. Homemade batteries are used in small apartments or rooms, ensuring proper heating of the available space.

Types of registers for installation

The most commonly used products are cast iron, steel and aluminum. The most common aluminum. Their advantages are as follows:

- resistant to corrosion;

- have a minimum weight;

- long term of use;

- no joints and joints from welding;

- high heat dissipation.

In the manufacture of aluminum registers, cast casting is used. Install such products most often in residential and office premises. If you need heating at the factory, it is better to set the registers made of steel or cast iron, as they are more durable. Heating systems can be either stationary, in which the heat carrier is heated by a boiler, or mobile. Such registers have special protection against accidental electric shock. Steel heating registers are not characterized by high heat dissipation, but they significantly benefit from the budget cost, ease of processing and a large selection of sizes.

Stainless steel registers are also used, but they have low heat transfer, so many pipes are needed for their manufacture, which is quite expensive. In heating systems, where all the wiring is made of copper pipes, registers of the same material are installed. They have the highest heat dissipation. It is 4 times higher than steel. Copper has high ductility, so it is easy to bend in the right places. Welding is required only at the junction points of different parts. Copper registers have quite significant drawbacks - this is a high cost and the need to comply with the terms of use. In order for the copper registers to last for a long time, the following conditions must be observed:

- in the heat carrier there should not be solid particles;

- should not be in the system and other metals incompatible with copper;

- in order to avoid corrosion in the system, grounding is installed;

- since the metal is very soft, special protection on the registers is needed.

Cast iron registers are massive and heavy, so you need to install strong racks under them. Cast iron is a very brittle metal and can be damaged by a strong blow. Because of this, pig-iron registers need protection in the form of casings, which significantly reduces heat transfer and increases their price. Installing them is quite difficult. Cast iron is a chemically neutral material, and it does not matter what kind of coolant is in the radiator.

The most budgetary and reliable material for registers is steel.

Calculation of registers for premises

Calculation of heating registers is easy to do on your own. To do this, you need to know some features:

- The diameter of the pipes for the registers is up to 32 mm.

- It is not recommended to use pipes with a diameter of more than 82 mm. In this case, the boiler will not be able to supply a sufficient amount of coolant.

For each room and building, you need to calculate the required number of pipes in the register and their diameter.

When calculating, you need to consider several factors:

- number of doors and window openings;

- materials of which doors and windows are made;

- the thickness of the walls in the house.

It is necessary to take into account the heat transfer level of 1 m pipe.

Design features

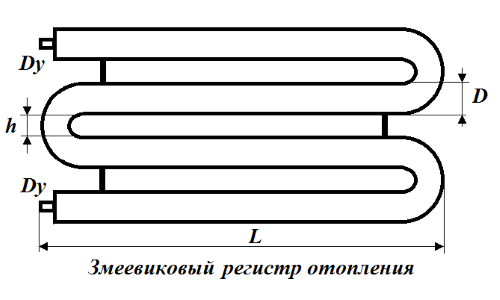

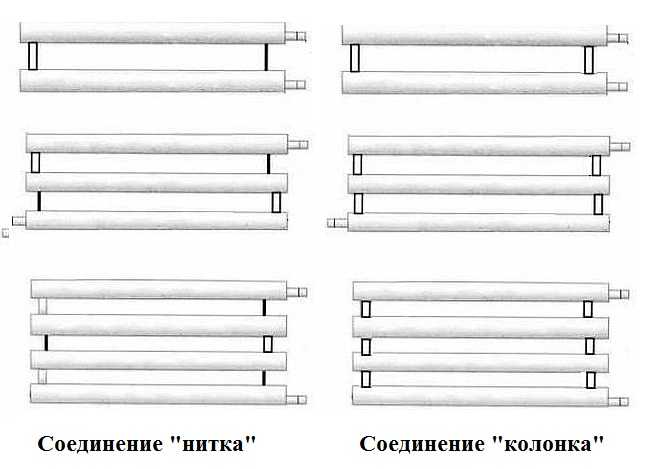

Most often, steel radiators are used. smooth pipes. Welding of smooth pipes is register and serpentine. Register can have 2 types of pipe connections - this is a column and a thread. Column - the connection of each pipe to each other on both sides using jumpers. When connecting the "thread" jumpers are installed alternately, then on one, then on the other hand. This ensures a serial connection, and the coolant flows around all the pipes in turn.

The heater radiator can be welded not only from round, but also from square pipes. They do not differ much, but it is more difficult to work with them and higher hydraulic resistance. Although such radiators are much more compact.

The contact area of \u200b\u200bthe metal with the air in this case is much larger, which increases the heat transfer. Such heating registers do not look very presentable, but they heat the room well, despite the temperature outside the window.

Do-it-yourself installation

It is very simple to set the heating register with your own hands, especially if it is made at the factory. Such registers are made efficiently, but their cost is quite high. It is much more economical to make a heating register yourself, but for this you need to have some tools and materials:

- stubs;

- the required number of pipes;

- air bleeder;

- bends;

- hammer and drill;

- screwdriver;

- oil paint;

- welding machine;

- grinder;

- adjustable and gas keys.

The register scheme is quite simple, but you need to have some skills welding workotherwise manufacturing will be problematic. After all the tools and materials have been prepared, the register form is selected. Usually it is mounted in the form of a coil or in parallel.

Billets of the selected size are cut from the pipes, their inner cavity is cleaned of excess. Plugs are welded to the ends of the pipes, in which holes can be made for connection. Using taps we connect the heating registers, the schemes can be used different. Further mounted on each side of the faucet for periodic descent of excess air. Before assembly, it is recommended to cover the radiator with your own hands with oil paint.

A homemade heating radiator will cost much less. If there is no self-confidence, then it is better to get ready.

The heating register is an integral part of the heating system, a device consisting of several parallel horizontal smooth pipes. This kind of heating devices did not win much popularity among private homeowners and there are objective reasons for this. The register-based heating system has a large volume of coolant, for the heating of which much more energy is required than in the case of conventional radiators.

Application area

Currently, water heating registers are mostly used in factories (workshops, workshops, warehouses, hangars and other buildings with large areas). A large volume of coolant and large dimensions allow registers to effectively heat such rooms.

The use of heating registers in industrial buildings provides the most optimal efficiency of the heating system. Compared to cast iron or, registers are characterized by better hydraulics and heat transfer. The relatively low cost of their manufacture reduces the cost of installing the entire factory heating system. In addition, they are not expensive to operate.

Despite this, the concept of profitability does not apply to this type of heating devices. As noted above, a lot of energy is required to heat a large volume of coolant.

Heating registers at one of the food industry in the Moscow region.

Heating registers from steel electric-welded pipes can be used both in single-pipe and in two-pipe heating systems with forced or gravity circulation of the coolant (based on water or steam).

Note! Due to the large volume of coolant that requires a lot of fuel to be heated, only enterprises can afford the use of heating registers, but not the owners of private houses, for which cost-effectiveness is important heating system.

Benefits

- The large length of the devices (up to 6 m) allows you to evenly and as soon as possible heat the entire area of \u200b\u200bthe room.

- High hydraulic performance.

- Relatively low price. The cost of a mobile 3-pipe device (designed for heating a room with an area of \u200b\u200bup to 200 m²) with steel pipes with a diameter of 108 mm, with a wall thickness of 3.8 mm and a length of 3 m, with a power of 2.5 kW is about 13,000 rubles.

- Simplicity of operation. Devices are easily and quickly cleaned of accumulated dust and other contaminants.

Mayevsky crane at the top of the register.

disadvantages

- A large volume of coolant does not allow the efficient use of registers in private homes. Home boilers simply will not be able to heat such an amount of water or heating will be insufficient.

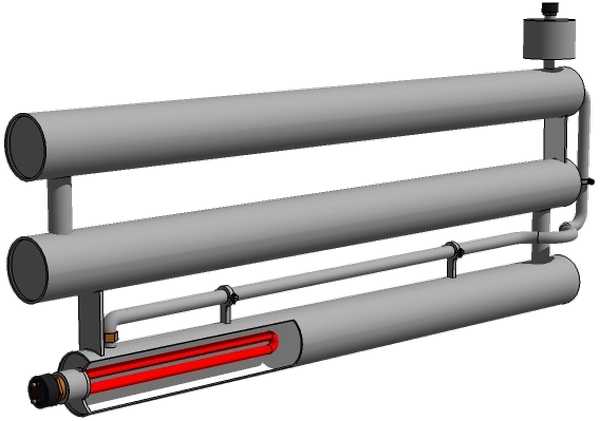

Advice! To increase the power of the entire heating system of a private house, in addition to the boiler, a tubular electric heater can be installed. The heater is mounted in the lower register tube and is an additional source of heat. In the coldest weather, when the boiler does not cope with the heating of the house, you can turn on the heater.

Technical characteristics of heating registers

- Working pressure: 10 atmospheres

- Processing medium (coolant): water, steam.

- Type of connection: threaded, or for welding.

- Heat dissipation: 500-600 W / meter

There are 3 main varieties of registers:

- sectional U-shaped;

- serpentine S-shaped;

- “Mixed” (U-shaped serpentine).

The main elements of heating registers are steel pipes (or pipes from of stainless steel grade 304) with a diameter of 25 to 200 mm. Registers with a diameter of 25 to 100 mm are used for heating factory premises for administrative or business purposes, devices with a diameter of 100 to 200 mm are used in production shops or large sports complexes (pools, volleyball, basketball halls).

As for private households, the use of registers is one of the most inefficient ways to heat a private house.

2-pipe register.

The number of sections of the device can be unlimited and depends only on the area of \u200b\u200bthe room and the required heat transfer.

Advice! Applying too many pipes (more than 4) will still fail to significantly increase the power of the entire device, because the ascending warm air heated by the lower pipes will be less able to receive thermal energy from the upper pipes.

Production of heating registers

For the production of heating registers, steel pipes of various diameters (25-200 mm) are used, which are welded together at a distance of 50 mm from each other (reducing the distance between the pipes can lead to a decrease in heat transfer). Such a distance allows to achieve maximum heat transfer and minimize mutual radiation.

The register includes supply and return, as well as an air vent installed in the upper part of the device with a ball valve. The nozzles on the supply and return can be made in two versions:

- Threaded connection;

- Connection for welding.

When ordering registers individually at the factory, the registers can be delivered either ready-made, assembled or disassembled, which saves money on logistics.

How to make a heating register with your own hands?

Unlike other heating appliances, for the production of which complex, expensive equipment is required, water heating registers can be made by yourself. The main things that are required for the manufacture are smooth steel pipes and the ability to use a welding machine. If you cook it yourself, you get the cheapest option, but if you have to invite a third-party welder to conduct welding, such a register may be more expensive than the factory one. In this case, you should consider whether it is worth doing it yourself or is it easier to buy a factory device.

So, if the registers are made for use in a private house, you will need the following tools and materials:

- Steel pipes with a diameter of 25 to 100 mm, or profile pipes similar size;

- Jumpers made of steel pipe with a diameter of 25-32 mm;

- Plugs for pipes;

- Inlet and outlet nozzles for welding or threaded connection;

- Branch pipe for the air vent with a ball valve;

- Fasteners (brackets for wall mounting, or floor stands);

- Welding machine;

- Electrodes

- Welder personal protective equipment (mask, gloves).

- Gas key;

- Angle grinder;

- Centimeter;

- Building level;

Important! If the heating register is from steel pipes acts as an autonomous heating system for a separate room, when the heat source is a heater built into the device, then in this case a mandatory one is necessary.

After the completion of welding work and the connection of accessories (etc.), the register is crimped under pressure. If no leak is detected, the appliance is painted. If a leak is detected, the coolant is drained, and the problem area is again brewed.

How to improve register efficiency?

The registers have a relatively small heat transfer surface, and metal plates that are vertically welded to the pipes can be used to increase it. The result is a kind of ribbed pipe.

In addition, the registers can be improved in such a way that they will “give out” convection heating. To do this, instead of metal plates, round or profile pipes are vertically welded to the front of the device, which will create a convection effect. Convection is based on the fact that hot air always rises. Cool air, located in the area of \u200b\u200bthe floor, is drawn in through the lower part of the pipe and warmed up, rises. Passing through the pipe, the air heats up and exits already warmed up through the upper part of the pipe.

Turning to us, be sure that any product will be cheaper with us than in any metal, as we have been specializing in heating registers for many years and work at wholesale prices of a major supplier pipes at the federal level.

Price list for heating registers

The cost of 1 row, 1 m.p. finished product without painting

12.12.2016

In connection with the rise in price of iron, the cost has slightly increased!

| Title | Pipe mm | a type | Price r / m |

| Heating register | 48x3 | serpentine | 390 |

| Heating register | 48x3 | sectional | 370 |

| Heating register | 57x3.5 | serpentine | 470 |

| Heating register | 57x3.5 | sectional | 440 |

| Heating register | 76x3.5 | serpentine | 570 |

| Heating register | 76x3.5 | sectional | 550 |

| Heating register | 89x3.5 | serpentine | 610 |

| Heating register | 89x3.5 | sectional | 570 |

| Heating register | 108x4 | serpentine | 730 |

| Heating register | 108x4 | sectional | 650 |

| Heating register | 114x4 | serpentine | 810 |

| Heating register | 114x4 | sectional | 750 |

| Heating register | 133x4 | serpentine | 950 |

| Heating register | 133x4 | sectional | 850 |

| Heating register | 159x4.5 | serpentine | 1250 |

| Heating register | 159x4.5 | sectional | 1150 |

| Heating register | 219x5 | serpentine | 2150 |

| Heating register | 219x5 | sectional | 1850 |

- Water, Ethylene, Propylene Glycol

Test pressure

16 bar (1.5 MPa)

Operating pressure

from 0.1 to 11 bar (1 MPa)

External diameter

pipe (mm)

Area

heating (m²)

Registers are most often called heating radiators made of metal pipes. The advantage of registers over standard heating radiators is that they can be made according to the size of the room that needs to be heated.

The production company "Svarnoy" offers ready-made registers consisting of several pipes interconnected by hollow jumpers (the coolant runs through the entire structure thanks to these jumpers). Such registers are used in industry and agriculture - for heating industrial premises, in sports - heating gyms, education - they are used for heating basements and gyms of schools. It is possible to use such registers in private homes as well as garages.

Ready-made registers are also available that have a c-shaped connection, which is created from a bent pipe with a diameter similar to the main pipes of the register. Such registers are most often used for heating industrial premises of a large area.

In addition to the ready-made registers, the specialists of the Svarnoy production company are ready to make these heating appliances in the dimensions required by the customer, or for a specific room.

An individual connection is also made to connect the register to the heating network. This connection can be threaded, flanged or prepared for welding.

It is possible to color the registers in color, required by the customer. The inner surface of the pipes also undergoes anti-corrosion treatment.

Additionally, the registers can be equipped with brackets for positioning them along the walls and similar devices for the floor arrangement of registers.

smooth heating registers, manufacturing of heating registers, production of registers

heating, pipe heating register, price heating registers, smooth pipe heating registers,

heating registers from steel pipes, heating registers Moscow, steel heating register

There are a considerable number of different kinds of heating devices on the market. However, home-made radiators are still used. And the most common are registers from pipes. Heating registers - welded or prefabricated structures from horizontally arranged pipes interconnected by jumpers for circulation of the coolant.

What are

Heating registers are made of different materials, they have different shapes. Each has its pros and cons.

What are they made of

If we talk about materials, the most common is steel, or rather steel, electric-welded pipes. Steel has not the best heat dissipation, but this is offset by a low price, ease of processing, affordability and a large selection of sizes.

Very rare are made from stainless pipe - decent power requires a large number of pipes, and how much stainless steel products cost, you have an idea. If they did them, then probably for a long time. They also use “galvanizing”, but working with it is more difficult - it will not work.

Sometimes they make copper registers - they are used in those networks where the wiring is done. Copper is characterized by high heat transfer (four times more than steel), therefore, their sizes are much more modest (both in length and in diameter of the pipes used). In addition, the wiring pipes themselves (if they are not) give off a sufficient amount of heat. At the same time, the ductility of this metal allows you to bend pipes without special tricks and efforts, and use welding only at the junction of different pieces. But all these pluses are leveled by two big minuses: the first is the high price, the second is the capriciousness of copper to operating conditions. For the price, everything is clear, but for operation a little explanation:

- neutral and clean coolant required, no particulate matter

- the presence of other metals and alloys in the system is not desirable, except for compatible ones - bronze, brass, nickel, chrome, therefore all fittings and fittings will need to be sought from these materials;

- carefully executed grounding is necessary - without it, in the presence of water, the processes of electrochemical corrosion begin;

- softness of the material requires protection - covers are needed, etc.

There are registers of cast iron. But they are too bulky. In addition, they have a very large mass, for them you need to make at least massive racks. In addition, cast iron is distinguished by fragility - one hit, and it can crack. It turns out that this type of registers also needs protective covers, and they reduce heat transfer and increase cost. Moreover, installing them is difficult and hard work. The advantages include high reliability and chemical neutrality: this alloy does not care which heat carrier to work with.

In general, copper and cast iron are not easy. So it turns out that the best choice is steel registers.

Types of Registers

The most common form is registers made of smooth pipes, and most often steel electrowelded ones. Diameters - from 32 mm to 100 mm, sometimes up to 150 mm. They are made of two types - serpentine and register. Moreover, the register can have two types of connections: thread and column. A thread is when the jumpers along which the coolant flows from one pipe to another are installed either on the right or left. It turns out that the coolant sequentially runs around all the pipes, that is, the series connection. When connected as a “column”, all horizontal sections are interconnected at both ends. In this case, the coolant movement is parallel.

Any type of registers can be used for any type of system: with single pipe and with vertical and horizontal type of feed. With any system, greater heat transfer will be when the supply is connected to the upper pipe.

In case of use in systems with natural circulation, it is required to observe a slight bias in the direction of the coolant movement of the order of 0.5 cm per meter of pipe. Such a small slope is explained by a large diameter (small hydraulic resistance).

They make these products not only round, but also from square pipes. They practically do not differ in anything, only it is more difficult to work with them, and the hydraulic resistance is a little more. But the advantages of this design include more compact dimensions with the same volume of coolant.

There are also registers of pipes with fins. In this case, the contact area of \u200b\u200bthe metal with the air increases, and the heat transfer increases. Actually, until now, in some budget new buildings, builders put just such heating devices: the well-known "pipe with fins". With not the best appearance, they warm the rooms well.

If you insert a heater in any heater, you can get a combination heater. It can be separate, not connected to the system, or used as an additional heat source. If the radiator is isolated with heating only from the heater, it is necessary to put an expansion tank at the top point (10% of the total coolant volume). When heated from an expansion tank, it is usually integrated into the structure. If it is not (often in), then in this case it is necessary to install an expansion tank. If the material for the registers is steel, then the tank needs a closed type.

Electric heating can come in handy in the most severe colds when not enough. Also, this option can help out in the offseason, when it makes no sense to download and overclock the system "to the full". It is only necessary to warm up the room a little. With solid fuel boilers this is not possible. But such a backup option will help to warm up in the offseason.

Calculation of registers from smooth pipes

Steel heating registers are easy to do with your own hands. The cost of such a heating system will depend on who will cook them. If you own the welding technique yourself, the option is the most low-budget, if the welder needs to pay, there will not be much difference in cost with inexpensive ones.

At the same time, the registers will occupy larger areas than standard heating devices: because of the insignificant contact surface with air, their efficiency is low. They increase heat transfer by installing a more powerful pump, but there are speed limits due to possible noise in the system. About,

Diameters, as they say - from 32 mm to 100-150 mm. Large pipe sizes lead to an increase in system volume. At the start and acceleration of the system, this is a minus - as long as the coolant heats up, a decent time will pass. When working, a large volume is rather a plus: milder conditions for the boiler. On the other hand, with a large amount of coolant, it is difficult to regulate the temperature.

Heat transfer table for steel pipes of different diameters for different operating conditions of the system (click on the picture to enlarge its size)

The distance between two pipes in the register should not be small: this reduces heat transfer. Therefore, they are placed at a distance of not less than 1.5 radius. The number of rows and the length of the register depend on the required power, as well as on the diameter of the selected pipes. In the general case (for the middle strip of Russia, for rooms with average thermal insulation and a ceiling height of 3 m), we can consider the heat transfer per meter of a steel pipe. These values \u200b\u200bare given in the table. On it you can find the size and number of registers according to the area of \u200b\u200bthe room.

Heat transfer of one meter of steel pipes of different diameters - for calculating the heating register by area

To calculate the heat loss of the room there are averaged data on the heat output per meter of steel pipe. You can use them for standard conditions. If the system operates at other temperatures, adjustments must be made up or down.

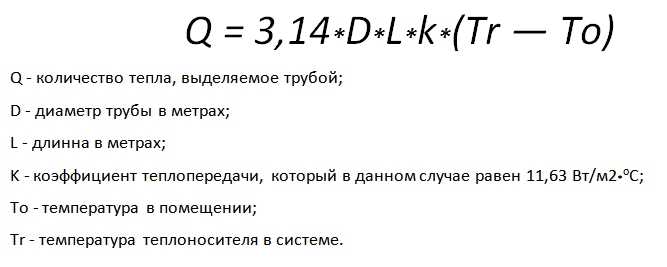

If these tables do not help you, you can do a register calculation using the formula.

Substituting the appropriate values, you will find the heat transfer of one pipe under your conditions. The heat transfer of all subsequent (second or more) will be slightly less. The found value must be multiplied by 0.9. So you will calculate and be able to make a register of smooth pipes with your own hands.

How to install

There are two installation options: to hang on a wall or to put on a rack. The choice depends on the size and weight of the resulting structure, as well as on the type of wall.

Quite often they make a combined installation: they cook racks, which are then attached to the wall. In this way, even very massive registers can be set. Also, this installation option provides a high level of security.

Advantages and disadvantages

The advantages include a simple design and a simple calculation, the availability of materials. All this together allows you to make registers for heating with your own hands.

The next positive point is that most of the heat is transmitted using radiant energy, and it is perceived by a person as more pleasant.

The next plus is a smooth surface that provides easy cleaning.

Excellent quality - compatibility with any systems - with both natural and forced circulation.

Cons also available: low heat dissipation, susceptibility to corrosion, not the most attractive appearance, the need for regular painting ().

Summary

Registered heating in private homes today is used infrequently: there is a large selection of heating devices for different conditions. The price range is also quite wide. But registers of smooth pipes and tubes with fins are often used to heat production, storage and auxiliary rooms, greenhouses, garages, greenhouses, etc. That is, where external attractiveness does not matter.

Steel pipe heating registers are a common type of heater. They represent a welded or prefabricated structure of pipes arranged horizontally. They are connected by jumpers to pass the heat carrier.

The number of radiators used is very large, but the registers have not lost their relevance until this time. These devices are made using different materials, and each of them has its own disadvantages and advantages.

For example, options made of copper are placed on a wiring of copper pipes. Copper is characterized by high heat transfer rates. This is four times higher when compared with steel. Therefore, the size of the length and volume of copper pipe materials is more modest than that of steel options for a similar line.

Also, copper products give off a large amount of heat if they are not. They are also flexible. This makes it possible to bend them without much effort.

An extensive number of advantages in this case eliminates such a significant drawback as the high price and instability of copper to operating conditions. Often put facilities for heating from cast iron.

These devices are bulky. Their heavy weight puts the condition for the installation of massive racks. It should be noted that cast iron is a fragile material.

And therefore, cast-iron heating must be mounted with protective covers. Moreover, the installation itself appears to be a rather laborious process. As you can see, both of the presented options are quite difficult, therefore, the optimal solution in this situation is to use steel heating. For obvious reasons, they have become the most popular species.

Not very high heat dissipation of steel heaters is compensated by their low cost, ease of processing and a large assortment when buying.

It is very rare to find stainless steel registers, but for good power indicators you need a lot of material, and such stainless steel products cost a lot of money.

Heating registers are divided into the following types:

- Smooth pipe designs. In turn, the structures of these species can have a serpentine and register form. Compounds they are of the type of "thread" or "column".

- Products from square pipes. Such options are characterized by higher heat transfer, as they expand the zone of interaction of metal and air. With a not very presentable appearance, such heating devices perfectly warm the room.

Steel heating has a number of advantages:

- When working, you can implement any individual drawing.

- The heat carrier can be not only water, but also heated steam.

- Easy to connect to the system.

- High heat dissipation makes it an excellent option for installation in a large building.

- Low cost.

Video

Cons are also available. These include:

- Small heat transfer rates.

- Fear of corrosion.

- Unpresentable appearance.

- Such products require regular painting.

The algorithm used when creating

- First, pipes of the required volume are prepared and cut into blanks of the required length.

- After that, the internal cleaning of the rolled products is carried out. This reduces the resistance to movement of the heat carrier.

- Plugs are welded on the end parts. Some of them are equipped with holes.

- After that, the pipes, which will be located horizontally, are fastened with vertical pipes, which have a smaller diameter.

- Now it's time to install the cranes. They will be needed in order to release the air accumulated in the pipeline.

- At the final stage, clean all the seams and paint the surface with paint.

Steel registers with ribs

Before installing registers from steel pipes with ribs, it is recommended that the main attention be paid to the volume of the pipe. For a private house, masters advise installations with a volume of 3 or 4 centimeters.

Before installing registers from steel pipes with ribs, it is recommended that the main attention be paid to the volume of the pipe. For a private house, masters advise installations with a volume of 3 or 4 centimeters.

Video

You can take pipes of larger diameter for work, but it should not exceed 8 centimeters. The main reason lies in the heating boiler. A device of the type that is installed in everyday life cannot generate a large amount of thermal energy, sufficient to warm the volumetric areas.

When performing the calculations, it is necessary to take into account the length of one edge of the register and its heat transfer to each square meter. If you give an example, a meter pipe with a 60 mm inside cross section can heat approximately one square meter.

Having counted the required number of registers, rounding is carried out in the direction of increase. But, there are certain conditions under which the obtained indicators are increased by 20, and even by 50 percent. This includes:

- The presence of a large number of openings for windows and doors.

- Small wall thickness.

- Low-quality insulation of the room, or its complete absence.

A simple heating register has less heat transfer than devices with fins. They not only increase heat transfer, but also turn the register into a design - a radiator, which can play an important role in the aesthetic solution of the interior.

Combined appliances

Any device can be supplemented with a heating element, in this way a combined heating device is obtained. It may not be associated with the system, and may be used separately.

Any device can be supplemented with a heating element, in this way a combined heating device is obtained. It may not be associated with the system, and may be used separately.

If this is an isolated register with heating only from the heater, then in its upper part it is necessary to install an expansion tank. Its capacity should not be less than 10% of the capacity of the heating device. For steel registers, closed tanks should be installed.

Video

Such steel structures help out very well in very cold times, when the heating capacity from the boiler becomes few. This option is very practical during the off-season, when it is not advisable to use the network to its full potential. After all, the room at this time needs only a little warming up.

Heat transfer registers

The heat transfer of the registers from steel pipes is the transfer of heat energy between the battery and the medium. Smooth tube heaters are less economical.

The heat transfer of one meter of these structures is approximately 550 W, for a diameter of 3.2 to 21.9 cm. It is recommended that welding installation work be carried out so that there is no mutual heating of the elements.

Under such conditions, the heat transfer coefficient becomes higher. If the register is assembled correctly, then it becomes a reliable and durable heating device made of steel. The heat transfer optimization of a steel pipeline is decided at the design stage of its design. To do this, use such methods.

- Change of infrared radiation in the direction of increase. This can be done with paint.

- Set the ribs, which also increases the necessary design performance.

But, there are cases when these indicators need to be reduced. Such actions are required by sections of the pipeline that pass outside the living quarters. .

The calculations are carried out in this way: Q \u003d K * F * dT. In this formula, Q denotes the coefficient of thermal return, K is the thermal conductivity of steel materials, and F shows the length of the pipe taken for calculations. dT in this formula is the sum of the initial and residual temperature, taking into account the room temperature.

Video

The notation dT is also called the temperature head. You can find it out by adding the temperature at the outlet of the boiler equipment with the numbers at its entrance. The readings are multiplied by 0.5 or divided by two. Room temperature is subtracted from this value.

If the steel heating pipe is in the insulating material, then the resulting number should be multiplied by the efficiency of the insulation material. It shows the percentage of thermal energy of the heating system given during the flow of the heat carrier.

If there is a desire to design the system competently, then it is not worthwhile to select a tube-rolled steel range from steel. Correct calculations in this case not only make it possible to reduce the cost of construction work, but also install the heating system, which will work effectively for a long time.

Installation of steel registers

Registering steel pipes is done in two ways. The first is threaded connectionsand the second by welding. In this matter, solutions are selected based on the total weight of the structure, on its dimensions and characteristics.

Registering steel pipes is done in two ways. The first is threaded connectionsand the second by welding. In this matter, solutions are selected based on the total weight of the structure, on its dimensions and characteristics.

The process itself is similar to the work when connecting radiators. The difference is only in the geometric volumes of the structure. If there is a question of bringing the heating device to gravity networks, then the required slope standards must be observed.

The register should have a slope towards the movement of the heat carrier. For trunk with natural circulation, the described standards are not required.

The rules that are used for the correct connection of steel pipe structures are as follows:

- The minimum standards for distance from windows and walls should be maintained. This distance is 20 cm. These indents are needed for the convenience of repair service.

- When using threaded connections to bring the device, it is recommended to use only gaskets made of paronite, or flax, which is used in plumbing.

- Each steel device must be painted after installation. Otherwise, rust can form on its surface very quickly. At the same time, the thermal conductivity is slightly reduced, but the period of its maintenance-free service is extended.

- All installation work should not be planned for the heating period. After a test check and comparison of the design power of the device, it may be necessary to quickly make changes to the design.

Video

Of the features of the installation, two mounting options can still be distinguished. The first is by hanging the device on the wall, and the second is mounting on racks. The solution in this situation depends on the weight and dimensions of the device and on the type of walls.

The combined version of the fastener design has gained great popularity. To do this, first prepare the racks, and then they are attached to the walls.

This method is suitable even for very heavy heating devices and guarantees a high safety indicator. We must not forget about the air vents, they are supplemented by each heater. The collected air is discharged from the line through an air vent.

Register Dismantling

Both installation and dismantling of registers from steel pipes requires certain skills. You need to have skills in working with welding equipment, a tool for cutting metal and the ability to work with equipment.

Video

It must be clearly understood that the slightest errors will lead to leaks and other serious emergency situations. Own-made devices are best installed in spacious rooms and outbuildings.

If there is no such knowledge, then you should not acquire them during the installation of the heating system. The best way would be to seek help from specialists.

The dismantling of heating devices that have fallen into disrepair, as well as the installation, is best carried out during a period when there is no heating season. When working from the system, it is necessary to drain the water and turn off the heating boiler.

If the heating is connected by a welded method, then the device will have to be cut off with a grinder. If the mount is threaded, then dismantling can be carried out using a lever wrench. In any case, it is impossible to begin such work without specific experience.

Steel pipe heating registers have created serious competition for traditional heating radiators. Such heating structures provide a significant opportunity to save financial resources.

Video

The main advantage in this situation is the ability of the heating device to work even with an aggressive environment. However, in private homes, such steel structures are not used very often, because there is a large selection of other options.

The price range in this case is also quite extensive. Variants of smooth and ribbed pipes are often installed in industrial, auxiliary and storage rooms, garages, greenhouses, etc. That is, in places where external attractiveness does not play a big role.