To organize the heat supply of large rooms, it is impractical to use standard factory batteries and radiators. They have too little heat output and rated power. As their alternative, we can consider heating registers: production from pipes, rules for performing calculations and installation features.

Advantages and disadvantages of heating registers

Home-made steel or aluminum heating registers differ from standard radiators in their sizes. They consist of several pipes whose diameter exceeds 32 mm. To organize the circulation of the coolant, the pipes are interconnected by nozzles.

What determines the popularity of these heat supply devices? Firstly, the possibility of self-manufacturing. You can make bimetal heating registers, steel or aluminum pipes. Plastic models are much less common, as they do not have the proper performance.

Before you connect the heating registers, you should carefully study their "weak" and "strengths".

Benefits of use:

- Long service life. For steel and aluminum models, it can reach 25 years. In this case, the probability of failure will be minimal;

- Greater heat dissipation. This is due to the fact that the power of the heating register exceeds this parameter for classic radiators and batteries. It is associated with a large volume of coolant;

- Simple installation and operation. Since it is possible to correctly set the heating registers by anyone who is at least a little familiar with the rules for organizing heat supply, they can be used in all types of buildings. But most often they can be found in the heating system of large industrial, administrative and commercial premises.

But besides this, it is necessary to take into account possible disadvantages that a heating register from a smooth steel pipe may have:

- Large volume of coolant. This leads to its rapid cooling;

- Minimum air convection. Reduces the efficiency of heat supply;

- Unattractive appearance. Most often this applies to home-made designs.

A correctly calculated heat transfer of a heating register directly depends on its design. Currently, several types of these heat supply devices are used, which differ not only in the material used for manufacturing, but also in appearance.

The mass of a water-filled register can be very high. Therefore, you need to think in advance of a reliable system for fixing it to the wall.

Initially, you should determine the type of design. After all, how to calculate the heating register, if its geometric parameters and the principle of circulation of the coolant are not known? For the manufacture of heating appliances, it is recommended to use standard proven schemes.

The determining parameter is the required rate of circulation of the coolant in the system and the degree of heat transfer of the register. Based on these requirements, you can choose two types of heating devices:

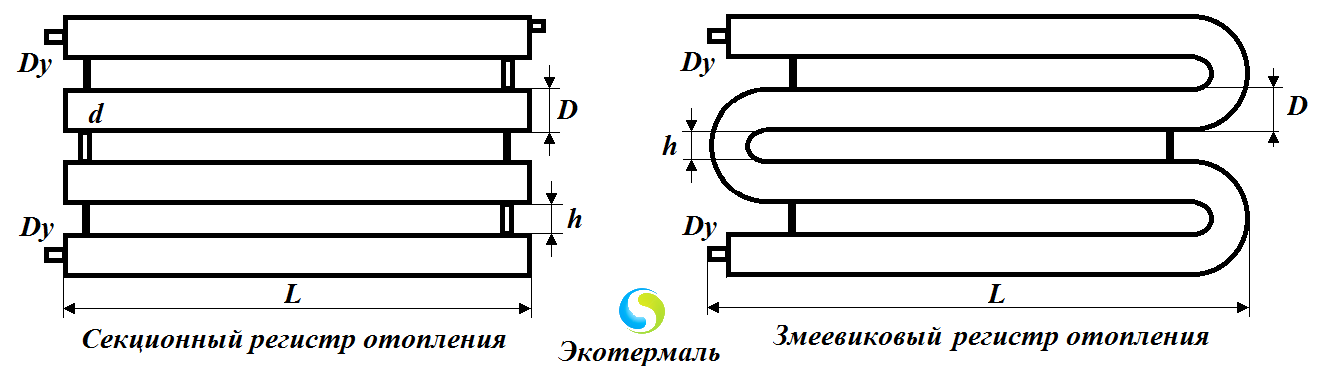

- Sectional. It consists of two or more large diameter pipes connected by nozzles. The cross section of the latter should be equal to the same parameter of the supply line. The selection of a heating register of this type is relevant for systems with forced circulation, since the design creates excessive hydraulic resistance when passing the coolant;

- Serpentine. Consist of one pipe that has bends. Making such home-made heating registers is problematic. To increase the circulation rate, pipes can be connected by nozzles. But this is not mandatory, as in the above models.

Since you can make a heating register with your own hands even at home - they are often made, and not finished models are purchased. But before that, you must perform the correct calculation of the power of the heating register.

For the manufacture of registers, you can use pipes of various sections - round, rectangular or square. Preference is given to the first, since for them the friction of water during movement will be minimal.

Calculation of heating registers

There are several methods for calculating the parameters of heating registers. They are distinguished by accuracy and complexity. But for the organization of heat supply using steel or aluminum heating registers, it is recommended to resort to the services of professionals. An alternative is to use special software.

However, in some cases, it is necessary to correctly calculate the heating register yourself. To do this, you can use the simplified scheme. First you need to know the following parameters:

- The total area of \u200b\u200bthe heated room;

- The heat transfer coefficient of the material of manufacture of the register;

- Diameter of pipes used for manufacturing.

For circular pipes, the calculation of the specific power of the heating register can be done according to the table. These values \u200b\u200bare given for 1 mp pipe register.

However, this method of selecting a heating register has a number of significant drawbacks. Data are given for rooms where the ceiling height does not exceed 3 mp, the thermal mode of the system and the air temperature in the room are not taken into account.

Q \u003d P * D * L * K * Δt

Where Q - specific thermal power, W, P - number π - 3.14, D - pipe diameter, m., L - the length of one section, m, TO - coefficient of thermal conductivity. For metal, this indicator is 11.63 W / m² * C, Δt - temperature difference between the coolant and the air in the room.

Knowing these parameters, you can independently calculate the power of the heating register. Suppose that the length of one section is 2 m and the pipe diameter is 76 mm. Δt is 60 ° C (80-20). In this case, the power of one section of the heating register from a smooth steel pipe will be equal to:

Q \u003d 3.14 * 0.076 * 2 * 11.63 * 60 \u003d 333 W

To calculate each subsequent section of the device, the result obtained must be multiplied by a reduction factor of 0.9.

Using this technique, it is impossible to calculate finned heating registers. Their heat transfer will be higher due to the increased area of \u200b\u200bthe device.

We select the material of manufacture for the registers

The next parameter, which must be taken into account when choosing a register, is the material of its manufacture.

You can rarely see heating registers from profile pipe - most often steel products of circular cross section are used for this.

Currently, several materials are used for the production of registers - metal, aluminum or bimetal pipes.

The difference between it is the calculated heat transfer and the service life:

- Steel heating registers from a profile pipe or round section. They are characterized by ease of manufacture and low cost. The disadvantage is surface rusting. When choosing, special attention should be paid to the quality of the welds;

- Aluminum. They are extremely rare, since equipment is especially necessary for welding aluminum heating registers. But then they have the best thermal conductivity. Virtually no heat loss;

- Bimetallic. They are made from a special type of heating pipe. They have a core made of steel. To increase the heating area, the design has copper or aluminum plate heat exchangers. All bimetal heating registers are characterized by a small pipe diameter of up to 50 mm. Therefore, they are more often used to organize heat supply in residential buildings and small industrial and commercial premises.

Production material directly affects the calculation of the heating register. The main indicator in this case is the coefficient of thermal conductivity. Despite the fact that aluminum models have an optimal value - their high cost and laboriousness of manufacture do not allow the use of registers of this type in heating systems everywhere.

For the manufacture of ribbed heating registers, you can use accessories from steel radiators.

Making registers for DIY heating

One of the advantages of using registers in heating systems is the possibility of their independent manufacture. For this, steel pipes of circular cross section are most often used. Despite the fact that the heat transfer rate of the heating register in this case will not be ideal - the manufacturing process will not require special skills.

For the independent production of this heating element, a pipe with a diameter of 40 to 70 mm is required. A larger value of the cross section will lead to significant heat loss during the circulation of the coolant. You can make a heating register with your own hands according to the following scheme of work:

- Calculation of the optimal parameters of the heating device - the diameter of the pipe, the total length of the section.

- Drawing up a drawing to calculate the optimal amount of material.

- Do-it-yourself heating register manufacturing.

- Checking the design for leaks.

To accomplish this task, you will need a steel pipe designed to form the main registers and a trunk of a smaller diameter. With its help, the registers will be connected to each other and to the heating system. You will also need special end caps for pipes.

At the first stage, it is necessary to cut the pipes to the desired length using a grinder. It is not recommended to use a welding machine for this, since a weld will form from the round pipe at the ends of the heating register. Then, holes are made for connecting the nozzles. The pipes are welded by the welding machine and end caps are mounted. To ensure the safety of the home-made heating register, it is necessary to install an air vent and a drain valve. They are mounted in the upper part of the structure, but on the opposite side relative to the point of connection to the heating.

In some cases, the traditional scheme of a steel or bimetal heating register is modernized. It consists in installing an electric heating heater.

So you can make an autonomous source of heat, which will not depend on the operation of water heating. In the event of an accident or technical work, a home-made heating register will generate heat using a heater. But for this it should be installed during installation stop valvesso that the coolant circulates only inside the heater.

During the selection of the circuit and the manufacture of the heating register, the thickness of the pipe does not matter. The difference in diameters between it and the supply line leads to the complete absence of water hammer in the structure.

Installation of registers in the heating system

Correct installation of heating registers can be done in two ways - on threaded connections or using a welding machine. It all depends on the total weight of the structure, its dimensions and the parameters of the heat supply system.

In general, experts recommend that you follow the same rules as when installing radiators. The difference is only in the size of the structure. If it is necessary to connect the heating register to the gravitational system, the required slope indicator must be observed. The heat supply device should be tilted in the direction of movement of the coolant. For systems with natural circulation, such requirements do not exist.

For the correct installation of the heating registers, the following rules must be followed:

- Compliance with the minimum distances from the wall and window structures. It should be at least 20 cm. This is necessary for technical or repair activities;

- For threaded connection of the heating register, only paranitic linings or sanitary flax are used;

- All heating registers from profile or steel pipes without fail are painted. This is to prevent rust from appearing on their surface.

Despite the fact that the heat transfer coefficient of the heating register will decrease in this case, the period of non-repair service of the structure will increase significantly.

Installation is recommended not during the heating season. After a trial run of the heating system, you can compare the calculated power of the register with the actual and, if necessary, make operational changes to the design.

Rules for the operation of heating registers

To increase the service life, it is necessary to carry out a number of measures to maintain heating registers in working condition. It is recommended to make a schedule of control checks, including a visual inspection and analysis of the temperature regime of the register.

In addition, it is necessary to periodically clean the internal surface of the structure from scale and rust. To do this, it is best to use the hydrodynamic method, since chemical cleaning will require a large amount of special fluid. This can be done without dismantling the structure - it is enough to install nozzles in the manufacture to provide access to the internal cavity of the register.

Each time before the new heating season, structural integrity, reliability of welded and threaded connections. If necessary, gaskets are replaced and repair seams are welded.

Can heating registers be used for heating a private house? This practice exists, but copper pipe products are ordered for this. They are characterized by high cost, but at the same time they have a number of distinctive qualities. Their attractive appearance, which differs significantly from steel structures, is also taken into account.

The video shows an example of manufacturing a register from a steel profile pipe:

Recently, for heating industrial, warehouse and residential premises, special heating registers (RO) are increasingly being used - heating devices that consist of long smooth-walled pipes located around the entire perimeter of the room. As a rule, pipes are placed parallel to the floor and interconnected by jumpers from pipes of smaller diameter, which are also filled with coolant. The simplest example of a heating register is a heated towel rail in a bathroom.

Types and specifications of heating registers

There are several varieties of these devices. Heating registers are classified by material, form of execution and installation method. Let us consider in more detail each group of these devices.

The principle of operation of the device

According to pipe material

- Steel heating registers

The most popular type are appliances made of steel. It is worth saying that steel is a fairly durable material. It is perfectly welded, while it has quite good thermal conductivity.

Sectional RO from steel pipes

- Aluminum devices

Devices from aluminum are somewhat inferior in popularity to steel ones. Nevertheless, they also have some advantages: they weigh a little, look attractive, are more resistant to corrosion, and give off heat well. The only and main drawback of aluminum pipe heaters is their price.

- Cast iron registers

The least popular are the registers of cast-iron pipes. Despite the cheapness, this material is quite fragile and is afraid of mechanical damage. In addition, it does not weld well, which greatly complicates installation.

According to the form of execution

RO can be performed in two main forms:

Sectional - they make such heat exchangers from one or several smooth-walled pipes with a diameter of 25 to 400 mm, which are closed with plugs and connected to each other by nozzles. The coolant enters the upper section through the pipe, and at the opposite end flows to the next section, etc.

S-shaped (coil) - pipes are connected by arcs, i.e. it turns out one continuous pipe. This form allows you to use the entire surface of the device, which leads to an increase in the effective area of \u200b\u200bthe heat exchanger.

Sectional and coil RO

By installation method

Also, heating registers are divided into stationary and portable. Mobile or portable devices of this type are most often used in rooms where it is necessary to temporarily maintain the set temperature before installing the main heating system. For example, during the construction of a new building, or in the garage during repairs. Synthetic oil or antifreeze is used as a heat carrier in such systems, and heat energy is generated by electric heating elements.

Advantages and disadvantages of RO

Sectional register consisting of two sections

Among the advantages of these devices are the following:

- High reliability and durability. Such heaters do not require special attention during operation and at the same time serve for quite some time. Steel pipes will not need repair for at least 25 years. If welding work performed qualitatively, such a device can work even under high pressure, which is ideal for rooms with central heating.

- Low resistance to movement of the coolant due to the large diameter of the pipes.

- Quickly and evenly warm large areas.

- Heating devices can be made according to individual drawings of the developer.

Of the disadvantages it is worth noting:

- Bulky and specific appearance. The large-diameter pipes installed around the entire perimeter of the room “steal” the usable area and are not too pleasing to the eye, although with the right approach, you can originally fit them into the room design concept, making the RO an interesting addition or even a highlight of the interior.

- Difficulty in installation. If the heating system based on radiators and plastic pipelines can be mounted independently, if desired, then the installation of heating registers should be carried out only by specialist welders.

Calculation of the required number of registers

For the correct calculation, you need to take into account the following parameters:

- area of \u200b\u200bthe room;

- heat transfer per square meter of the surface of the material from which the registers are made.

- the diameter of the pipes that will be used for the manufacture of heating appliances.

An approximate calculation of heating registers depending on their diameter is shown in the table below.

The data in the table are indicated when the ceiling height in the room is not more than 3 meters. That is, to heat a garage with an area of \u200b\u200b60 meters, you need 64 meters of pipe with a diameter of 57 mm or 30 meters of pipe with a diameter of 133 mm. After calculations, you need to make drawings. In addition, you should consider all the nuances of the location of the PO in the room.

To summarize. ROs may well compete with other types of heating appliances. It is necessary to select the optimal configuration of equipment individually in each case, taking into account the characteristics of the premises and the wishes of the owner of the house. The manufacture of heating registers and their installation is best left to professionals.

Video: homemade battery (register)

For heating industrial, industrial and warehouse, and more recently - residential and public buildings use heating registers from smooth pipes. The heating register is a device designed to increase the efficient heat transfer between the heat carrier and the external environment.

The registers for heating consist of one or more smooth-walled, connected by pipes with a smaller diameter or made in the form of a coil.

Types of heating registers

Despite the apparent diversity, all models can be divided into two main types: sectional and S-shaped (coil).

Sectional

Sectional devices consist of one or more pipes, closed with plugs. Water flows into the upper pipe through the pipe, then at the other end it flows into the next pipe, etc.

Such a heat exchanger is made of a smooth steel pipe with a diameter of 25 to 400 mm. The most popular diameters are 76, 89, 108 and 159 mm. The inlet and outlet nozzles can be in a threaded or flanged version; welding is also possible.

In addition, the device has a threaded fitting to which an air vent is connected. The maximum working fluid pressure allowed in such devices is 10 kgf / cm² or 1 MPa.

Serpentine

![]()

In the coil pipes are connected by arcs, the diameter of which is equal to sectional, that is, we have one continuous pipe. With this form, the effective heat transfer area increases, since the entire surface of the pipe works.

It is also worth noting that with the S-shaped configuration there are no sections of pipe narrowing, and this significantly reduces the hydraulic resistance of the coolant in the device.

Traditionally, the manufacture of heating registers is made of smooth-walled steel pipe, and carbon steel is most often used. Also there are home-made cast-iron models, models of stainless and low alloy steel.

If you use the register - heating will be effective with a sufficiently compact size of the heat exchanger. That is why this type of heating devices is used in large rooms and production halls.

In addition, it is preferable to use precisely the registers for heating rooms with elevated fire and sanitary standards.

Production of heating registers

If you want to make such a heat exchanger with your own hands, you will need to calculate the heating register. For this, it is most convenient to use the following formula:

Q \u003d Pihdnkhlkhkkh (tg - to) x (1 - ηf)where:

- Pi \u003d 3.14;

- dн - the value of the outer diameter of the pipeline, m;

- l is the length of the section or section, m;

- to - air temperature in the room where the device is planned to be installed;

- tg - temperature of the heat carrier (water) in the pipeline;

- k is the heat transfer coefficient equal to 11.63 W / m² * ° C;

- ηiz - heat transfer coefficient (heat preservation) by insulation, for an insulated device ηiz \u003d 0.6 ÷ 0.8, for a conventional coefficient it is taken equal to zero.

So, for a pipe with a length of, say, 5 meters and a diameter of 159 mm, at a coolant temperature of 80 degrees and a room temperature of 23 degrees, we get the following value:

Q \u003d 3.14x0.159x5x11.63x (80 - 23) x (1 - 0) \u003d 1654.8 W.

This is the power of the heating registers, applicable to a horizontal pipe laid in one row. For several rows, a reduction factor of 0.9 is applied for each additional row.

Advice! Calculation of heating registersit can also be done using online calculators, but you need to be careful: they often give the wrong answer. Therefore, you must first check the calculator with the formula, and only then use it.

Features and specifications

Registers differ in some unique properties:

- Due to the intense heat exchange with the environment, a considerable amount of space can be heated with a fairly modest and compact size of the device itself;

- It does not require high-tech production, it is enough to have electric welding and an angle grinder with a cutting disc;

- It is made of cheap enough material - steel, cast iron or stainless steel;

- Withstands significant pressure (10 kgf / m²) and is able to work not only on water, oil and other liquids, but also on steam;

- It is possible to manufacture according to customer drawings, to independently manufacture and use various configurations, plugs, coating materials and accessories;

- The price of the device, taking into account the effective heat transfer, is much lower than that of other heat exchangers.

Technical characteristics of various instrumentation options can be found in the numerous tables on our website.

Obviously, the heat transfer efficiency will depend on the surface area of \u200b\u200bthe heating. The area, in turn, is directly proportional to the diameter of the pipe and the length of the section.

Attention! Of decisive importance is the number of rows and the distance between them, the sectional or S-shaped configuration of the device, the material, the presence or absence of insulation and the characteristics of the coolant.

Most often, devices with the following characteristics are used:

- The material of which the heat exchanger is made is an electric-welded steel pipe made of carbon steel;

- Types of connections - flanged, threaded with external thread and welded;

- Maximum working pressure - 10 kgf / m²;

- Diameter of sectional and S-shaped pipes - from 32 to 219 mm;

- Recommended minimum distance between pipes - from 50 mm;

- Connecting fittings - jumpers from 32 mm.

Heater registers

You can also meet registers with a heating element - TEN. Such devices are used for installation in rooms where communication is difficult or impossible.

The power of the built-in heating device is from 1.6 to 6 kW. Operating voltage - 220 V, current - alternating single-phase, 50 Hz.

It is also possible to complete with a circulation pump for more efficient heat transfer due to better circulation of the coolant.

When working in stand-alone mode, the device is filled with antifreeze, while the heater maintains a surface temperature of 80 ° C.

When working as part of a central or general home heating system, the heater compensates for the temperature drop in the coolant in the system, or turns off.

Benefits

This type of heat exchanger has the following advantages:

- They have a large heat transfer area with small sizes;

- Convenient to use;

- Easy to clean;

- Fireproof;

- Heaters equipped with heating elements consume little electricity;

- Can be used to dry clothes, clothes or towels;

- Suitable for use in rooms with increased fire safety requirements and increased sanitary standards: in hospitals, workshops, warehouses, retail pavilions, office buildings, hangars, etc.

Conclusion

For those who are interested in this heater, a video has been posted on our website that will help you better understand the features and nuances associated with the manufacture and installation of registers. This instruction is not exhaustive, therefore, we recommend reading the methodological literature on the calculation and design of heating appliances.

Faced with some new concept, a person seeks an answer to a question related to him. One day, one of them may be the question of what are registers? In this case, we are talking about an element of the heating system, which consists of one or a series of smooth-walled pipes. Between themselves they are connected in parallel. The register, in one form or another, is the basis of the majority. It turns out that the heating battery is a register to which metal elements are attached (in one form or another). This allows you to significantly increase the heat transfer area.

What are registers and where can they be used?

This element can be an ideal means for heating, not only in technical and industrial premises, but also in private homes. They are widely used for heating apartments of a small area, as well as for individual rooms equipped with autonomous heating systems. This is due to the fact that such decisions are considered to be effective only when they have a sufficient amount of coolant, the return of which is high in due measure. A large volume of coolant in requires a significant amount of heating energy, as well as a long cooling time, and this ensures the long-term transfer of accumulated heat to the room. Pipes of large diameter, but with a limited length, make such systems more reliable, compact and economical.

Speaking of what registers are, it is worth comparing the efficiency of heating rooms with their help. It is important to note that it is slightly lower than that of traditional radiators. This can be explained by the fact that the heating registers do not have additional metal area. However, the possibilities of their application and methods for increasing heat transfer have a very significant range. It is possible to fix additional metal plates to the smooth-bore pipe during the manufacturing process of heating devices, which will increase heat transfer by several times. If you use general registers by connecting in parallel a lot of thinner tubes, you can not only create effective systembut also give it a decorative touch. They are also sometimes called forms, and they are used for decoration and as heating appliances for destination.

Speaking of what registers are, it is worth comparing the efficiency of heating rooms with their help. It is important to note that it is slightly lower than that of traditional radiators. This can be explained by the fact that the heating registers do not have additional metal area. However, the possibilities of their application and methods for increasing heat transfer have a very significant range. It is possible to fix additional metal plates to the smooth-bore pipe during the manufacturing process of heating devices, which will increase heat transfer by several times. If you use general registers by connecting in parallel a lot of thinner tubes, you can not only create effective systembut also give it a decorative touch. They are also sometimes called forms, and they are used for decoration and as heating appliances for destination.

Understanding what registers are, it can be noted that usually this is 32 millimeters or more. That is why in heating systems, trunk lines made of smooth-bore pipes can already be considered registers.

Understanding what registers are, it can be noted that usually this is 32 millimeters or more. That is why in heating systems, trunk lines made of smooth-bore pipes can already be considered registers.

Application

Since the registers are several pipes placed in parallel and interconnected, they can quite successfully be used in autonomous heating systems, both single-pipe and double-pipe. It is appropriate to use them in houses with any number of storeys. The increased durability allows installing registers in rooms with a central heating system.

Turning to us, be sure that any product will be cheaper with us than in any metal, as we have been specializing in heating registers for many years and work at wholesale prices of a major supplier pipes at the federal level.

Price list for heating registers

The cost of 1 row, 1 m.p. finished product without painting

12.12.2016

In connection with the rise in price of iron, the cost has slightly increased!

| Title | Pipe mm | a type | Price r / m |

| Heating register | 48x3 | serpentine | 390 |

| Heating register | 48x3 | sectional | 370 |

| Heating register | 57x3.5 | serpentine | 470 |

| Heating register | 57x3.5 | sectional | 440 |

| Heating register | 76x3.5 | serpentine | 570 |

| Heating register | 76x3.5 | sectional | 550 |

| Heating register | 89x3.5 | serpentine | 610 |

| Heating register | 89x3.5 | sectional | 570 |

| Heating register | 108x4 | serpentine | 730 |

| Heating register | 108x4 | sectional | 650 |

| Heating register | 114x4 | serpentine | 810 |

| Heating register | 114x4 | sectional | 750 |

| Heating register | 133x4 | serpentine | 950 |

| Heating register | 133x4 | sectional | 850 |

| Heating register | 159x4.5 | serpentine | 1250 |

| Heating register | 159x4.5 | sectional | 1150 |

| Heating register | 219x5 | serpentine | 2150 |

| Heating register | 219x5 | sectional | 1850 |

- Water, Ethylene, Propylene Glycol

Test pressure

16 bar (1.5 MPa)

Operating pressure

from 0.1 to 11 bar (1 MPa)

External diameter

pipe (mm)

Area

heating (m²)

Registers are most often called heating radiators made of metal pipes. The advantage of registers over standard heating radiators is that they can be made according to the size of the room that needs to be heated.

The production company "Svarnoy" offers ready-made registers consisting of several pipes interconnected by hollow jumpers (the coolant runs through the entire structure precisely thanks to these jumpers). Such registers are used in industry and agriculture - for heating industrial premises, in sports - heating gyms, education - they are used for heating basements and gyms of schools. It is possible to use such registers in private homes as well as garages.

Ready-made registers are also available that have a c-shaped connection, which is created from a bent pipe with a diameter similar to the main pipes of the register. Such registers are most often used for heating industrial premises of a large area.

In addition to the ready-made registers, the specialists of the Svarnoy production company are ready to make these heating appliances in the dimensions required by the customer, or for a specific room.

An individual connection is also made to connect the register to the heating network. This connection can be threaded, flanged or prepared for welding.

It is possible to color the registers in color, required by the customer. The inner surface of the pipes also undergoes anti-corrosion treatment.

Additionally, the registers can be equipped with brackets for positioning them along the walls and similar devices for the floor arrangement of registers.

smooth heating registers, manufacturing of heating registers, production of registers

heating, pipe heating register, price heating registers, smooth pipe heating registers,

heating registers from steel pipes, heating registers Moscow, steel heating register