Parallel pipe threads are mainly used for pipe connections, pipe fittings and fittings. This thread spans from 1/16 to 6 "with 28 to 11 threads per 1".

The nominal diameter of the pipe thread is conditionally related to the inner diameter of the pipe. In terms of the ratio of steps and diameters, the pipe thread is a crushed inch thread according to OST 1260. Therefore, pipe thread at one time, before the standardization of small metric threads, was used not only for pipe connections, but also for fasteners, when there was a need to make threads with a relatively in small steps, with large diameters. Pipe threads are the European-wide standard for pipes and pipe connections.

CYLINDRICAL PIPE THREAD DIMENSIONS

(GOST 6357-81)

The standard applies to cylindrical pipe threads used in cylindrical threaded connections, as well as in connections of an internal cylindrical thread with an external tapered thread in accordance with GOST 6211-81.

Tolerances (according to GOST 6357-81) of the average thread diameter are established in two classes of accuracy - A and B. Tolerances of the average thread diameter are total. Tolerances for diameters d 1 and D are not specified.

dimensions, mm

| Thread designation | Number of steps z at a length of 25.4 mm | Step P | Thread diameter | Working height of the profile H 1 | Radius of curvature R | H | H / 6 | |||

| 1st row | 2nd row | outer d \u003d D | average d 2 \u003d D 2 | internal d 1 \u003d D 1 | ||||||

| 1/16" 1/8" | - | 28 | 0,907 | 7,723 | 7,142 | 6,561 | 0,580777 | 0,124557 | 0,871165 | 0,145194 |

| 9,728 | 9,147 | 8,566 | ||||||||

| 1/4" 3/8" | - | 19 | 1,337 | 13,157 | 12,301 | 11,445 | 0,856117 | 0,183603 | 1,284176 | 0,214029 |

| 16,662 | 15,806 | 14,950 | ||||||||

| 1/2" | 5/8" | 14 | 1,814 | 20,955 | 19,793 | 18,631 | 1,161553 | 0,249115 | 1,742331 | 0,290389 |

| 22,911 | 21,749 | 20,587 | ||||||||

| 26,441 | 25,279 | 24,117 | ||||||||

| 30,201 | 29,039 | 27,877 | ||||||||

| 1" | 1 1/8" 1 3/4" | 11 | 2,309 | 33,249 | 31,770 | 30,291 | 1,478515 | 0,317093 | 2,217774 | 0,369629 |

| 37,897 | 36,418 | 34,939 | ||||||||

| 41,910 | 40,431 | 38,952 | ||||||||

| 44,323 | 42,844 | 41,365 | ||||||||

| 47,803 | 46,324 | 44,845 | ||||||||

| 53,746 | 52,267 | 50,788 | ||||||||

| 59,614 | 58,135 | 56,656 | ||||||||

| 2 1/2" 3 1/2" | 2 1/4" 3 3/4" |

65,710 | 64,231 | 62,752 | ||||||

| 75,184 | 73,705 | 72,226 | ||||||||

| 81,534 | 80,055 | 78,576 | ||||||||

| 87,884 | 86,405 | 84,926 | ||||||||

| 93,980 | 92,501 | 91,022 | ||||||||

| 100,330 | 98,851 | 97.372 | ||||||||

| 106,680 | 105,201 | 103,722 | ||||||||

| 4" | 4 1/2" 5 1/2" |

113,030 | 111,551 | 110.072 | ||||||

| 125,730 | 124,251 | 122,772 | ||||||||

| 138,430 | 136,951 | 135,472 | ||||||||

| 151,130 | 149,651 | 148,172 | ||||||||

| 163,830 | 162,351 | 160,872 | ||||||||

| When choosing thread sizes, the 1st row should be preferred to the 2nd. | ||||||||||

SCREWING LENGTHS according to GOST 6357-81

Make-up lengths are classified into two groups: normal N and long L.

dimensions, mm

| Designation thread size | Step P | Make-up length | |

| N | L | ||

| 1/16", 1/8" | 0,907 | cv. 4 to 12 | cv. 12 |

| 1/4", 3/8" | 1,337 | cv. 5 to 16 | cv. sixteen |

| 1/2", 5/8" | 1,814 | cv. 7 to 22 | cv. 22 |

| 1", 1 1/8", 1 1/4", 1 3/8" | 2,309 | cv. 10 to 30 | cv. thirty |

| 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2", 2 3/4", 3" | cv. 12 to 36 | cv. 36 | |

| 3 1/4", 3 1/2", 3 3/4", 4", 4 1/2", 5", 5 1/2", 6" | cv. 13 to 40 | cv. 40 | |

| The numerical values \u200b\u200bof the make-up lengths are established empirically. | |||

The symbol for left-hand threads is supplemented with the letters LH.

Examples of designation for thread accuracy class A:

G 1 1/2-A

left-hand thread accuracy class B:

G 1 1/2 LH-B

Make-up length N is not indicated in the thread designation.

Make-up length L is indicated in millimeters.

G 1 1/2 LH-B-40

Landing is indicated by a fraction: in the numerator of which the designation of the accuracy class of the internal thread is indicated, and in the denominator - the designation of the accuracy class of the external thread.

G 1 1/2-A / A; G 1 1/2 LH-A / B

The connection of an internal pipe cylindrical thread of accuracy class A according to this standard with an external pipe tapered thread according to GOST 6211-81 is designated as follows:

G / R 1 1/2 - A

P.S. At one time, the profile of a cylindrical pipe thread (according to OST 266) extended to diameters up to 18 "with the number of threads per 1" from 28 to 8.

Related documents:

- holes for threading

GOST 3469-91: Microscopes. Lens thread. Dimensions

GOST 4608-81: Metric thread. Interference landings

GOST 5359-77: Eyepiece thread for optical instruments. Profile and dimensions

GOST 6042-83: Round Edison thread. Profiles, sizes and limit sizes

GOST 6111-52 - Conical inch thread with a profile angle of 60 degrees

GOST 6211-81: Conical pipe thread

GOST 6357-81: Cylindrical pipe thread

GOST 8762-75: Round thread with a diameter of 40 mm for gas masks and calibers for it. Basic dimensions

GOST 9000-81 - Metric thread for diameters less than 1 mm. Tolerances

GOST 9484-81: Trapezoidal thread. Profiles

GOST 9562-81: Single-start trapezoidal thread. Tolerances

GOST 9909-81: Thread conical valves and cylinders for gases

GOST 10177-82: Threaded thread. Profile and main dimensions

GOST 11708-82: Thread. Terms and Definitions

GOST 11709-81: Metric thread for plastic parts

GOST 13535-87: Reinforced thrust thread 45 degrees

GOST 13536-68: Round thread for sanitary fittings. Profile, main dimensions, tolerances

GOST 16093-2004: Metric thread. Tolerances. Clearance fits

GOST 16967-81: Metric thread for instrument making. Diameters and steps

GOST 24737-81: Single-start trapezoidal thread. Basic dimensions

GOST 24739-81: Trapezoidal multi-start thread

GOST 25096-82: Threaded thread. Tolerances

GOST 25229-82: Metric conical thread

GOST 28487-90: Tapered tool joint thread for drill string elements. Profile. Dimensions. Tolerances

It would seem that in the pipes is complex? Connect and twist ... But, if you are not a plumber and not an engineer with a specialized education, then questions will surely arise for the answers to which you will have to go where you look. And most likely the first thing they look at is the Internet)

Earlier we talked about diameters metal pipes in this material. Today we will try to clarify the threaded connections of pipes for various purposes. We tried not to clutter up the article with definitions. Basic terminology contains GOST 11708-82 which everyone can familiarize themselves with.

Cylindrical pipe thread. GOST 6357 - 81

Direction: Left

Accuracy class: Class A (increased), Class B (normal)

Why inches?

The inch size came to us from our Western colleagues, since the requirements of the current in the post-Soviet space GOSTa formulated on the basis of the thread BSW (British Standard Whitworth or Whitworth thread). Joseph Whitworth (1803 - 1887), a design engineer and inventor back in 1841, demonstrated the screw profile of the same name for detachable joints and positioned it as a universal, reliable and convenient standard.

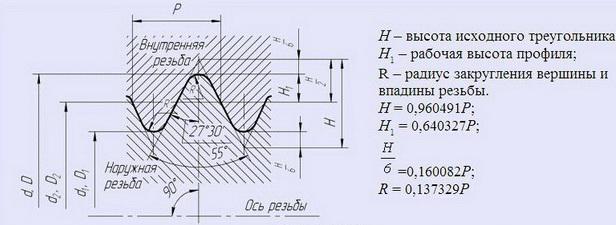

This type of thread is used both in the pipes themselves and in the elements of pipe connections: locknuts, couplings, elbows, tees ( see picture above). In the cross-section of the profile, we see an isosceles triangle with an angle of 55 degrees and curvatures at the tops and valleys of the contour, which are made for high tightness of the connection.

Threads can be tapped up to 6 ”. All larger pipes are fixed by welding for a secure connection and to prevent rupture.

Symbol in the international standard

International: G

Japan: PF

UK: BSPP

Specify the letter G and the bore diameter (inner Ø) of the pipe in inches. The outer diameter of the thread itself is not present in the designation.

Example:

G 1/2 - external cylindrical pipe thread, internal pipe Ø 1/2 "". The outer diameter of the pipe will be 20.995 mm, the number of steps for a length of 25.4 mm will be 14.

The accuracy class (A, B) and the direction of the turns (LH) can also be indicated.

For example:

G 1 ½ - B - cylindrical pipe thread, internal Ø 1 ½ inch, accuracy class B.

G1 ½ LH- B - Cylindrical pipe thread, internal Ø 1 ½ inch, accuracy class B, left-hand.

The make-up length is indicated by the last in mm: G 1 ½ -B-40.

For an internal straight pipe thread, only the pipe Ø for which the hole is intended will be indicated.

Pipe straight thread size table

| Thread size |

Thread pitch, mm |

Threads per inch |

Thread diameters |

|||

How to determine the pitch of an inch thread

Here is a picture for you from the English-speaking Internet, which clearly demonstrates the technique. A pipe thread is characterized not by the size between the tops of the profile, but by the number of turns per inch along the thread axis. An ordinary tape measure or ruler can help. We apply, measure out one inch (25.4 mm) and visually count the number of steps.

In the picture with an example ( see above) threads - literally "threads" in English. In this case, there are 18 of them. one inch.

It's even easier if you have an inch gauge lying around in your toolbox. It is very convenient to take measurements, but it must be remembered that dummy threads can differ in the angle of the top of 55 ° and 60 °.

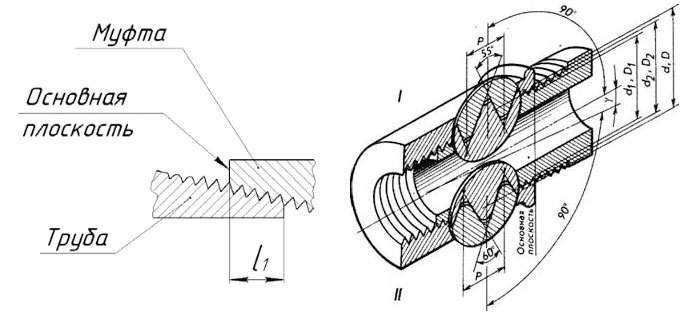

Tapered pipe threads

drawing pipe tapered threads

Tapered pipe thread GOST 6211-81 (1st standard size)

Parameter unit: Inch

Corresponds to the rounded profile of a cylindrical pipe thread with an angle of 55 °. Cm. upper part (I) of the 3D image "drawing of pipe tapered threads".

Symbol

International: R

Japan: PT

UK: BSPT

The letter R and the nominal diameter Dy are indicated. Designation R means external thread, Rc internal, Rp internal cylindrical. By analogy with straight pipe threads, LH is used for left-hand threads.

Examples:

R1 ½ - external pipe tapered thread, nominal diameter Dy \u003d 1 ½ inch.

R1 ½ LH - external pipe tapered thread, nominal diameter Dy \u003d 1 ½ inch, left-hand.

Conical inch thread GOST 6111 - 52 (2nd standard size)

Parameter unit: Inch

Has a profile angle of 60 °. Cm. bottom part (II) of the three-dimensional image "drawing of pipe tapered threads". It is used in pipelines (fuel, water, air) machines and machine tools with relatively low pressure. The use of this type of connection assumes tightness and locking of the thread without additional special means (linen threads, yarn with red lead).

Symbol

Example: K ½ GOST 6111 - 52

It stands for: tapered inch thread with an outer and inner diameter in the main plane approximately equal to the outer and inner Ø of a cylindrical pipe thread G ½

Table of the main parameters of the tapered inch thread

| Thread size designation (d, inches) | Number of threads per 1 "n | Thread pitch S, mm | Thread length, mm | Outside diameter of the thread in the main plane d, mm | |

| Working l1 | From the end of the pipe to the main plane l2 | ||||

| 1/16 | 27 | 0,941 | 6,5 | 4,064 | 7,895 |

| 1/8 | 27 | 0,941 | 7,0 | 4,572 | 10,272 |

| 1/4 | 18 | 1,411 | 9,5 | 5,080 | 13,572 |

| 3/8 | 18 | 1,411 | 10,5 | 6,096 | 17,055 |

| 1/2 | 14 | 1,814 | 13,5 | 8,128 | 21 793 |

| 3/4 | 14 | 1,814 | 14,0 | 8,611 | 26,568 |

| 1 | 11 1/2 | 2,209 | 17,5 | 10,160 | 33,228 |

| 1 1/4 | 11 1/2 | 2,209 | 18,0 | 10,668 | 41,985 |

| 1 1/2 | 11 1/2 | 2,209 | 18,5 | 10,668 | 48,054 |

| 2 | 11 1/2 | 2,209 | 19,0 | 11,074 | 60,092 |

Metric tapered thread. GOST 25229 - 82

Parameter unit: mm

Manufactured on surfaces with a taper of 1:16

Used when connecting pipelines. The angle at the top of the turn is 60 °. The main plane is offset relative to the end ( see pic above).

Symbol

The letters MK are followed by an indication of the diameter in the main plane and the thread pitch in mm: MK 30x2

Metric Tapered Thread Size Chart

| Thread diameter d for a row | Step P | Thread diameter in the main plane | ||||||

| 1 | 2 | d \u003d D | d2 \u003d D2 | d1 \u003d D1 | l | l1 | l2 | |

| 6 | --- | 1 | 6,000 | 5,350 | 4,917 | 8 | 2,5 | 3 |

| 8 | --- | 8,000 | 7,350 | 6,917 | ||||

| 10 | --- | 10,000 | 9,350 | 8,917 | ||||

| 12 | --- | 1,5 | 12,000 | 11,026 | 10,376 | 11 | 3,5 | 4 |

| --- | 14 | 14,000 | 13,026 | 12,376 | ||||

| 16 | --- | 16,000 | 15,026 | 14,376 | ||||

| --- | 18 | 18,000 | 17,026 | 16,376 | ||||

| 20 | --- | 20,000 | 19,026 | 18,376 | ||||

| --- | 22 | 22,000 | 21,026 | 20,376 | ||||

| 24 | --- | 24,000 | 23,026 | 22,376 | ||||

| --- | 27 | 2 | 27,000 | 25,701 | 24,835 | 16 | 5 | 6 |

| 30 | --- | 30,000 | 28,701 | 27,835 | ||||

| --- | 33 | 33,000 | 31,701 | 30,835 | ||||

| 36 | --- | 36,000 | 34,701 | 33,835 | ||||

Characteristic of parallel pipe / inch threads relative to metric

Basic characteristics of "inch" and "pipe" cylindrical threads in relation to "metric" threads for basic dimensions.

|

Nominal thread diameter in dm |

Pipe thread |

|||||

|

outer diameter, in mm |

number of threads per 1 " |

outer diameter, in mm |

number of threads per 1 " |

|||

The quality of the cutting that is performed on the pipeline, its compliance with the diameter of the pipe product - all this has great importance when installing a plumbing or heating system. Cutting an inch thread with a die is not very convenient. It is much easier to use a special machine tool.

Features:

The thread is a screw groove with a constant thread pitch and section. It is performed on products that have the shape of a cone, a cylinder (bolt, screw elements), on parts that are connected to similar products (nuts).

In everyday life, people usually encounter cylindrical threaded joints on pipes. In addition to the thread, the pitch of which is measured in millimeters, inch thread is common in the Russian Federation.

Key parameters metric cut - this is the step (the distance between the grooves or combs, which is measured longitudinally to the axis of the product) and the diameter.

An inch thread is characterized by its diameter, which is measured in inches, by the number of curls per inch. How is the thread size converted to mm from inches? For such a translation, you need to multiply the size of the inch thread by 25.4.

![]()

What else is the difference between an inch and a metric thread? The differences are that the inch thread has:

- pointed combs;

- rounded tops of threaded threads.

Cuts used in everyday life

In domestic conditions, tubular products with the following types of cuts are most often used:

- Fourteen threads per inch (pitch 1.815 mm).

- Eleven threads per inch (2.310 mm pitch).

To establish the type and pitch of an inch thread, an object called a thread gauge is used. In addition, it is possible to use an ordinary ruler, vernier caliper.

A coupling, choke piece can serve as a calibration element. It must be cut with a size that corresponds to the diameter of an inch thread. The part is screwed into a threaded connection. If there are no difficulties, it is firmly seated in the tubular product, which means that the measurement can be completed. If not, repeat the procedure with another calibration piece.

It's even easier with a thread gauge. Its measuring plates resemble a set of nail files. These files must be pressed against the cut made on the product or inside it. If the profile of the plate coincides with the pipe profile, this means that the size of the inch thread is the same as that of the file.

With a caliper it is possible to measure only the outer dimension of the cut. In view of this, calibration parts, thread gauges are considered the best devices for setting the pitch and size of the thread.

In reality, of course, very few people will be able to achieve flawlessly accurate thread dimensions. However, you can count on creating high-quality slices if you follow at least one character in the fractional part of the number.

In reality, of course, very few people will be able to achieve flawlessly accurate thread dimensions. However, you can count on creating high-quality slices if you follow at least one character in the fractional part of the number.

Cutting

If the threading is done by hand, rather than by means of a machine tool, this can cause some difficulties, especially when the outer diameter of the thread exceeds 1 inch.

It is best to use a special device to create a threaded connection. It is called "klupp". Klupp encloses a body with a pair of handles. It houses movable combs that can be adjusted. By means of combs, a gradual deepening of the klupp is performed.

In addition, it is possible to use replaceable combs with full / partial thread profile. They are not very cheap, so not everyone can buy them. You can use a regular die, through which a cut is created.

When the die holder is twisted clockwise, it is screwed onto the thread that is on the sleeve element. The sleeve is fixed to the tubular product using 3 bolt elements. This device has an indisputable plus: there is no need to focus on the pipe product at the beginning of cutting.

Manual creation of slices goes like this:

- the pipe product is fixed in a vice, the tap is installed in the knob, the die is installed in the holder;

- the die is installed on the tubular product, and the tap is installed inside it. Then, scrolling the knob or holder handles, screwing / screwing the tap / die into / onto the tubular product is performed;

- if necessary, the procedure is repeated more than once until a recess is cut in the tubular product, which is equal to the height of the threaded profile.

Of course, the creation of cuts outside and inside does not take place in parallel, but alternately.

Cutting by means of a machine tool is carried out as follows:

- the tubular product is fixed in the lathe chuck. The caliper must have a cutter that matches the thread diameter in inches;

- the device is started, a chamfer is created in the tubular product;

- after chamfering, the tool is fed to the outer / inner part of the pipe, thread feed is started. Before that, the speed of movement of the caliper element is adjusted.

Of course, both the die and the tap can be used on the machine tool, fixing them in the head / tailstock. However, it is worth considering the fact that the parameters of the inch thread created by the cutting tool will be more accurate.

Conclusion

Refer to Inch Thread Size Chart to secure material. It contains GOST data (GOST is a standard adopted in Russia). Remember that not all slices are common in Russia. For example, UNC and UNF are commonly used in the United States of America, Canada.

Do not forget that sometimes it is necessary to convert sizes from one unit to another. To convert millimeters to inches, you need to cut the size, for example, divide UNF (UNF - unified fine thread) by 25.4.

It's okay if you make the mistake of making a threaded connection at home. This is for workers in production to observe GOST. You are free to practice cutting on unnecessary parts.

Allowing to carry out assembly and disassembly work without damaging the integrity of structures, machines and mechanisms. The basis of such a connection is the thread applied to two or more surfaces of the bodies of revolution, which is mainly subdivided depending on the parameters described below. The thread classification is shown in the table below.

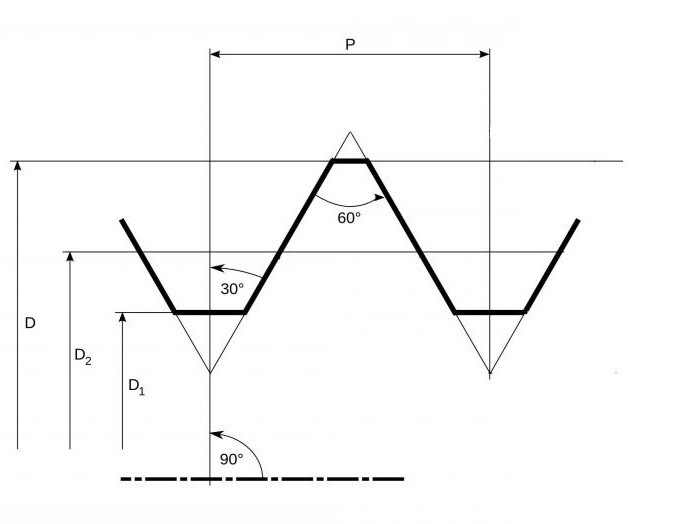

Metric thread

A screw thread on or in a material with a tooth profile in the form of an isosceles triangle is a metric thread, its dimensions are measured in millimeters. This thread is cylindrical in the shape of the application surface, but it can also be conical.

The latter is the most popular to use, especially for the following fasteners:

- bolts;

- anchors;

- screws;

- hardware;

- hairpins;

- nuts and stuff.

A screw thread applied to a tapered base is called a metric tapered thread. It is used in places requiring quick locking of connections, without additional sealing and stopping leakage by simply pulling along the axis. Used when making plugs and pipe connections:

- oil;

- oil;

- gas;

- aquatic;

- air.

It is important to know that tapered and cylindrical threads have the same profile, which allows them to be screwed together. Metric threads are classified by size, direction of rotation, pitch and additional parameters, which are reflected in the marking.

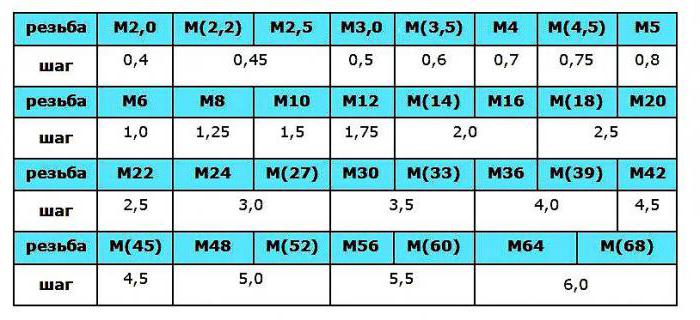

Metric thread sizes

The spread in the diameters of this thread in industry ranges from 0.25 to 600 mm, and with a diameter of more than 68 mm, the thread will only be fine, while up to this value it varies. Coarse threads are used in joints under heavy and shock loading. It is also interesting that for coarse threads the pitch is always fixed in relation to the diameter, in contrast to the fine thread, which can vary, which is separately and additionally indicated when marking.

For example, if "M16" is found in technical documents or drawings at the joints of parts, this means that the letter M is understood as a metric thread. The dimensions of the outer diameter of the threads are 16 mm, and the coarse pitch of the standard thread is 2 mm, according to the information indicated in the table (the thread of the second row is indicated in brackets). So, the main dimensions (GOST 24705-2004).

Fine pitch threads

In the marking, the fine pitch is indicated after the diameter. It looks like this: "M16 × 0.5", where, as we already know, M is a metric thread. The dimensions of the outer diameter are 16 mm, with a step size of 0.5 mm. Interestingly, after a diameter of 2 mm, the difference between the threaded pitch becomes significantly noticeable, leading to separation. Moreover, products of equal diameter have several types of fine thread pitch, as in the one considered in 16 mm:

- 1.5 mm;

- 1.0 mm;

- 0.75 mm;

- 0.5 mm.

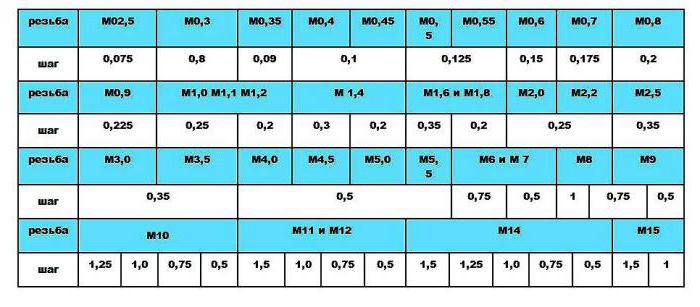

As an example, a part of the table is given that allows you to understand and visually evaluate the range of small threads, without taking into account the large pitch discussed earlier.

Metric thread: basic dimensions (GOST 24705-2004)

Specified parameters

In multi-start threads, the pitch is indicated separately (in brackets), and in its place the number of starts is indicated. This is how this and other optional parameters are indicated when marking:

- (P1) - where P is a pitch of 1 mm, and turns are 3 (example: M42 × 3 (P1));

- LH - left hand thread (example: M40 × 2LH);

- MK - metric tapered thread (example: MK24x1.5);

- EG-M or GM, where G denotes a cylindrical thread on a wire insert or fitting (example: EPL 6-GM5);

- g, h, H - the tolerance range, is the average diameter tolerance in combination with the diameter of the protrusion (example: M12-6g), and with different tolerances of the inner and outer diameters, both tolerances are indicated in the marking (example: M12-6g / 8H).

Thread diameters

There are indicators indicated in the summary tables, which are important to consider in cases where a metric thread is considered - dimensions of diameters:

- external (D and d);

- internal (D 1 and d 1);

- medium (D 2 and d 2);

- inner along the bottom of the depression (d 3).

With widespread use in a threaded connection of a sliding fit, the average diameter has acquired great importance, and in cases of equality of values, the largest d 2 of the bolt and the smallest D 2 of the nut.

Large letters D indicate the diameters of internal threads, and those applied to the external surface of the parts are indicated by small letters - d. The numbers indicate the location. The degree of accuracy of the tolerance fields is classified by letter symbols: E, F, G, H, d, e, f, g, h, and, as in diameters, the size of the letter indicates the location.

Ratio of metric to inch threads

Unlike European and related countries, where the metric system became widespread after the reign of Napoleon, in the countries of the former colonies of Britain and its satellites, all measurements take place in the imperial system. In this system, threads and their connections are measured in inches.

A screw thread with a tooth profile in the form of an isosceles triangle, with an apex angle of 55 degrees. (in the UTS-standard for the USA and Canada - 60 degrees), is called an inch thread, its dimensions are specified in inches, and the pitch is in the number of turns per inch (1 "\u003d 24.5 mm). Such fastening threads are made in the range from 3/16 ", the designation indicates only the outer diameter.

The sizes of inch and metric threads are measured with a caliper, and if in case metric thread this will be enough, then in inch after measurement use a special table. When measuring threads, special templates are used, but there is also a popular way of measuring the step: if, after wrapping the thread with a sheet of paper, scroll the product several times, a trace is printed on the paper, allowing you to measure with a ruler. When using a notebook sheet in a box as paper, there is no need for a ruler - it is enough to count the number of marks in 2 cells (1 cm) and divide by 10.

Hole sizes

The production of threads is due to:

- cold rolling with rollers and heads;

- cutting with cutters, combs or cutters;

- cutting with dies or taps;

- precision casting;

- abrasive or electrical discharge machining.

For cutting external threads, the workpiece is given a cylindrical shape and chamfered, and a hole slightly smaller than the required metric thread (dimensions) is drilled for the internal thread, but larger than its internal diameter. Indeed, when determining the dimensions of the holes for a metric thread, it must be borne in mind that when cutting a notch inside, the material is partially squeezed out, which subsequently participates in the formation of a threaded profile. It is also important to take into account the properties of the material in which the drilling is performed, reducing the size of the drill by 0.1 mm.

Dimensions of metric nuts

A nut is one of the components of fasteners that has an internal thread. They vary in height relative to diameter and strength, in purpose and configuration. The most widely used are turnkey nuts or hex nuts, here is a list of them with an indication of GOSTs:

- GOST 5915-70 - medium size;

- GOST 15523-70 - high;

- GOST 22354-77 - increased strength;

- GOST 5916-70 - low nut with a recess;

- GOST 10605-94 - for a thread diameter of more than 48 mm.

There are many nuts and special purposes, here are examples of some and their GOSTs:

- cap type (hex) - GOST 11860-85;

- for manual screwing (wing nuts) - GOST 3032-74;

- slotted crown - GOST 5919-73;

- rounded with a slot - GOST 11871-88, GOST 10657-80;

- round, with end, radial holes - GOST 6393-73;

- for rigging (eye-nuts) - GOST 22355 (DIN580, DIN 582).

The most important parameter for threaded connections is the match between nuts and threads. The values \u200b\u200bof the more popular threads with a large pitch are indicated in the table below, where S is the wrench size, e — the width of the nut, and m is its height.

Correspondence table of threads and nuts (GOST 5915-70 and GOST 10605-94)

Standards

The main threaded dimensions are subject to GOST 24705-2004, which modifies the standard - ISO 724: 1993 (international classification). This GOST has been the state standard of the Russian Federation since July 1, 2005 and takes into account the interests of the economy of 12 other countries that were previously part of the USSR, which voted for it. It covers the dimensions of GOST 9150 metric threads for general use, as well as the diameters and pitches of GOST 8724.

According to the standards of interchangeability, this GOST refers to the following international and national systems of standards:

- GOST 8724-2002 (ISO 261-1998);

- GOST 9150-2002 (ISO 68-1: 1998);

- GOST 11708-82;

- GOST 16093-2004 (ISO 965-1: 1998 and ISO 965-3: 1998).

This GOST fixes all the main dimensions, possible tolerances, terminology and formulas for calculating diameters:

- D 2 \u003d D - 2 x 3/8 H \u003d D - 0.6495 P;

- d 2 \u003d d - 2 x 3/8 H \u003d d - 0.6495 P;

- D 1 \u003d D - 2 x 5/8 H \u003d D - 1.0825 P;

- d 1 \u003d d - 2 x 5/8 H \u003d d - 1.0825 P;

- d 3 \u003d d - 2 17/24 H \u003d d - 1.2267 P.

It is difficult to imagine modern life without machines and mechanisms, it is even more difficult to imagine technology without detachable connections provided by the thread. Efficiency, relative ease of manufacture and comfortable use ensured threaded connections honorable place in world history.

Parameters such as the quality of the pipe thread, its compliance with the pipe axis play a key role in the installation of plumbing and heating systems... In some cases, do-it-yourself cutting is used. It must be said that this work is difficult, ineffective and takes a lot of time. It is better to cut with a cutter using a lathe.

General thread information

Pipe threads are protrusions and depressions with the same cross-section, evenly spaced on a cylindrical or conical surface (for example, nuts, screws, bolts). They are located along a helical line with the same pitch.

In everyday life, parts with cylindrical threads are usually used. However, there are other types. There are two defining parameters for metric threads: pitch and diameter. Inch threads are so named because their defining characteristics are the diameter, expressed in inches or fractions of an inch. Also an important parameter in this case is the number of turns located per inch length. The size in inches indicates the clearance in the element, while the outer diameter of the part is large.

Pipe thread table according to GOST

Important: One inch equals 2.54 cm. There is also another unit of measurement - pipe inch. It is equal to 33, 249 mm. What is this inch unit? Brought it out like this: to the value in inches was added a value characterizing the thickness of both walls of the pipe.

There are two types of pipes, the classification of which is pipe inch:

- Product with an outer diameter of 33, 249 mm;

- Product with an outer diameter of 21.25 mm.

Inch thread is a set of parameters required to connect pipes, fittings and other parts. Among other things, it differs from metric in such features as:

- Pointed crests-depressions;

- Rounded tops of hills.

Dimensions

In domestic conditions, most often you can find pipes with the following parameters and dimensions, determined by GOST:

- Thread 14 threads 1 inch. In this case, the step is equal to 1.814 mm. The diameter can be ½ or ¾;

- 11 threads per 1 inch. In this case, the pitch is 2.309 mm. The diameter can be 1, 1 ¼, 1 1/2, 2.

Inch threads are only available on pipelines no larger than 6 ". If the pipe parameters are larger, it is mounted in the system by welding works... Its designations according to GOST: G (the value of the passage of elements, indicated in inches), A, B (the degree of accuracy of diameters).

Many parameters are required to select inch pipes. For this purpose, there are a number of tables in which all the important values \u200b\u200bare indicated. There are tables from which you can find out the steps and their ratio with threads per inch. This way you can quickly and easily get acquainted with all the necessary information. You can find all the tables you need on our website. They will help not only amateurs, but also professionals in working with pipes.