In mechanical engineering, three systems of threads are adopted: metric, inch and pipe.

Metric thread (Fig. 145, a) has a triangular profile at an apex of 60 °.

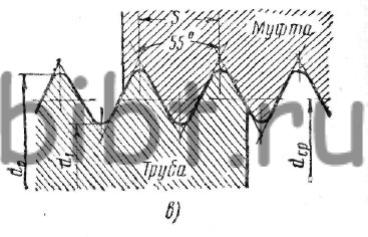

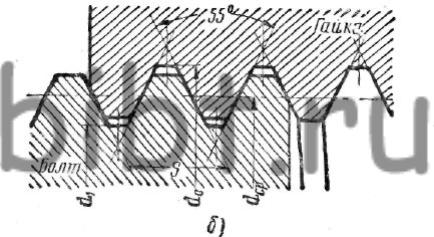

Fig. 145. Thread systems: a - metric, b - inch, c - pipe

There are six types metric threads: main and small -1; 2; 3; 4th and 5th. Small threads differ in pitch with a given diameter, expressed in millimeters. Metric threads are indicated by the letter M and numbers characterizing the dimension of the outer diameter and pitch. For example, M42X4.5 denotes a metric base with an outer diameter of 42 mm and a pitch of 4.5 mm.

Fine thread, in addition, in the designation has a number indicating the thread number, for example 2M20X1.75 - the second metric fine, outer diameter 20 mm, pitch 1.75 mm.

Inch thread (Fig. 145, b) has an angle of 55 ° at the apex. Inch thread is cut in the manufacture of spare parts for machines with inch cuts and should not be cut on new products. Inch threads are characterized by the number of threads per inch (1 ") of length. The outer diameter of an inch thread is measured in inches.

Pipe thread(Fig. 145, c) is measured in the same way as the inch, in inches and is characterized by the number of thread threads per 1 ". The thread profile has an angle of 55 °. For a pipe thread, the diameter of the pipe hole is conventionally taken as the diameter on which its outer surface is cut thread.

The tops of the protrusions at the screw and nut with pipe thread are made with flat or rounded sections.

A flat-cut profile is easier to manufacture and is used for threads of ordinary pipe joints. Pipe thread is designated: 1/4 "PIPE; 1/2" PIPE. etc. (tab. 25).

Table 25 Designation of threads in the drawings

| Type of thread | Legend | Designation Elements | Example of thread designation for bolt and nut |

Metric |

M | Outer diameter of thread (mm) or outer diameter and pitch (mm) | M64 or M64X6 or 64x6 |

Metric small |

1M | 1M 64X4 or 64X4 | |

| 2M | 2M 64X3 or 64X3 | ||

| 3m | 3M 64X2 or 64X2 | ||

| 4M | 4M 64X1.5 or 64X1.5 | ||

| 5M | 5M 64X1 or 64X1 | ||

Trapezoidal |

LADDER | Outer diameter and thread pitch (mm) | LADDER. 22x5 |

| UP | UP 70X10 | ||

Inch with profile angle 55 ° |

Nominal thread diameter in inches | 1" | |

Tubular cylindrical |

PIPE. PR * PIPE. KR ** | Thread designation in inches | 3/4 "PIPE. OL 3/4" PIPE. KR |

Conical tube |

PIPE. CONIC. | 3/4 "PIPE. |

* Profile with plane-cut vertices (straight line). ** Profile rounded.

Threads are right and left; according to the number of visits - one-, two-, three-start and multi-start.

In order to determine the number of thread starts, just look at the end of the screw or nut and calculate how many ends of turns are on it.

As a rule, all fasteners (bolts, screws, screws, etc.) have a single thread.

Threads according to the system of measures are divided into metric and inch. Metric and inch thread applied in threaded connections and helical gears. Threaded connections are detachable connections made using threaded fasteners - bolts, screws, nuts, studs or threads that are directly applied to the parts to be joined.

Metric thread (Fig. 1)

It has the shape of an equilateral triangle in the profile with an apex angle of 60 °. The tops of the protrusions of the mating screw and nut are cut off. Characterized by a metric thread with a screw diameter in millimeters and a thread pitch in millimeters. Metric threads are performed in large and small steps. For the main thread with a large pitch. Small threads are used for adjustment, for screwing thin-walled, as well as dynamically loaded parts. A metric thread with a large pitch is indicated by the letter M and a number expressing the nominal diameter in millimeters, for example M20. For shallow metric thread additionally indicate the step, for example M20x1.5.

Fig. 1 metric thread

Inch thread (Fig. 2)

The inch thread (Fig. 2) has the same appearance in the profile as the metric thread, but it has an angle at the apex of 55 ° (Whitworth thread is the British standard BSW (Ww) and BSF), the angle at the apex is 60 ° (American standard UNC and UNF). The outside diameter of a thread is measured in inches (1 "\u003d 25.4 mm) - dashes (") indicate an inch. This thread is characterized by the number of threads per inch. Inch American threads are made with large (UNC) and small (UNF) steps.

Fig. 2 inch thread

Fastener size chart for American inch UNC large-pitch thread (60 degree profile angle)

| Inch size | Size in mm | Thread Pitch |

| UNC No. 1 | 1.854 | 64 |

| UNC No. 2 | 2.184 | 56 |

| UNC No. 3 | 2.515 | 48 |

| UNC No. 4 | 2.845 | 40 |

| UNC No. 5 | 3.175 | 40 |

| UNC No. 6 | 3.505 | 32 |

| UNC No. 8 | 4.166 | 32 |

| UNC No. 10 | 4.826 | 24 |

| UNC No. 12 | 5.486 | 24 |

| UNC 1/4 | 6.35 | 20 |

| UNC 5/16 | 7.938 | 18 |

| UNC 3/8 | 9.525 | 16 |

| UNC 7/16 | 11.11 | 14 |

| UNC 1/2 | 12.7 | 13 |

| UNC 9/16 | 14.29 | 12 |

| UNC 5/8 | 15.88 | 11 |

| UNC 3/4 | 19.05 | 10 |

| UNC 7/8 | 22.23 | 9 |

| UNC 1 " | 25.4 | 8 |

| UNC 1 1/8 | 28.58 | 7 |

| UNC 1 1/4 | 31.75 | 7 |

| UNC 1 1/2 | 34.93 | 6 |

| UNC 1 3/8 | 38.1 | 6 |

| UNC 1 3/4 | 44.45 | 5 |

| UNC 2 " | 50.8 | 4 1/2 |

Thread

The thread can be internal and external.

- An external thread is cut on bolts, studs, screws, pins and on various other cylindrical parts;

- In fittings, nuts, flanges, plugs, machine parts and metal structures cut the internal thread.

Fig. 3 Thread Elements

The main thread elements are presented in fig. 3 These include the following elements:

- thread pitch - the distance between the peaks or bases of two adjacent turns;

- thread depth - the distance from the top of the thread to its base;

- thread profile angle - the angle enclosed between the sides of the profile in the plane of the axis;

- outside diameter - the largest diameter of the thread of the bolt, measured at the top of the thread perpendicular to the axis of the thread;

- inner diameter - the distance equal to the diameter of the cylinder at which the thread is screwed.

More about inch fasteners:

In this article I want to not only give dry facts about the size of an inch pipe thread with references to standards and GOSTs, but to bring to the reader an interesting fact about the features of the designation of the latter.

So, anyone who has already encountered pipe threads has repeatedly wondered at the discrepancy between the outer diameter of the thread and its designation. For example, a 1/2 inch thread has an outer diameter of 20.95 mm, although logically with metric threads it should be 12.7 mm. The thing is that in inch threads actually indicate the bore of the pipe, and not the outer diameter of the thread. Moreover, adding to the size of the hole in the wall of the pipe, we get an overestimated outer diameter to which we are used to in the designations of metric threads. Conditionally so-called pipe inch is 33.249 mm, i.e. 25.4 + 3.92 + 3.92 (where 25.4 is the passage, 3.92 are the pipe walls). The pipe walls are adopted based on the working pressure for the thread. Depending on the diameter of the pipe, they also increase accordingly, since a pipe with a larger diameter should have thicker walls than a pipe with a smaller dimmer for the same working pressure.

Pipe threads are divided into the following:

Cylindrical pipe thread

This is an inch thread based on a BSW (British Standard Whitworth) thread and corresponds to a BSP (British standard pipe thread) thread, has four pitches of 28.19, 14.11 threads per inch. It is cut into pipes up to size 6 ", pipes over 6" are welded.

Profile angle at apex 55 °, theoretical profile height H \u003d 0.960491P.

Standards:

GOST 6357-81 - The basic norms of interchangeability.

Cylindrical pipe thread. ISO R228, EN 10226, DIN 259, BS 2779, JIS B 0202.

Legend: the letter G, the numerical value of the nominal pipe bore in inches (inch), the accuracy class of the average diameter (A, B), and the letters LH for the left thread. For example, a thread with a nominal diameter of 1 1/4 ", accuracy class A - is designated as G1 1/4-A. Once again, let’s remember that the nominal thread size corresponds to the clearance of the pipe in inches. The outer diameter of the pipe is in a certain proportion with this size and more, respectively, by the thickness of the pipe walls.

Designation of the size of the pipe cylindrical thread (G), steps and nominal values \u200b\u200bof the outer, middle and inner diameters of the thread, mm

| Thread size designation | Step P | Thread diameters | |||

|---|---|---|---|---|---|

| Row 1 | Row 2 | d \u003d D | d 2 \u003d D 2 | d 1 \u003d D 1 | |

| 1/16" | 0,907 | 7,723 | 7,142 | 6,561 | |

| 1/8" | 9,728 | 9,147 | 8,566 | ||

| 1/4" | 1,337 | 13,157 | 12,301 | 11,445 | |

| 3/8" | 16,662 | 15,806 | 14,950 | ||

| 1/2" | 1,814 | 20,955 | 19,793 | 18,631 | |

| 5/8" | 22,911 | 21,749 | 20,587 | ||

| 3/4" | 26,441 | 25,279 | 24,117 | ||

| 7/8" | 30,201 | 29.0Z9 | 27,877 | ||

| 1" | 2,309 | 33,249 | 31,770 | 30,291 | |

| 1⅛" | 37,897 | 36,418 | 34,939 | ||

| 1¼ " | 41,910 | 40,431 | 38,952 | ||

| 1⅜" | 44,323 | 42,844 | 41,365 | ||

| 1½ " | 47,803 | 46,324 | 44,845 | ||

| 1¾ " | 53,746 | 52,267 | 50,788 | ||

| 2" | 59,614 | 58,135 | 56,656 | ||

| 2¼ " | 65,710 | 64,231 | 62,762 | ||

| 2½ " | 75,184 | 73,705 | 72,226 | ||

| 2¾ " | 81,534 | 80,055 | 78,576 | ||

| 3" | 87,884 | 86,405 | 84,926 | ||

| 3¼ " | 93,980 | 92,501 | 91,022 | ||

| 3½ " | 100,330 | 98,851 | 97,372 | ||

| 3¾ " | 106,680 | 105,201 | 103,722 | ||

| 4" | 113,030 | 111,551 | 110,072 | ||

| 4½ " | 125,730 | 124,251 | 122,772 | ||

| 5" | 138,430 | 136,951 | 135,472 | ||

| 5½ " | 151,130 | 148,651 | 148,172 | ||

| 6" | 163,830 | 162,351 | 160,872 | ||

Which are indicated in inches. Many buyers may not pay attention to this, and, therefore, there is a likelihood of acquiring pipes with a size that does not match the required. The reason for this lies in the fact that inch on the surface of the pipe), as the name implies, is measured in inches. In this case, one inch is 25.4 millimeters. This value differs from the accepted millimeter standards, which can greatly complicate the choice of the necessary part.

An inch cylindrical thread provides for the display of pipe dimensions in inches, while it is indicated in fractions of this unit of measurement (due to its small size).

Due to the discrepancy between the millimeter and the inch, in practice there is a significant difference between the dimensions of the thread on the pipe. This is because Western standards say: an inch thread indicates an internal thread. In this case, the differences between a metric inch and the so-called pipe inch should be taken into account.

For example, the pipe indicates that the inch thread has a size of ½. Thus, you get a pipe with an outer diameter of 20.95 mm, instead of the expected 12.7 mm. Consequently, the pipe inch is 33.249 mm and consists of the size of the passage itself and the double wall thickness.

This example shows that the use of this indicator is more acceptable, since such a system best describes the size that an inch thread has.

Now that the notation has become clear, we can proceed to the classification and purpose of this parameter.

The cylindrical inch thread for the purpose and nature of the work carried out is divided into:

- Fixing thread. This type is traditionally classified as metric thread and inch, having a triangular profile. Metric is used in the design of new machines and assemblies, while the second is necessary for the production of various spare parts.

- Special threads include many different sizes that do not meet standards.

Often available with a profile having an angle of 60 °. All values, whether it is a thread pitch or an outer diameter, are indicated in millimeters.

By the size of the step, one main and 5 types of auxiliary thread are distinguished (it is also called shallow). It should be noted that such a thread is considered more durable than coarse (with absolutely equal outer diameters). The undoubted advantage of small threads can also be called a small angle of elevation of the helix and, as a result, increased resistance to torsion.

Threads of this type are used in the most loaded hollow parts, as well as in elements that are subject to strong shocks and shocks. The adjusting nuts also have a similar thread, since it allows for more precise adjustment.

In addition, inch thread can be performed at a rotation angle of 55 °. In this case, the diameter is still set in inches, but the thread pitch is determined by the number of threads per inch. A similar type is used in various parts for mechanical fixation of each other.