You decided to start construction and faced with the problem of laying the foundation for the future building. And indeed, the choice of the type of foundation is very important and directly depends on both the structure you plan to build, and on your financial capabilities. The most relevant of the types of foundation used in private construction in recent years has become. This article will reveal the main points and features of the construction of the budget option.

Why exactly columnar?

This type should be preferred in view of the simple preparatory work, the relatively small material and physical costs, as well as the simplicity and speed of construction. The main material, the so-called “heart” of the structure, will be such an accessible material as pipes. And even if you want to make a columnar foundation of pipes with your own hands, you will not need special expensive special equipment. A special drill (Fig. 1), a concrete mixer and some hand tools, that’s all you need to get started.

A great option for the foundation under a wooden house

- pros

- The cost of materials and physical effort is many times less than other foundations. In particular, the monolithic foundation will cost 2 times more expensive.

- Earthwork is reduced to zero, you do not need to dig a pit and especially level the soil.

- Do-it-yourself high-speed construction of the columnar foundation and the ability to start building the building almost immediately. For comparison, the strip foundation should be spaced at least 28 days, and the columnar foundation only 6-8 days.

- Due to the main building being 20-30cm above the ground, there is no risk of flooding in the event of floods and heavy rains. It also contributes to easier communication (sewage and water supply).

- Minuses

- A small bearing load, which limits their application to the construction of small houses and buildings.

- Relatively short-lived foundation life, about 70-80 years.

- Difficulties in building a basement in buildings built on columnar foundations due to the peculiarities of their construction. Sometimes such an opportunity is completely absent.

- The inability to build on moving soils. And also on terrain with large elevations.

Where to begin?

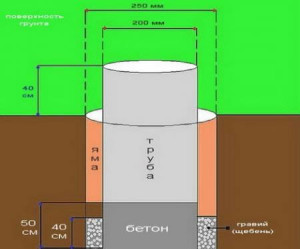

First you need. Next, using a manual or gasoline drill, you need to drill the N-number of wells at a distance of 1.5-2.5 meters from each other (Fig. 2), depending on the calculations and the size of the structure. A prerequisite in this case is the presence of supports under those parts of the building where the greatest load will occur (corners, load-bearing wall, furnace, etc.). The depth at which you will lower the supports should be 25-35 cm below the freezing level, which is on average about 1.4-1.7 meters (Fig. 3). The diameter of the hole will directly depend on the type of pipe that you choose, and will average from 150 to 250mm. And the height of the supports above the ground should not exceed 40-50 cm.

First you need. Next, using a manual or gasoline drill, you need to drill the N-number of wells at a distance of 1.5-2.5 meters from each other (Fig. 2), depending on the calculations and the size of the structure. A prerequisite in this case is the presence of supports under those parts of the building where the greatest load will occur (corners, load-bearing wall, furnace, etc.). The depth at which you will lower the supports should be 25-35 cm below the freezing level, which is on average about 1.4-1.7 meters (Fig. 3). The diameter of the hole will directly depend on the type of pipe that you choose, and will average from 150 to 250mm. And the height of the supports above the ground should not exceed 40-50 cm.

Having decided to build a columnar foundation of pipes with your own hands, you need to decide which pipes you will use as. Your further actions will directly depend on whether you choose plastic, asbestos or metal pipes.

Asbestos pipe column foundation

The use of asbestos pipes as the basis for the foundation is due to their resistance to corrosion (compared to metal pipes) and resistance to low temperatures (compared to plastic). However, it is worth remembering the additional costs of reinforcing bars, which will need to strengthen asbestos pipes.

Construction technology

A pipe with a diameter of 20 cm to a depth of 150 cm and protruding above the soil by 30-40 cm is placed in the prepared well. All columns should be uniform with respect to each other. In fact, the pipe is needed only as a formwork and the main load will go to the metal rods inside it. Next, there are two ways to fill the pipe with concrete and reinforce it with reinforcement.

Ways

In the first cases, two reinforcing rods are driven in at a distance of 6-7 cm from each other. The fittings are driven 20-30 cm deeper than the pipe and protrude just as much beyond its base. Then the pipe is poured with concrete mixture simultaneously from the inside and the outside (Fig. 5). Further, the protruding edges of the reinforcement will serve to form the grillage (grillage is the upper part of the foundation on which the author’s building will be erected later) Fig. 4.

In the first cases, two reinforcing rods are driven in at a distance of 6-7 cm from each other. The fittings are driven 20-30 cm deeper than the pipe and protrude just as much beyond its base. Then the pipe is poured with concrete mixture simultaneously from the inside and the outside (Fig. 5). Further, the protruding edges of the reinforcement will serve to form the grillage (grillage is the upper part of the foundation on which the author’s building will be erected later) Fig. 4.

In the second method, 1/3 of the pipe is poured with concrete mortar and after lifting it 10-15 cm upwards, reinforcing bars that do not protrude beyond its base are lowered into it. In this case, the concrete flows out of the pipe without completely creating broadening, which prevents the piles from being pushed out.  And the raised pipe is immediately set in accordance with the level of the remaining pipes, which is very convenient. Next, the concrete is poured to the edges and a hairpin protruding by 20-30 cm thread is placed in the pipe, and it will serve subsequently as the basis of the grillage. The advantage is the presence of a thread and, accordingly, an easier way to mount the grillage. In this option, when conducting work on loose soil, it is desirable to make a “pillow” (Fig. 6) made of sand and gravel on top of the well with a moisture-resistant material (for example, roofing material or construction cellophane).

And the raised pipe is immediately set in accordance with the level of the remaining pipes, which is very convenient. Next, the concrete is poured to the edges and a hairpin protruding by 20-30 cm thread is placed in the pipe, and it will serve subsequently as the basis of the grillage. The advantage is the presence of a thread and, accordingly, an easier way to mount the grillage. In this option, when conducting work on loose soil, it is desirable to make a “pillow” (Fig. 6) made of sand and gravel on top of the well with a moisture-resistant material (for example, roofing material or construction cellophane).

In both cases, it is desirable to treat the reinforcement with protective agents against moisture and metal wear.

In both cases, it is desirable to treat the reinforcement with protective agents against moisture and metal wear.

Further actions are no different for all types of pipes and come down to the construction of grillages and the actual house itself.

Column foundation made of plastic pipes

This foundation and the method of its construction are almost identical to the previous one and therefore we will only consider the differences, missing the technical part between them.

The advantage of plastic pipes is their general availability and lower price compared to asbestos pipes. They are much lighter and more resistant to harmful substances, but they are afraid of low temperatures and less practical. And compared with metal pipes, this type of pipe has good heat resistance and does not expand during heat.

Column foundation of metal pipes

This type of foundation will require the most expenses from you, but it is the most reliable in comparison with the above and faster in construction. The most difficult moment when installing the foundation of metal pipes is the accuracy of their level relative to each other. In the case of asbestos and plastic for alignment, it is quite simple to file the pipes. It is also worth paying special attention to the treatment of pipes with anti-corrosion agents, otherwise your design will not stand idle for more than 20 years.

Pile screw foundation video:

There are also two technologies for pouring pit concrete mixture.

So, what is next?

After completing the foundation and hardening of concrete (about 5-7 days), you will need to decide what type of grillage you choose for your future creation. The most economical option would be a wooden flooring using screw connections, but this is true only for small buildings (bath, household. Buildings). For capital buildings, you can use a metal frame, or concrete casting under load-bearing walls.How to strengthen the column foundation?

Unfortunately, with a do-it-yourself columnar foundation of pipes, if the load is incorrectly calculated or the construction is incorrect, critical changes can occur that entail a skew of the structure, its landing in some places, or cracks in the bearing walls.

What to do?

If the problem spot was identified immediately, then do not panic. If as a basis you have metal pipes protruding over the ground, then in the simplest way you will weld several additional profiles to them and thus connect them together.

For plastic and asbestos pipes, you will have to resort to digging trenches, in the area of \u200b\u200bsubsidence, and pouring a monolithic foundation.

Another, more costly way, is to drill holes in the part of the asbestos and plastic pipes that protrude above the ground, into which screws or anchors are drilled and reinforced rods are welded to them, thereby ensuring a rigid connection between all the supports.

In the most extreme case, you can use the special equipment to lift the building from the sagging side, and tear out a trench, to build a strip or monolithic foundation.

The question price or how much does the columnar foundation cost?

I think you have already chosen that columned foundation from pipes with your own hands whose construction is more preferable and convenient for you.

First, we summarize the total cost for all types of pipes.

Cement

So, the foundation of your foundation is cement. For small buildings, in order to save, m-400 cement is suitable, for capital and large structures m-500. The average price on the Russian market fluctuates for the m-400 in the region of 160-180 rubles. for 50 kg, for m-500 from 230 to 290, depending on the manufacturer. Sand will cost us 350-450 rubles. per 1 ton, plus crushed stone will cost around 480-520 rubles / t.

The total volume of the required concrete mix must be calculated individually, depending on the depth and diameter of the wells, as well as on the type of pipe and the use of reinforcement.

Pipes

The most economical plastic pipes, depending on the diameter, will cost you from 50 to 250 rubles. per meter. It is worth considering that transportation due to their ease can be done manually, without ordering a truck.

Asbestos pipes will cost your wallet an average of 450-750 rubles. for 1 pc. It is worth considering that it is more profitable to buy longer pipes and then simply saw them into two halves.

For both types of pipes listed above, the price of fittings should be added to the cost. And based on the diameter, as well as prices for 1 meter of the product, or 1 kg, the average cost will range from 250-350 rubles per 1 meter / kg.

Metal pipes will pour you a pretty penny, and depending on the diameter and wall thickness of the pipe, they will cost 650-800 rubles per meter. And although for metal pipes it is not necessary to separately purchase fittings, they will require additional costs for anticorrosive agents. But there are two small nuances, firstly, you can buy pipes that are already resistant to a hostile environment, and secondly, you can save a little by purchasing pipes that were already in use.

Video:

Earthwork

It all depends on you. If time permits, it will not be difficult to do all the preparation and drilling of wells alone. The only item of expenditure is the cost of acquiring a drill (manual will cost 1200-1500 rubles), it is better to buy a special drilling machine, it will greatly speed up the process.

Another point, in view of the design features, is the need to sprinkle soil under the building with slag or rubble. To prevent the growth of various plants and grass.

Summarize!

With a reasonable approach and a little dexterity, using this method you can erect a columnar foundation from pipes with your own hands in the shortest possible time and for a moderate fee. So the dream of your home, small cottage or your own bathhouse, has become one step closer to you.

A barn is an indispensable and important attribute of a personal plot. Thanks to an extensive selection of materials and tools, it is possible to independently create a building without the help of specialists. And all work begins with the foundation.

What you need to pay attention to before starting construction

Foundations for sheds should be selected taking into account the properties and type of soil available. Thanks to the competent, it is possible to select the best option for the foundation.

Types of soil:

- sandy loam;

- loam;

- gravel

- clayey;

- rocky.

Despite the lightness and simplicity of construction, for its construction is considered the most suitable soil of rock type in the form of a dense array without voids and cracks. It is distinguished by the absence of quicksand, freezing in the cold season, subsidence, the ability to give the foundation and the entire structure sufficient stability.

New technologies

Thanks to the development of the laying field of such bases, it becomes possible to carry out high-quality construction on gravel, as well as on sandy loam and loam. Thus, subsidence of the soil, its substantial compression, as well as the presence of quicksand frosty heaving becomes less fundamental.

The swelling of the soil can occur both on the sides of the structure, and under it. Foundations for sheds can be protected from this in the following ways:

- removal of heaving soil at the construction site and its replacement with crushed stone and coarse sand;

- creation of a monolithic foundation;

- waterproofing and base insulation from all sides;

- foundation deepening below the freezing level.

Grout

High-quality ensure the reliability and strength of buildings. Particular attention should be paid to the components of the solution. Standard Portland cement is distinguished by sufficient characteristics, but it must have a fresh production date. It is advisable to purchase crushed stone of a small fraction, due to this, the consumption of materials is reduced, the solution becomes denser when laying and more monolithic when solidifying. It is important that there are no impurities and debris in all components, including water. To obtain a solution, cement, crushed stone and sand are mixed in the prescribed ratio, then water is added portionwise to form a uniform, dense mass.

What to build a building on

The type of base is selected depending on financial capabilities, resistance to negative effects (freezing, groundwater) and available on the ground.

Strip foundations for sheds are more versatile and durable. Their construction begins by digging a trench. Before this, the site is marked, and around the perimeter of the future building, stakes are installed with twine stretched between them.

The base will gain additional strength and solidity if it is poured over one day and carefully tamped. It is worth remembering that it takes several days to set concrete, and during the heat, to periodically crack it, it is periodically doused with water.

Column foundation under the barn

This is a more budgetary and easy version of the arrangement, for the implementation of which it will not require the involvement of special equipment and an appeal to specialists. Since the base rests on several pillars dug in the ground, you do not need to dig a full trench. Caution should be exercised when choosing this option for moving soil, but it is optimally suited for uneven areas.

Column foundation technology

Clayy soil is preferably sprinkled with gravel. The depth of digging of pillars for the support is calculated taking into account the level of freezing, it is necessary to add another 15 cm to this value. Supports made of brick or concrete are installed at the joints of the walls and at the corners of the base. The bottom of each depression is covered with sand and gravel, followed by tamping. To increase the strength in the center is a steel rod.

To prevent subsidence of the structure, a reinforced concrete base is laid at the bottom. The laying of the pillars will take up the remaining space in the recesses. It is possible to use pipes filled with concrete, blocks, bricks. When using the latter, coating with a waterproofing compound is necessary. The column foundation for the barn requires protection against moisture also at the joints of the walls and the base, especially if it is planned to build from wood.

For light wooden buildings can be made of similar material. For waterproofing, impregnation with special mastics or firing is used. Due to this, the barn is environmentally friendly and budget.

Foundation for a block shed

The foam block is a light and durable material with an acceptable cost. Installing it is easy enough even for those who have never done such work. They are used both for the base and for walls, allowing to reduce the total load on the soil. Construction begins by digging a trench or foundation pit if basement construction is required.

The depth calculation specified above is used, the width in this case is made up of the block thickness and an additional 20 cm. A pillow of sand and gravel is poured onto the bottom of the pit (trench), then a formwork with a reinforcing cage is installed. Concrete is poured from above, its layer should be about 20 cm. Installation of foam blocks is possible only after complete solidification.

The foundation for a shed of foam blocks is characterized by ease of installation, affordable cost, resistance to the influence of acidic soil and freezing, a long period of operation and low time costs for its arrangement.

The installation of foam blocks from corner points begins. External joints are filled with moisture protection agents. The base is wrapped on the outside with the selected waterproofing material, then the trench is buried.

at the base of buildings

Foundations are formed for sheds of the type with their installation in drilled wells and pouring with a mixture of concrete. Used to increase reliability and durability. But, like any other design, it has its own advantages and disadvantages.

Among the shortcomings, it is worth noting the fragility of use. It has a maximum operating period of about 70 years, given the fact that the reinforced concrete foundation can stand for several hundred years, the foundations of stone and brick also have a long service life.

The columnar construction of pipes cannot be used on soft soils, wetlands and in areas with large changes in relief.

Despite this, this type of foundation has many advantages:

- It takes about a week to gain strength, after which you can begin further work.

- There is no need to purchase lumber to create formwork.

- Low cost. Asbestos-cement type pipes are much cheaper than concrete blocks or reinforced concrete piles.

- There is no need to dig a trench, level the bottom and fill up the sand-gravel mixture, as some types of bases require.

- Installation does not require lifting equipment and specialist assistance.

When choosing a foundation for a future building, it is necessary to take into account the advantages of the chosen design: stability, resistance to moving soils, strength. However, such qualities as the cost of the material and the possibility of independent construction play a large role. To save the family budget, you can build a tubular foundation with your own hands, but even a simple and affordable option requires theoretical training and groundwork skills.

Methods for strengthening asbestos, metal or plastic pipes in the ground have some differences

The advantages of a pipe foundation

The tubular foundation is a kind of pile construction, the construction of which does not use concrete blocks, poles or beams, and not wooden supports, but various types of pipes - metal, plastic or asbestos. Novice builders prefer the point option because of the ease of translating the project into reality, while more experienced ones like a modest estimate and quickly achieve results.

One of the options for installing in the soil pipes with a diameter of 200 mm

Non-professionals who have already had to deal with the installation of a pipe foundation, highlight the following advantages:

- land work is minimized - there is no need for a large foundation pit or perfectly leveled site;

- laying takes a short period of time, after which you can start building a house (a week is enough for aging, while the strip foundation "ripens" 3-4 weeks);

- laying communications does not cause difficulties;

- the building is protected from possible flooding, since the count of supports is elevated above the ground.

The height above ground level depends on the type and size of the building

If we roughly calculate the amount of material and the cost of construction work (services of a brigade of workers), we will see that the tape construction will cost twice as much. Metal or plastic pipes for the pile foundation, a land drill, a concrete mixer - these are perhaps the most expensive points of the project. A hand tool, necessary for the construction of formwork, is in every home.

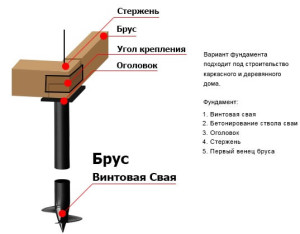

The scheme of the foundation device on screw piles

Do-it-yourself tubular foundation construction

Before starting excavation, you should reflect the plan of the future structure on paper, make detailed calculations, study the site and make markings. The main factors directly related to the foundation are the supports themselves (their number, type, intervals between them), the depth of the pits, soil characteristics, ground load, the presence or absence of groundwater, and the height of the structure above ground level.

An approximate scheme for creating a buried tubular foundation

Plastic pipe construction

When choosing plastic pipes for a column foundation, we focus on more durable products designed for external sewage. They are easily recognizable by the brick-orange color, while the products for interior use are gray. Manufacturers give a guarantee of 45-50 years, but if you reinforce the formwork with reinforcement or frame, the supports will last 20 years longer.

Pipes for external sewage differ in color and technical characteristics.

PVC pipes for external sewage have a set of characteristics that are valuable for earthwork and building construction under heavy load:

- easily tolerate low temperatures, which allows them to be used in mid-latitudes and in the north;

- resistant to external aggressive effects (chemical and mechanical);

- despite the strength of the material, they are light weight;

- thanks to a smooth surface, soil motions are better tolerated.

Depending on the area and height of the building, we determine the optimal parameters of the pipes: length (from 1000 mm to 6000 mm) and diameter (from 110 mm to 630 mm).

Work order:

- We draw up a foundation project from pvc pipes, taking into account the nuances of building with our own hands, not forgetting about the number of supports, the intervals between them, and the depth of the pits.

- We prepare the main material - plastic blanks for formwork. In order for the supports to acquire additional strength and stability, in the lower part it is necessary to make a broadening, the so-called “heel” - we take a black dense garbage bag and fix it with tape.

- In advance we weld the frame from the reinforcement for each support, we prepare the studs for fastening the lower harness from the beam (the stud will “peek out” from the concrete pouring).

- We drill holes exactly according to the marking so that the lower part of the supports is below the freezing level.

- We insert the PVC blanks into the wells, concreting the broadening. We observe the general level of height, for this we use a stretched building cord. A second option is also possible - cutting blanks at one level after installation.

- We reinforce the formwork with pre-prepared reinforcement frames.

- The final stage - we fill each pillar with concrete. In the upper part we fix the hairpin.

To increase the service life and protect the supports from destruction, the upper part, towering above the ground, is treated with bituminous mastic or covered with roofing material.

Metal supports

The main advantage of the foundation of metal pipes is its durability. Unlike plastic and asbestos analogues, steel piles will stand idle for more than one hundred years, but with the only condition - if you carry out the correct anti-corrosion treatment of the supports along the entire length. Another drawback is the high price of products, but it justifies itself if you are building not a utility room for tools, but a country house for temporary or permanent residence.

Construction of a frame house on a tubular foundation

Metal is not as easy to process as asbestos or polyvinyl chloride, so when driving piles you need to monitor the level. With inaccurate compliance with the specified height, it will be necessary to file steel supports, and this will take a lot of time and effort.

There are two ways to install metal supports:

- Simultaneous concrete pouring of pipes and pits (a section located inside the perimeter of the foundation). To comply with the horizontal and increase strength, use a metal frame that connects all the supports - grillage. For welding grillage, a galvanized steel profile is suitable.

- The use of double pipes - first they drive a base of a larger diameter, load bearing supports are inserted into it, then they are poured with concrete. This method protects against metal deformation, which is possible in the hot season.

If the foundation is being prepared for the construction of a residential building and the arrangement of communications is required, it must be remembered that the sealing of the glands during the passage of pipes through the foundations, the cellars of the cellars is governed by the standards of state estimated norms.

Combined asbestos cement foundation

Asbestos cement, along with metal supports, is used to arrange a columnar foundation from pipes. It is proved that combined structures are much stronger than point supports, therefore, concrete tape is used as additional protection. Formwork is constructed in the usual way from sheet metal, wooden boards or sheets of plywood.

Asbestos-cement or metal pipes are connected by a grillage from a corner or profile

The main thing when pouring concrete is waterproofing the inside and the absence of cracks and cracks. It is worth abandoning the strip foundation if the construction is carried out on moving soils, since additional concrete pouring can cause the destruction of the entire structure as a whole.

Thematic video

Video: Foundation on screw piles

With the simplicity and ease of erection, structures of a tubular type are not always used. For example, they are relevant when it is planned to build a small wooden structure in area, and for a stone cottage with an increased bearing load, a strip foundation is preferable.

Video: Pile-screw foundations

Due to the raised open structure and the lack of a pit, there is a difficulty in building a cellar or basement. In areas with variable heights or with moving soil, another type of structure should also be chosen.

The foundation of any structure is the foundation, the structure on which the building rests, transfers its weight to the underlying soil and therefore is one of its most important elements. The most popular type, in terms of its simplicity and cost-effectiveness, is columnar.

Depending on the materials used, columnar foundations can be as follows: brick; concrete - monolithic or from finished blocks; wooden; from a metal profile; from pipes: asbestos-cement, plastic, metal. From the whole variety of columnar structures, one can distinguish the foundation from steel pipes, which is often used in the construction of single-story buildings and few critical buildings - garages, pantries, sheds, large arbors, grill houses.

It is a field of pillars located in the corners of the building, at the intersection of the outer walls and supporting partitions. The recommended pipe pitch is 1.5-3.0 m, depending on the weight of the building. Such structures are successfully used in areas with a slope and during construction on soft soils and can be built with your own hands.

The main advantages of the pipe foundation are high load-bearing capacity, the absence of deformations when observing the device technology, large earthworks are not required, a short construction period and low cost, because it does not require the use of complex construction equipment for digging a foundation pit and planning the territory and its can do it yourself. In addition, such a foundation will require a small amount of reinforcement and concrete.

Subject to technology, the foundation quickly gains the necessary strength and has a long service life. The advantages of the foundation of pipes include the possibility of its installation in flooded and moist areas. In addition, the supply of communications to such buildings is quite simple.

The disadvantages of such a foundation include:

- relatively low bearing capacity and, as a result, limited use;

- the need for floor insulation during the operation of the building in the cold season;

- the impossibility of building a basement; inability to use in areas with a large slope.

Piles of 2-3 pipes of smaller diameter are possible, which are installed at a distance of about 5 cm from each other.

Consider the sequence of the device foundation from the pipes with your own hands.

Preparatory work

For the proper construction of the foundation, it is necessary to take into account the following parameters: the depth of freezing of the soil at the construction site, the presence and depth of groundwater, soil characteristics, the total weight of the building.

Pipes with a diameter of 250 mm

Pipes with a diameter of 250 mm Then you should prepare tools and materials:

- motorcycle or hand drill;

- concrete mixer;

- welding machine;

- grinder, screwdriver;

- hammer;

- nails

- level;

- cement, brand not less than 400;

- sand;

- crushed stone or gravel;

- rebar with a diameter of 10 or 12 mm;

- boards for wooden grillage or formwork for concrete grillage;

- pipes D \u003d 250-300 mm;

- bitumen or bitumen mastic.

The site is marked, pegs are driven into the places of future wells, the recommended step is 1.5-3 m. Pipes are prepared: the length of the pipes should be half a meter longer than the depth of the well, the surface of the pipe and the bottom end are carefully coated with bitumen mastic or heated bitumen, which is recommended add 10% of working off to give more elasticity.

DIY foundation

Using a manual or gasoline drill, wells are drilled to install pipes. The depth of the well, about half a meter below the depth of freezing of soil in a particular area (for the Moscow region take 1.8 m). Sand or gravel is poured into the well to create a drainage layer of 150-200 mm. Then the prepared pipes are immersed, with the help of a level and a long board, the horizontalness of the pile field is checked, if necessary, the pipes are cut with a grinder.

Using a manual or gasoline drill, wells are drilled to install pipes. The depth of the well, about half a meter below the depth of freezing of soil in a particular area (for the Moscow region take 1.8 m). Sand or gravel is poured into the well to create a drainage layer of 150-200 mm. Then the prepared pipes are immersed, with the help of a level and a long board, the horizontalness of the pile field is checked, if necessary, the pipes are cut with a grinder.

The internal volume of the pipes and in the presence of a gap between the walls of the pipe and the well, this space is filled with concrete with layer-by-layer baying. When constructing a building with a height of more than one floor, 3-4 rods of reinforcement should be placed in the pipe.

In 5-7 days after filling the pipes with concrete and the initial set of strength, we proceed to the next step of making the foundation of the building with our own hands - installation of the grillage. The grillage can be made of wooden bars, metal (channel or profile pipe) or concrete. Concrete - the most time-consuming, but more affordable for the device with your own hands. To make it, you need to install a wooden formwork 200-300 mm above the ground, 0.5 m wide, 0.3-0.5 m high. Watch a video on how to fill the foundation with pipes yourself.

Fittings are laid, it is advisable to weld individual rods to the pipes. The formwork is lined with a cellophane film inside to prevent leakage of cement milk. Formwork in layers, filled with concrete with bayonet. After 5-7 days, the formwork can be removed. The foundation is ready for the construction of a house or any outbuilding.

The foundation of steel pipes is the most common design and available for the device with your own hands, has a high bearing capacity and low cost. Also, its advantage is that it is suitable for use in flooded areas.

Various types of pile foundations are used quite often used in both civil and industrial construction. One of the varieties of such solutions is the columnar foundation of pipes.

Of course, it is not always applicable, but convenient enough in the device. What factors influence the possibility of its creation, how to correctly calculate its parameters and then correctly arrange it “in place” is described in the following article.

The advantages of pipe foundations

Universal foundations that will work equally well in any soil - any engineer will say that. Column foundations also have their own sphere of application, within the framework of which they show themselves better than other types - such as strip or monolithic ones.

But the pipe foundation has an additional number of advantages over its “columnar” class counterparts.

Advantages of columnar bases

- Low (2 or more times) in comparison with prefabricated and monolithic foundations

- Low excavation

- Simplicity and speed of the device

- Sufficient durability for most low-rise buildings

- Removing the building's load-bearing structures above the ground level, which means possible washing out by flood waters

- The best load distribution from the structure to the ground

- Ability to device on heaving soils

Additional advantages of pipe foundations

- Standard equipment is available on the market and allows you to provide any depth and diameter of the pillar.

- Source materials are very cheap

- Transportation costs, especially when using plastic pipes, can be reduced to an absolute minimum.

- Drilling holes for laying pipes requires a minimum of earthwork. Using a drilling rig will cost less than the work of an excavator, and with a small depth of laying and low weight of the building, you can do completely with an electric, gasoline or manual garden drill

- The pipe plays the role of fixed formwork and provides a clear geometry of all poles in diameter and depth

- When using poles do not need additional reinforcement

- No masonry needed

Conditions restricting the use of columnar foundations

- The device of this type of base is not recommended in horizontally moving soils due to poor rollover stability.

- The foundation should not be laid on pipes in weakly-bearing, water-saturated and subsiding soils, as well as for buildings with powerful stone walls

- Such grounds are not applicable for most areas with significant differences in elevation under the building (from 2 m and above)

- The construction of a basement under a house with such a foundation requires significant costs and effort.

The order of the device of the pipe foundation

Circuit diagram

Structurally, the foundation pillar itself consists of:

- Pipe housings

- Broad "shoe" (not in all designs)

- Embedded reinforcement

- Waterproofing layer

- Concrete mixture filling the pipe

The shoe is designed to increase the resistance of the column to ejection from the ground as a result of heaving.

Important information!

Under the waterproofing, a layer of bitumen or other, which has similar properties of mastic, is often laid.

It contributes to the sliding of the soil on the surface of the column during expansion, as a result, the soil rises, and the foundation structure remains motionless.

Foundation pillars are laid without fail at the corners of the house and the junction of all walls - both external and internal, in the walls, depending on the calculated load, the step is 1.5 - 2.5 m.

In most cases, the columnar foundation of the pipes is equipped with a grillage - a continuous strapping that connects all the supports, and transfers the weight of the walls and other structures to them.

In this case, most often grillages are made of:

- Reinforced concrete lintels, including - and in several rows

- Reinforced concrete beams

- Monolithic reinforced concrete

- Metal beams

- Brusa

In addition to creating rollover stability, the grillage provides an even distribution of the building weight over all supports, and the joint work of the posts in the event of soil movements. Also, the height of the grillage above the ground allows vertical movement of the soil in case of heaving without threatening the building structures

The depth of the pillars are divided into:

- Deep - below the freezing level, depending on the area - 170-200 cm

- Shallow - at the level of 50-70% of the depth of freezing

- Unfinished - with a depth of 40-50 cm

The choice of option depends on the particular soil and temperature zone.

Work plan

- Initially, the plot for the future building is leveled and it is cleaned of debris, then using the level or theodolite, as well as construction twine, tracing is performed: the locations of the posts are determined, and their height is leveled.

- On the basis of the trace carried out, earthwork is carried out: digging a foundation pit, trenches or drilling pits.

In most cases, when a foundation is made of asbestos-cement pipes or other similar materials, drilling pits is nevertheless used.

Important information!

If the building is planned to build a porch, porch, terrace - a separate foundation is equipped for the annex, and it is separated from the main building by a deformation seam.

This is done to avoid deformation of each of the structures due to uneven subsidence or heaving of the soil.

- After the pits are prepared, depending on the soil, a drainage cushion is arranged, which is a layer of sand in 100-200 mm, and on top of it - the same layer of rubble.

If the soil is gravel (with an admixture of fine stone) or coarse sand - you can not arrange a pillow. - Waterproofing spreads over the pillow (for example, roofing material), and the pipe falls to its level. After that, concrete with a gravel fraction begins to be poured through the pipe. The pipe is gradually raised until the entire diameter of the pit is filled with a mixture of 20-30 cm.

The pipe is fixed at this level until the setting of the mortar begins. Until the final solidification has occurred, the reinforcement is pressed through the pipe into the formed base.

It is important not to forget to leave the valve outlets in the upper part for fixing the grillage. The bulk of the cement is poured into the pipe after the final setting of the cushion. - The grillage is mounted according to the technology in accordance with the selected material - by assembling reinforced concrete, pouring the monolith, welding, etc.

It is believed that the foundation of plastic pipes is less practical than from. If this is true for metal (it does not require reinforcement), then asbestos cement does not give a significant gain - after all, it and plastic only play the role of formwork, despite the fact that the polymer is lighter, more resistant to harmful substances and cheaper.

No technical solution can be considered universal and applicable in any conditions, especially with regard to construction. The pipe foundation is not such, however, if it is suitable for a specific building project, it will become an excellent and economical solution, since it costs no more than 18% of the entire construction site, while "classical" foundations can cost 30%.