Very often, an improperly arranged stove chimney creates a fire hazard in a residential building. The products of fuel combustion are not completely removed from the premises and cause carbon monoxide poisoning of the body. Sometimes, due to neglect of the technological features of the work, smoke occurs and reverse thrust is obtained.

Steel chimneys and their properties

There are many varieties of materials for building a chimney in private homes. Pipes are divided depending on the purpose and functionality.

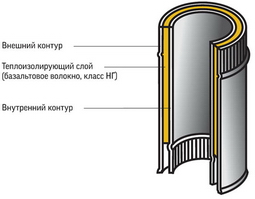

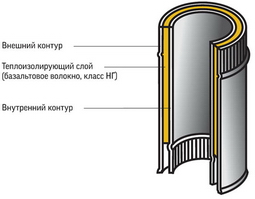

Chimney Sandwich

Insulated double-layer pipes allow the interior to heat up as quickly as possible and contribute to the effective removal of smoke from the combustion source. They are arranged outside the building in cases where it is not possible to carry out the internal wiring of the chimney.

The installation of a chimney sandwich can be ordered by specialized builders, but if you understand all the intricacies of the technology, you can install the smoke channel yourself.

Positive characteristics of a sandwich for a stove chimney

How to choose a chimney sandwich

When purchasing smoke extraction elements, it is required factory certificate with a description of its characteristics, which include the name of the categories of boilers for possible connection, the warranty period and types of fuel. In the absence of a certificate, use the right to purchase elsewhere.

When purchasing smoke extraction elements, it is required factory certificate with a description of its characteristics, which include the name of the categories of boilers for possible connection, the warranty period and types of fuel. In the absence of a certificate, use the right to purchase elsewhere.

For craftsmen who want to create smoke extraction with their own hands, there should be detailed instructions.

Pay attention to the stainless steel from which the sandwich is made. The quality of this material affects the service life and resistance to high temperatures.

The heat insulator inside the cavity must withstand up to 650º without deformation.

For solid fuel boilers, products with laser welded seams and stainless steel inner tube. For boilers using gas fuel, it is allowed to connect the elements using the rolling method and the cavity inside each of the galvanization.

External elements can be made of galvanized steel, polyester, brass, stainless steel.

Sizes of stainless steel sandwiches

When buying pipes, it is required to take into account the diameter of the outlet of the nozzle from the boiler. The corresponding indicator of the pipe should not be less than it. Sandwich pipe should be put on the outlet.

Features of installing chimneys

Double-walled sandwiches solve the problem of condensation on the walls of the chimney in cold weather due to the insulation included in the design. Such isolation prevents soot formation on the inner surface and increase the service life.

To facilitate the installation of the prefabricated structure, fittings are produced for connection, channel rotation and other functions.

Varieties of elements for assembly

- The main length of the chimney is carried out in lengths of 1 and 0.5 m.

- Horizontal sections (beds) are connected using revision tees to eliminate clogging of the pipe.

- A tee for collecting condensate and cleaning the internal cavity is installed at the beginning of the vertical section of the channel. Often this happens immediately after the chimney exits to the outside of the building. One of the outlets of the tee is made opening on the thread to remove condensation moisture.

- The corners for the device for turning the chimney by 90º are made of pipe materials and are insulated with an insulator layer.

- Compensator for a smooth change in the linear dimensions of the sandwich when changing temperatures. In high-rise buildings, it is installed on each floor, and in one-story buildings above the floor.

- The structure of the junction with the roof is designed as a single unit and serves to form the exit of the chimney channel to the roof.

- Knot for eliminating leakage in the outlet of the roof. Installation is carried out around the chimney.

- Tip to protect the channel openings from debris, snow and dust.

How to properly assemble a chimney

outdoor assembly. The first step is a horizontal pipe section from the boiler. A steel sandwich is attached to the chimney pipe using prefabricated elements that are fastened to each other with clamps and crimped. In the middle of the distance of the horizontal section, a tee is inserted for revision.

outdoor assembly. The first step is a horizontal pipe section from the boiler. A steel sandwich is attached to the chimney pipe using prefabricated elements that are fastened to each other with clamps and crimped. In the middle of the distance of the horizontal section, a tee is inserted for revision.

The connection of the subsequent pipe is carried out by putting it on the previous one. You can't change the order otherwise smoke will enter the room.

The horizontal part of the pipe is lowered from the boiler by 3-5 cm so that condensate does not enter the boiler.

In the passage of the sandwich through the wall, insulation is made of non-combustible materials. If the pipe passes through a wooden wall, then it is additionally wrapped with a layer of asbestos. In brick, concrete and clay walls, it is enough to isolate the gap with mounting foam for outdoor use.

It is impossible to connect sandwich pipes at the exit point through the wall. If you accidentally hit this place, it is done pipe cutting to the passage, then a whole section of the sandwich is embedded in the wall.

After the chimney exits the wall to the street, they immediately put a tee to collect condensate, then they arrange the pipe to turn up. The sandwich is fastened to the wall by attaching it to a supporting truss, which is mounted dowels or anchors.

The chimney is assembled to a height above the roof of at least 0.5 m. The pipe is fixed every couple of meters, but sometimes the chimney is fastened more often to prevent bending and sagging of the chimney.

The elevation of the pipe above the roof directly depends on the proximity of the ridge to the chimney outlet to the surface. If the pipe rises more than 2 m, then additional mount it to the roof with a metal cable to give strength to the structure.

The device of the internal smoke channel

All connections are made in the same way as the external assembly, only special attention must be paid to the passage of the chimney through the roof.

Sometimes, for the arrangement of the place of passage, a change in the design of the roof lathing is required. Interfering bars are cut out and transferred to another place. If we talk about interfering beams and rafters, then it is not recommended to break them. In this case, the exit point of the pipe is shifted. This applies to the option when the chimney is already made in the finished building. In new buildings, such problems should not arise.

From below, a pipe is substituted for the prepared passageway, and a pipe is put on top of it. special spigot element, which is fixed to the roofing with self-tapping screws. The junction with the roof is treated with mastic.

The element, in turn, serves as a support for putting on the outer pipe. Along the perimeter, this entire structure is crowned with a special stainless steel skirt. The assembly is uploaded installing a chimney cap. After that, a traction test is carried out.

When installing a chimney from a sandwich pipe, it is necessary to take into account all the little things, so as not to endure trouble from smoke or carbon monoxide later. special attention should be paid for careful sealing of joints and matching pipes in diameter.

When all installation rules are followed, the chimney will serve faithfully for a long time.