In the construction of public buildings, residential buildings or industrial premises, it is necessary to provide ventilation systems. This is due to sanitary and hygienic standards, safety standards and vital necessity. And to put it simply, when installing high-quality ventilation, there will be no unpleasant odors in the apartment, dampness and mold on the walls, and in industrial premises there will be no harmful impurities in the air. Ventilation pipes and fittings are a complex system for smoke removal and air purification in buildings where there is no natural ventilation, for underground structures and high-rise buildings. Specialists in design are engaged in the development and implementation of such systems.

Varieties of ventilation ducts

Plastic ventilation ducts are widely used in all types of premises. Pipes and fittings made of plastic provide the necessary level of tightness of the ventilation system, are not affected by moisture and corrosion. The smooth surface of the air duct reduces the noise level and creates the best conditions for the free passage of the flow of the calculated volume at the required speed. In addition, they do not need regular cleaning, therefore, the life of the ventilation system increases. However, with all their advantages, they can be used in systems with ambient temperatures up to +50°C. When installing plastic pipes, it is worth remembering that passage nodes in concrete or brick floors require the use of a steel sleeve, but the use of roofing felt or roofing felt is also allowed.

Plastic ventilation ducts

Flexible ducts are made of plastic or metal. Mainly used for exhaust ventilation with ambient temperatures from -30°C to +120°C. Ideal for laying in GKL boxes, fitting into any interior. The advantages include the possibility of using corrugated air ducts with a complex layout of the room, as well as ease of installation. Passage units for flexible ventilation ducts also require compliance with installation standards and the use of sleeves, and when laying in walls, additional insulation with a layer of concrete to avoid damage to the tightness. Exhaust pipes for ventilation are brought out through the shaft to the roof or roof.

In industrial enterprises, metal rectangular or square ventilation boxes with numerous connecting elements are more often used. The node or joint of the connection is selected according to the design data.

The installation of steel ventilation ducts has a number of difficulties; the tightness of the system, the quality of sound insulation and its service life depend on the quality of welding or assembly of products. Rectangular or square ventilation ducts make more efficient use of space. However, often the inner corners of the ducts create air resistance and, in order to block the loss of air pressure, it is required to install additional electrical equipment.

An example of the installation of metal ducts

For the exhaust air duct system, sandwich pipes are increasingly being used, which are made of connected two galvanized pipes filled with insulation between them.

The double-walled design of the chimneys ensures that there is no condensate in the pipe and fully complies with fire safety standards, since the insulation is made of refractory material. Double-walled galvanized pipes for ventilation are often installed outside the building, but can also be used for exhaust shafts.

Single-wall pipes for chimneys are used indoors as an independent structure, which is connected to the main chimney, and as a sleeve in existing brick ventilation shafts. The metal chimney duct is made of corrosion-resistant stainless or galvanized steel. In the case of laying pipes in shaft channels, it is required to perform additional insulation of pipes from refractory material, fixing it with galvanizing.

Estimated data

To maintain human health, GOSTs, SANPiNs were developed, which regulate the indicators of the ventilation system. Ventilation performance begins with the calculation of air exchange and air distribution network, the choice of air distributors (grilles). To do this, you need to know the purpose and area of \u200b\u200bthe premises, as well as draw up a diagram for laying air ducts. Air diffusers are selected from catalogs according to air flow and noise level. Taking into account all the characteristics of the above calculations, a heater, a supply unit is selected.

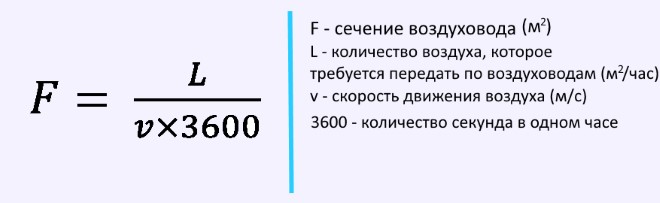

Focusing on the normative data and dimensions of the premises, in order to create the necessary air exchange at a given rate, experts calculate the area or diameters of the air ducts. It must be understood that the cross-sectional area of the pipe directly affects the flow and speed of air in the duct. Reaching the required air velocity parameters, one should not forget about the sound insulation of flat or flexible metal ventilation ducts. Additional noise in corrugated piping or rigid ducts can be reduced by using sound absorbing sandwich board insulation, reducing the number of right angles, sharp bends and transitions from one pipe diameter to another.

When installing the pipeline of the ventilation system, taking into account the peculiarities of the environment of the room, operating conditions, round, square or flexible ventilation ducts made of plastic or steel structures are used. The cost of the ventilation system depends on the quality of the material used, on the thickness of the metal and the number of fittings. Welded black steel ducts will cost less than galvanized pipes. Shaped parts of plastic or metal pipelines allow you to assemble a ventilation and smoke exhaust route with numerous turns and intersections with other communications.

Briefly about the important

Summing up, we highlight for ourselves the main requirements for the design and installation of ventilation systems:

- Air ducts for ventilation can be made of plastic or metal, depending on the environment in which they are laid. The quality of the material does not affect the air circulation.

- When laying pipes in ceilings and walls, it is important to remember that the passage nodes must be protected by a steel sleeve or other wrapping material.

- The formula for calculating the cross section of the area of ventilation pipelines is used from reference books for design or SNiPs.

- Ventilation ducts (material and number of fittings) are used based on the type of buildings and the tasks set by the designers.

- Do not forget about soundproofing materials, as well as comply with the requirements for fixing air ducts to reduce additional noise in the room.

- Ventilation ducts can be laid not only indoors, but also in the channels of existing mines, as well as outside the building.

- A flexible duct is used when installing a complex ventilation line and for solving any design solutions, while flat ducts are used mainly for industrial premises.