The ideal option for heating a country or private house as an off-season heater would be boilers operating on a liquefied form of gas. The advantages of such boilers are high efficiency, efficiency and ease of use.

The LPG boiler does not have fundamental differences in design, with the exception of special nozzles, which can often be supplied as a set.

The difference is that the nozzles for such boilers are made taking into account the impact of a stronger working pressure.

Tip: it is better to provide the boiler commissioning work to a specialist, even taking into account the fact that they are available for the average layman. Thus, you can be sure that the master will do all the work correctly and guarantee the quality, as well as the safety of connecting the boiler.

Advantages and disadvantages of such equipment

Compared to other available heating options, LPG boilers still have a number of undeniable advantages:

- Independence from tariffs, well, utility services and a centralized heating system.

- The boiler efficiency reaches 96%.

- Universality.

The universality is that the boiler can operate not only on a liquefied fuel source, but also on ordinary bottled gas. To do this, it is only worth changing the burner to a model with a smaller nozzle diameter.

Also the second universal quality of such boilers is their functional practicality. That is, they can be used not only as a heating device, but also for heating water and other domestic needs.

Disadvantages are also available

For all its “positivity” and convenience, these boilers also have some disadvantages, characterized by 2 points:

- The process of connecting each cylinder is done manually and requires not only scrupulous care, but also caution in terms of safety.

- For full continuous operation it is necessary to have several cylinders with liquefied gas in stock.

The recommendation of experts: for storage of cylinders it is better to allocate a special ventilated room, preferably with a separate exit. It is strictly forbidden to store cylinders in the basement or basement.

What must be considered when choosing equipment?

First of all, you need to decide what functions the boiler will perform.

There are 2 types of modifications: single-circuit and double-circuit. The first ones are intended only for heating, and the second ones also allow you to warm water, in addition to heating the room.

There are also differences in the installation method: wall and floor models. The combustion chamber can also be of two types: open and closed. It all depends on the preferences and user convenience.

When buying equipment, the first thing to do is to focus on quality characteristics:

- The equipment must function in low pressure conditions. This will allow maximum gas consumption in the tank.

- Efficiency should be at the level of 90 -96%.

Equipment with such characteristics will be able to fully justify the expected demands of efficiency and effectiveness (consumption - approximately 2 cylinders / week for heating an area of \u200b\u200b100 m2).

In principle, if there is a balloon gas boiler in the household, there is no need to buy another one. Simply put the nozzles with a smaller diameter and set up the automation system and fittings. For a greater guarantee of success, it is better to consult a specialist.

Calculation of the flow of liquefied gas

When calculating the gas flow rate, it is necessary to be guided, first of all, by the evaporation surface area. The higher this indicator, the faster the liquid is converted to steam.

The main indicators for calculating the flow rate are the density, calorific value of liquefied gas (0.52 kg / l and 23500 kJ, respectively) and the thermal energy that is released during the combustion of 1 liter of fuel (6.53 kWh).For clarity, it is worth taking the average cost of 1 liter of fuel (+ \\ - 16 r) and the average rate of cylinder displacement (in the region of 42 l \u003d 22 kg) \u003d the cost of 1 cylinder.

The average fuel consumption indicator () is 0.12 kg / h per 1 kW of heat (boiler 12-15 kW) \u003d the average indicator is 1.2-1.7 kg / h of fuel.

This is quite enough for heating up to 140 square meters.

Experts advise giving preference to horizontal devices, it is believed that they have greater economic and productive benefits.

Connection diagrams of single-circuit and double-circuit boilers

Consider a single-circuit boiler scheme.

The circuit of a single-circuit boiler is given

In this embodiment, the coolant circulates through the heating system of the room and rotates back, where it is reheated. The presence of an expansion tank and a safety valve is provided for bleeding pressure.

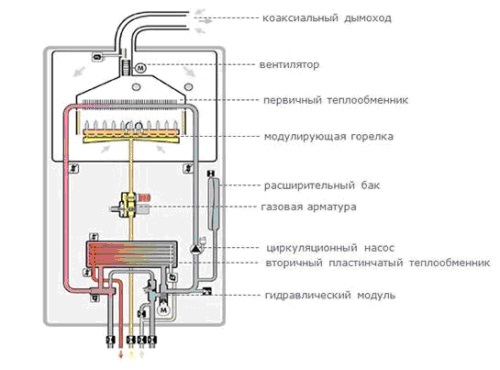

As for double-circuit boilers, the main difference is that it has two heat exchangers.

One is for the heating system, and the other is for domestic water supply. To a greater extent they relate to wall boilers for liquefied gas.

And they have such a mounting scheme.

This is a dual circuit diagram.

The location of the 5 pipes inside is necessary for (from left to right):

- Hot coolant for the heating system.

- Hot water for domestic hot water.

- Pipe for gas.

- Cold water for a heat exchanger that heats it for hot water.

- Heat carrier from the heating system, going to pre-heating.

Prices for domestic-made boilers

In general, the prices of liquefied gas boilers have a fairly wide range of variation.

It all depends on the power of the device and the needs of the user. But if we take medium-sized models for private use, they are distinguished by their availability and relatively low cost.

As an example, we can cite such domestic models as AOGV 11.5 (120m 2) - worth about 17,000 rubles, KSGV "LUCH" - from 10,000 rubles. or Hearth KSGV-12 SP - from 13 000 r.

Note: prices are indicated at the time of writing - 2015.

The video below shows how to convert the Baxi Eco Compact to LPG.

We hope that the material was useful to you. We will be very grateful if you share this article with your friends on social networks. To do this, click on the buttons below.

Have a nice day!

If it is not possible to connect to the main gas pipeline, heating units operating on liquefied gas are one of the options for efficient space heating. The use of liquefied fuel mixture for heating buildings is similar to heating with main gas, but requires constant cash costs for the purchase of fuel.

Design features of liquefied gas heat generators

The difference between the design of a liquefied gas boiler and a conventional gas apparatus operating from a gas main consists in the use of a nozzle designed for a higher fuel pressure.

Some brands of boilers were originally designed for the possibility of switching to liquefied fuel by replacing a standard nozzle with a device of a smaller diameter. To implement this measure, special nozzles and additional structural elements for the boiler will be needed. Sometimes they come complete with the unit, sometimes you have to purchase them yourself. The cost of replacing the nozzle with the purchase of the required parts will be approximately 2-3 thousand rubles. It should be noted that such reconfiguration of the boiler must be carried out by specially trained personnel.

Types and characteristics of liquefied gas

Until recently, liquefied natural gas was used as the main fuel for liquefied gas boilers. But its storage and use required significant costs, which were justified only when heating entire residential complexes. Gradually, a more economical hydrocarbon gas mixture began to be used to organize autonomous heating of individual housing. Its main components: isobutane, butylene, isobutylene, N-butane, propylene.

A slight increase in the pressure of the propane-butane mixture causes its transition to a liquid state, which makes it easy to transport and store. As the pressure decreases and the temperature rises, the mixture becomes gaseous.

Advantages of using propane-butane liquefied gas for heating or other needs of the population:

- The production and processing of this gas mixture is not associated with high costs or technical difficulties.

- Propane-butane gas is characterized by a small amount of harmful emissions into the atmosphere.

Difficulties in using liquefied gas for heating:

- When filling cylinders at a gas station, there is a chance of acquiring a poor-quality, diluted product, which will lead to unstable and inefficient functioning of the unit.

- Replacing the cylinder is carried out manually, this event requires the application of physical force, so it can not be performed by everyone.

- Liquefied gas is an explosive product that requires careful handling.

- To ensure complete combustion of the propane-butane mixture, it is necessary to organize an effective ventilation system in the boiler room.

Features of the organization of autonomous heating using liquefied gas

When choosing a unit designed to operate on liquefied gas, it is necessary to pay attention to its ability to operate at low pressure. This will allow to completely use up the gas pumped into the cylinder.

The high efficiency of the unit plays a big role when choosing a conventional gas boiler, but for an apparatus running on a liquefied gas mixture, this indicator is especially important. The installation of a low efficiency unit will lead to the economic inexpediency of using bottled gas.

Based on the results of calculations and analysis of practice, we can conclude that for heating and supplying hot water for house building with an area of \u200b\u200babout 100 m2, on average, two cylinders are required per week. That is, about 8-9 gas cylinders are consumed per month of the heating period. With the cost of refueling a tank of about 500 rubles, heating costs per month will be about 4.0-4.5 thousand rubles. If you need to hire a vehicle to deliver fuel, the costs will be even higher.

The liquefied gas heating system has both advantages and disadvantages. But if there is a prospect of supplying main gas, the use of bottled liquefied fuel is the most rational solution. Replacing bottled gas with a trunk gas will be a simple, inexpensive, and quick action.

Today, many private houses have liquefied gas heating boilers, bottled gas is used in the dachas, but few understand what liquefied gas is. This is a liquefied hydrocarbon gas mixture (LPG). The main components of such a gas are propane, butylene, isobutane, propylene, isobutylene and H-butane.

Until recently, autonomous gas supply systems, which included heating boilers for liquefied gas, used methane (liquefied natural gas), the storage and use of which was associated with significant costs and technical difficulties that were economically justified only when heating entire residential areas. Therefore, today a more economical mixture of butane and technical propane is used.

Scope of LPG

Due to the fact that gas production and processing are not associated with high costs and this gas mixture is characterized by low emissions of harmful substances, liquefied gas has been widely used both in production and for solving household needs of the population. So, for example, propane - butane mixture is used for the manufacture of aerosols, it is used by heating boilers using liquefied gas, it is used as automobile fuel, as well as a heat source.

LPG heating boilers

What distinguishes a conventional gas-fired boiler from a device operating on liquefied or bottled gas? There are practically no structural differences, except that the boiler with bottled gas has a nozzle designed for a higher gas pressure. For some brands of gas boilers, to switch to liquefied fuel, it is enough to reconfigure the nozzles taking into account the pressure of the liquefied gas. For this, special nozzles and spare parts are used. This procedure will cost about 2-3 thousand rubles. Many boiler manufacturers take into account possible changes in the operating modes of their products and supply special kits for reconfiguring heating boilers.

Attention! The operation for reconfiguring the nozzles should only be carried out by specially trained personnel.

Recommended! In places where gas supply is not possible or the main line is still under construction, you can use a cast-iron floor heating boiler with an oil burner. Further transition to gas heating is carried out by the usual replacement of the burner.

The most important parameters of a liquefied gas boiler

The primary parameter characterizing a bottled gas boiler is the possibility of its operation at low pressure, which will maximize the volume of gas contained in the cylinder. A good indicator is the ability of the boiler to work with a pressure of about 3mbar.

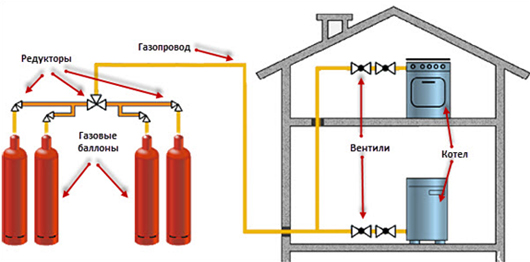

To change the operating mode and switch to liquefied gas, the gas-fired boiler needs to be replaced with standard nozzles with special ones with a smaller diameter. Such nozzles can be supplied by manufacturers complete with boilers, or purchased separately. It is undesirable to connect one cylinder to the boiler. It is better to use a group of several at once, otherwise the cylinders will have to be changed every other day.

The practice of use and the calculations made show that, on average, 2 cylinders of liquefied gas per week are needed for heating and providing hot water for a house with an area of \u200b\u200babout 100 square meters. This means that during the heating season, the monthly operation of the boiler will be provided with 8-9 cylinders. The cost of refueling one cylinder will be approximately 500 rubles, and the total monthly fuel costs will be 4 - 4.5 thousand rubles. If you do not carry the cylinders in person, then the costs will increase due to delivery. As a result, the amount obtained is not small, but it is unlikely that the use of other energy sources will be cheaper.

Alternatively, a diesel-fired boiler can be installed. After all, after a gas boiler, this is one of the most acceptable options. However, diesel is also an expensive fuel, a diesel boiler constantly smokes and needs a good extract. In addition, it is less reliable during operation and can not do without special maintenance. At the initial stage of operation, a diesel heating system is expensive, because in addition to the boiler, it is necessary to purchase a significant tank for storing fuel, install cleaning filters and dehumidifiers.

Practical disadvantages of using balloon gas

Of course, boilers running on liquefied gas have a considerable number of minuses:

- Filling gas cylinders at a gas station, unfortunately, there is a possibility of acquiring a diluted product, which will result in unstable and low-efficiency operation of a gas boiler. The reason is the banal theft of gas.

- Another disadvantage in the use of bottled gas is the need for constant control of the fuel level. On average, heating and hot water supply for a house of 100 - 200 square meters. m requires 2-3 cylinders of 50 liters of gas per week. The expense is very significant, so you will have to visit the gas station weekly, which is also not very convenient, or to make a stock for 8-10 cylinders, which requires additional space.

- Replacing and connecting the cylinder is done manually, which requires a certain physical strength.

- Liquefied gas is an increased explosion hazard.

- For complete combustion of the gas mixture, good ventilation of the boiler room is required.

- The price of this type of fuel in recent years has a tendency to increase.

It is unambiguous to conclude that bottled gas represents the best alternative to network gas, most likely, is impossible. This fuel system has positive and negative sides, but if there is hope in the future to carry out main gas, installing a boiler using bottled gas is probably a rational solution, since replacing the bottled gas with a gas supply will be simple, quick and practically unrelated to cash costs.

Use of materials is allowed only if there is an indexed link to a page with the material.

Judging by the numerous reviews, the most economical heating boiler is a gas one that runs on natural gas. Today, this type of fuel is not in vain considered the most affordable and cheapest. If it is not possible to connect to the gas main - remoteness from settlements, non-gasified area, the closest and most advantageous alternative is liquefied gas.

Gas heating boilers

The essence of the device, if we consider an approximate scheme, is quite simple: gas - natural or liquefied, enters the combustion chamber, mixes with air and burns on the burner, the heat received through the heat exchanger is transferred to the heat carrier - water or antifreeze. Combustion products are discharged through a chimney. Since the gas burns out completely, there is no need for periodic cleaning.

- From a structural point of view, the difference between boilers operating on natural or liquefied gas is only the burner device: in the second case, the nozzle diameter is much lower.

Most models can be converted for the consumption of a particular type of gaseous fuel, which is very convenient, judging by the reviews of consumers. However, one should pay attention to such a characteristic of the heating boiler as the ability to work at low gas pressure - 0.005 MPa. Otherwise, the cylinders will not be completely consumed. The photo shows a gas floor apparatus.

- The second feature should be considered fuel: bottled gas is acquired, transported to the place of use and stored. Moreover, both ready-to-use and waste containers should be stored outside the residential building in the utility room. At high fuel consumption, special underground tanks with a capacity of up to 6 thousand liters can be equipped. Permission is required for this.

The propanobutane mixture used as fuel is quite safe. It ignites only when mixed with oxygen in the presence of an open flame. However, a leak is also dangerous for the human body: a small concentration of gas in the air has a toxic effect. The mixture is odorless, therefore, a sharp smelling substance is added to the liquefied gas to prevent possible leakage.

Settlements and expenses

The stumbling block when choosing, as a rule, is the availability of fuel. At first glance, it’s easier to get firewood or coal for a solid fuel boiler; moreover, this fuel does not require such careful and careful storage. However, the effectiveness of the heater itself in this case depends heavily on the quality of the raw materials: low calorie content, high gumminess, humidity, and so on will negate all the advantages of accessibility, as the reviews indicate. At the same time, soot and soot are emitted much more, which means a much more frequent cleaning of both the combustion chamber and the chimney.

- Liquefied gas has the same composition and standard connection, it burns completely, providing high efficiency of the device. One cylinder contains 21 kg of the mixture. Its consumption depends on the area of \u200b\u200bthe heated premises, the degree of insulation of the building, the difference between the temperature outside the house and inside, and the like.

With approximate calculations, it is assumed that for heating 10 sq m of a building with a ceiling height of up to 3 m and average insulation, 1 kW is required. This amount is provided by the combustion of 0.1 kg of liquefied gas. To compare firewood - dry and high-calorie, you need about 0.4 kg.

With a conditional area of \u200b\u200b200 sq m, heating will require 20 kW / h, or 20 * 24 \u003d 480 kW per day. Since at night heating is required to a much lesser extent, and more than half the time the boiler works to maintain the temperature, in reality this value is divided approximately in half - 240 kW per day. This means that for heating during the month of the autumn-winter season, with such a need, 240/10 * 0.1 * 30/21 \u003d 3.43 bottles will be used up. Multiplying the amount received by the cost, it is easy to calculate costs.

LPG boilers: classification

The devices are available in various modifications, satisfying one or another needs of consumers.

According to the type of burner, three groups are distinguished.

- Flare and fan burners - the device is very close to liquid fuel and is easily converted to diesel fuel. The fan, as the name implies, is equipped with a supercharged fan, which ensures the supply of oxygen to the burner, and, therefore, complete efficient combustion. The photo shows a sample.

- Atmospheric burner - combustion occurs without a special air supply. This type assumes constant steady pressure, which is not always possible. But such a device is independent of power supply, while the operation of the fan requires current.

2017-04-03 Julia Chizhikova

Features

The propane boiler operates on the same principle as when supplying gas from the main. The difference is that the supply comes from cylinders that need periodic refueling. This type of heating is used, as a rule, in small areas, or if it is not necessary to heat the room on an ongoing basis.

These devices do not have significant design features, however, they have a nozzle that is designed to work with high pressure. In order to install and connect the device, we recommend contacting a specialist. Although this process is not very complicated and, observing the safety rules, this can be done independently.

Installed heating boilers operating on liquefied propane gas, in the same way as when connected to a gas pipeline. One of the disadvantages of this equipment is the need for frequent refueling. But in this situation, there is a way out, you can connect up to 10 cylinders to the individual gas supply system.

This is done using a ramp, it makes it possible to be fed from 10 cylinders at a time. It has the appearance of a two-shoulder separating collector. Initially, propane gas is used from the main cylinder, then when propane runs out in it, it automatically switches to the reserve tank.

In order for the device to be supplied with optimal working pressure, be sure to install a gas pressure regulator, it will allow the heating system to work without interruption.

Fuel consumption

You will be able to find out complete information on the selection, operation and maintenance of gas boilers of all manufacturers, if you transfer.

Well, of course, the question arises, but what is the consumption of this device? Accurate calculations can be made with specific instructions from a specific boiler model on hand. However, there is an average calculation, if you need to heat a house with an area of \u200b\u200bone hundred square meters, which has warm, windproof windows, good windows without cracks, your consumption will be approximately two cylinders for seven days.

Cylinder Storage Section

Cylinder Storage Section

Thus, for one month you need about 9 cylinders for heating a house with an area of \u200b\u200b100 m2. Your system should be equipped with at least 4 gas tanks, this will make it possible to comfortably heat the house and not to stay in the cold in the middle of the night.

The use of heating of this kind makes it possible to save money, rather than if you used electricity. However, the cheapest way is to use gas from the central highway.

Disadvantages:

Advantages:

- Compared to heating using electricity, we have low cost.

- High ratio useful action.

- Ease of use. No need to obtain project documentation,

- Availability of equipment. The market offers a wide variety of boiler models.

Choosing a model when buying

You can find out the whole truth about the conspiracy related to the selection, operation and maintenance of heating boilers of all manufacturers and models.

Before you go to the store and buy a device, you must clearly define for yourself the requirements put forward by your device, namely:

How to convert a boiler to propane from cylinders

If you want to know about which heating boilers you should not choose, about the subtleties and nuances of their installation and connection, as well as hidden information on the proper maintenance of all manufacturers and models, then go here -.

You can find a list of answers to tricky and topical questions of people who took a chance on their own skin, chose and purchased a new or second-hand boiler.

In order for the gas boiler to work on propane, it is necessary to perform some steps for the conversion of the device. However, not every device can be converted, it must be written in the technical documentation that it can work with a gas pressure of 3-4 mbar.

So, if everything is normal with the documentation, consider how to remake it to work with propane (G 31):

Safety rules for the operation of the boiler:

- It is not allowed to store or install cylinders in the same room as the boiler. They must be installed on the street or in an adjacent room in an equipped closet, at a distance of at least two meters from the boiler.

- Do not store empty containers in the building.

- When freezing cylinders not allowed to heat them with fire. It is necessary to carry out insulation measures of the cabinet with non-combustible heat-insulating materials.

- Every four years is necessary pass cylinders for inspection.